LED bulb

A technology for LED bulbs and radiators, which is applied in lampshades, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve the problems of short creepage distance, unreachable, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

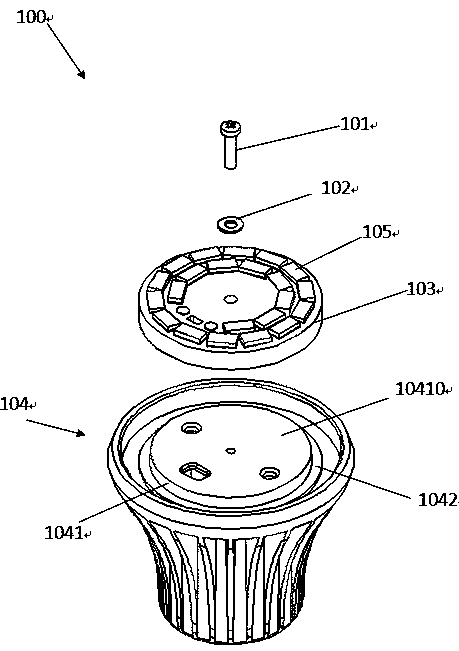

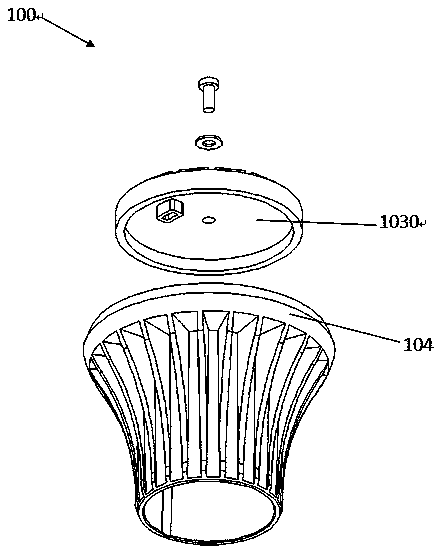

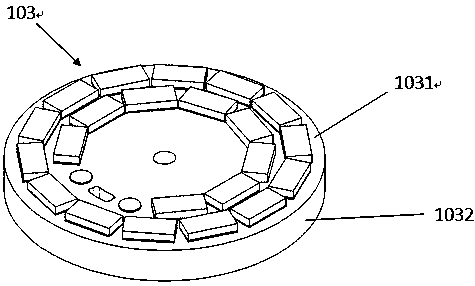

[0011] refer to Figure 1 to Figure 3 As shown, the figure shows the first preferred embodiment of the present invention. In this embodiment, the LED bulb 100 includes a heat sink 104 , a ceramic substrate 103 in contact with the heat sink 104 , and an LED light source 105 mounted on the ceramic substrate 103 .

[0012] The heat sink 104 has a protrusion 1041 , and the protrusion 1041 is connected with the ceramic substrate 103 to form a first connection surface 10410 . The ceramic substrate 103 has a second connection surface 1030 connected to the protrusion 1041 , and the area of the first connection surface 10410 of the protrusion 1041 is smaller than the area of the second connection surface 1030 of the ceramic substrate 103 . The radiator 104 further includes a main body 1042 connected to the boss 1041 , the main body 1042 of the radiator 104 and the boss 1041 form a stepped internal structure of the radiator 104 .

[0013] The ceramic substrate 103 includes a flat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com