Banding belt structure for limiting structural displacement of high-temperature gas cooled reactor graphite core

A high-temperature gas-cooled reactor and tie-up belt technology, which is applied in the direction of moderator/core structure, greenhouse gas reduction, reactor, etc. Replacement, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

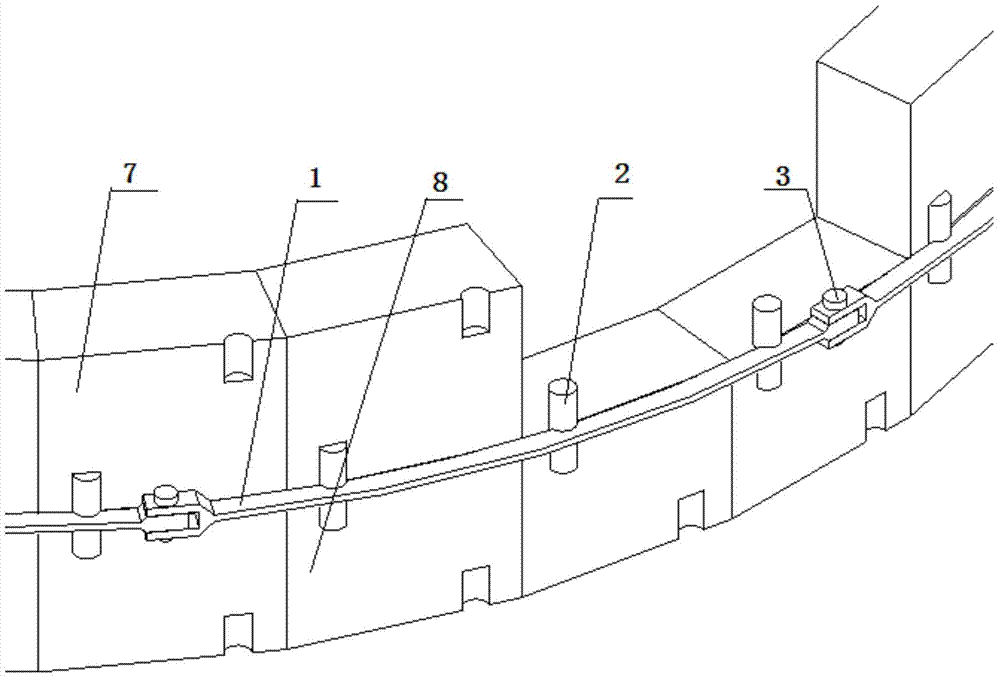

[0022] see figure 1 , the present invention provides a clamping belt structure for limiting the displacement of the graphite core structure of a high temperature gas-cooled reactor, which is used to limit the graphite core structure from falling apart due to excessive displacement under high temperature, radiation, earthquake and other loads. Its construction is made of low alloy materials that can withstand high temperatures. Typically, a clamping belt can withstand a force of about 132 tons at an operating temperature of 250 degrees, which is equivalent to being able to withstand a pressure difference of about 66kPa inside and outside the graphite structure.

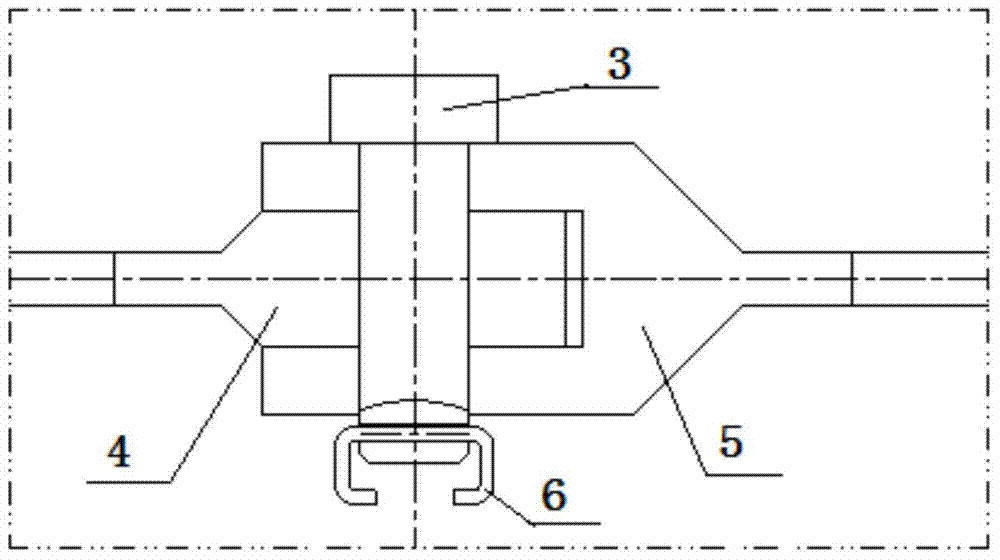

[0023] A great innovation of the present invention lies in the structural design of the tightening band.

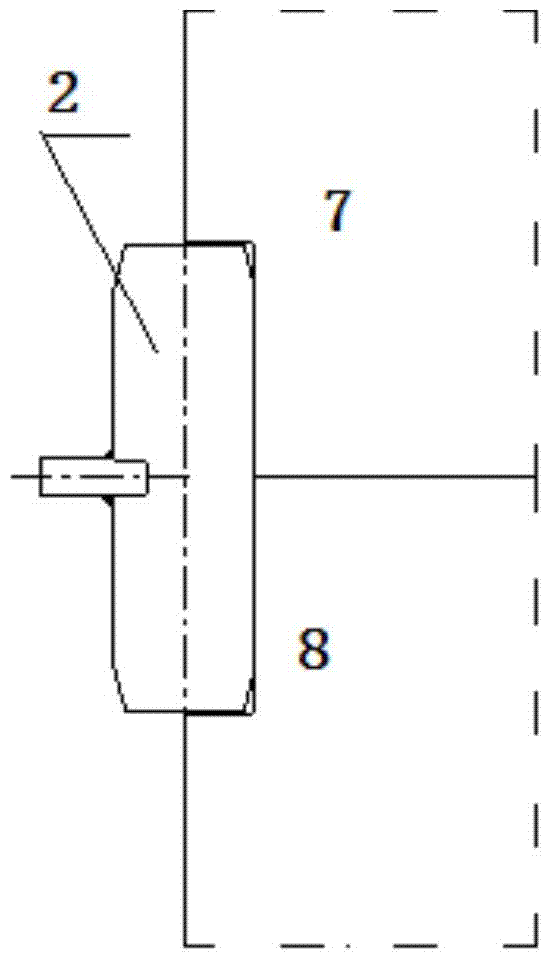

[0024] Such as figure 1 As shown, the clamping belt is composed of 10 clamping belt sector ring units that are movably connected to each other to form a ring structure, and is wound outside the graphite core str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com