Identifying system and method for billets on blanking production line of train wheels

A production line and steel billet technology, applied in the steel billet identification system of the train wheel blanking production line and its identification field, can solve the problems of difficult quality assurance, high labor intensity, unique product correspondence, etc., and achieve the goal of improving the pass rate of off-line and generating product database Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

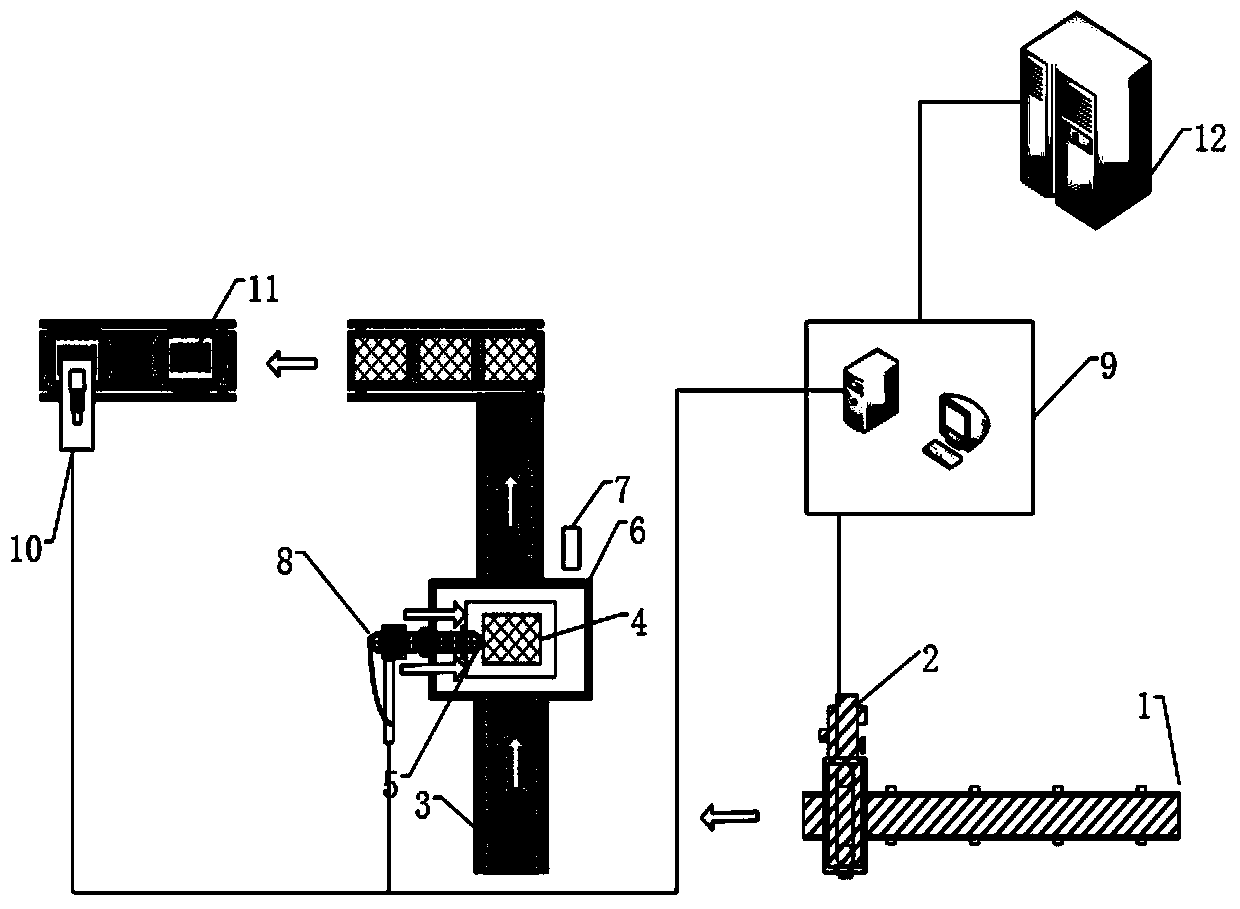

[0028] Such as figure 1As shown, a steel billet marking system for a train wheel unloading production line is composed of a coding marking subsystem and a scanning identification subsystem. , industrial computer and display 9, photoelectric tube 7, billet transmission device, signal communication module, drive control module, data acquisition and processing module, alarm module, the scanning identification subsystem is composed of Microscan QX Hawk image scanner 10, industrial control Machine and display 9. Worldpu FQ-400×400W industrial parallel light source, cooling fan, fixed bracket, signal communication module, drive control module, and alarm module. The industrial computer and display 9 respectively use Advantech IPC-610H (3.0GHz / 1GB / 160GB / 6007LV) and Samsung S24C370HL.

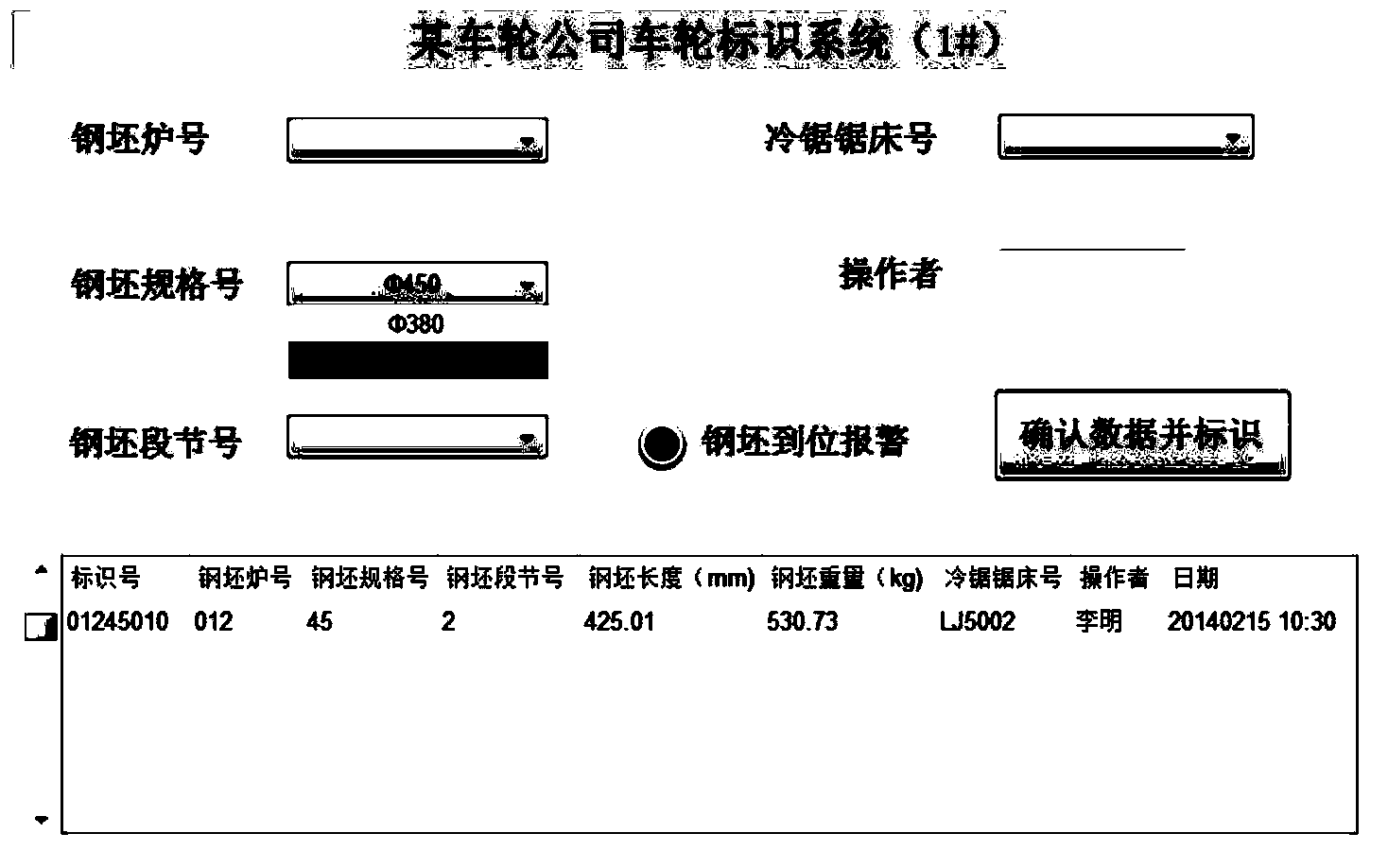

[0029] The identification code is composed of a barcode and eight Arabic numerals below it. The barcode is uniquely corresponding to the eight Arabic numerals below it. For example, the Arabic numerals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com