Organic light emitting diode display pane

A technology for light-emitting diodes and display panels, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of narrow auxiliary electrode trace width and large trace resistance, and achieves favorable voltage drop, increased contact area, The effect of reducing trace resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

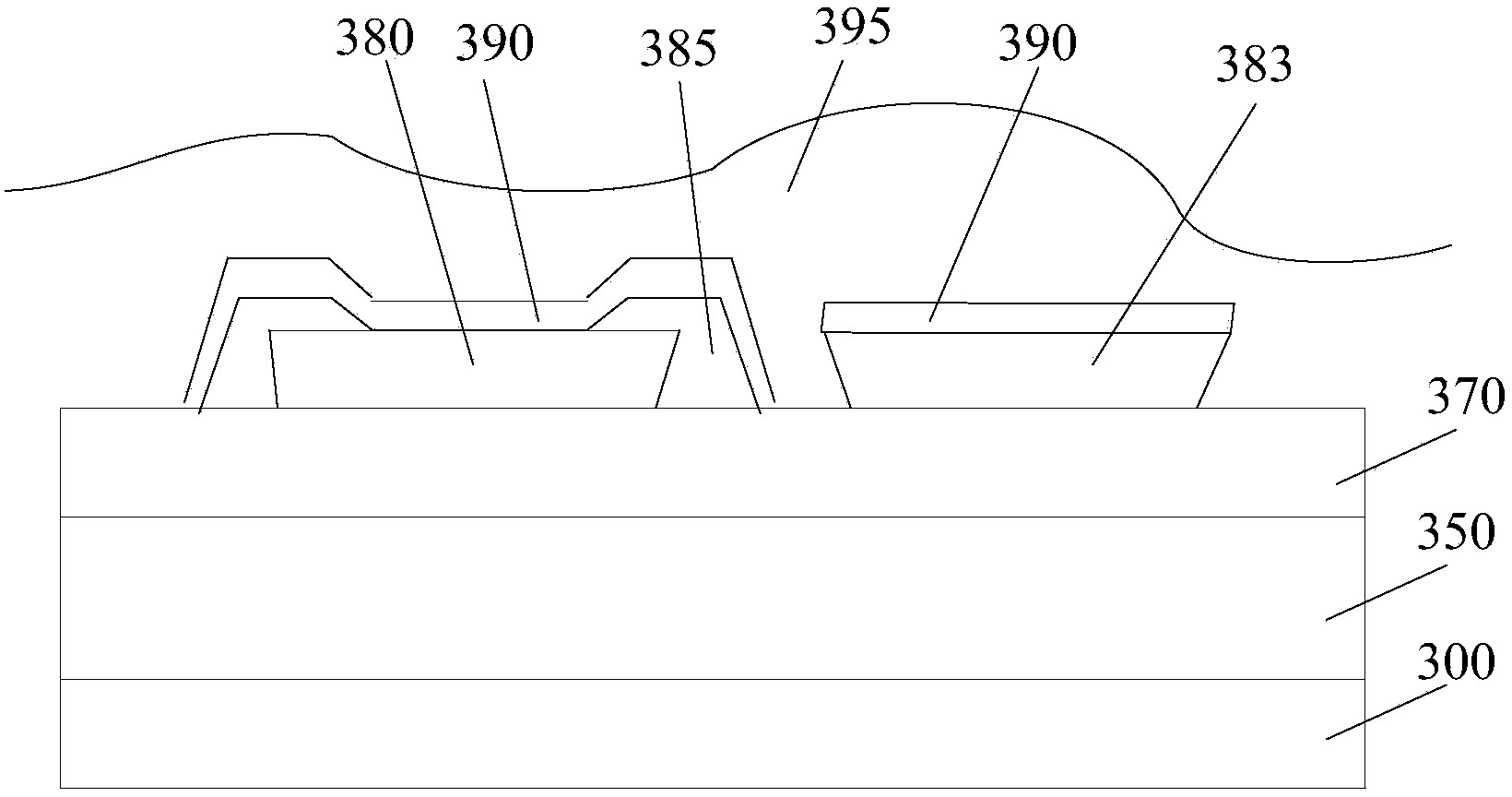

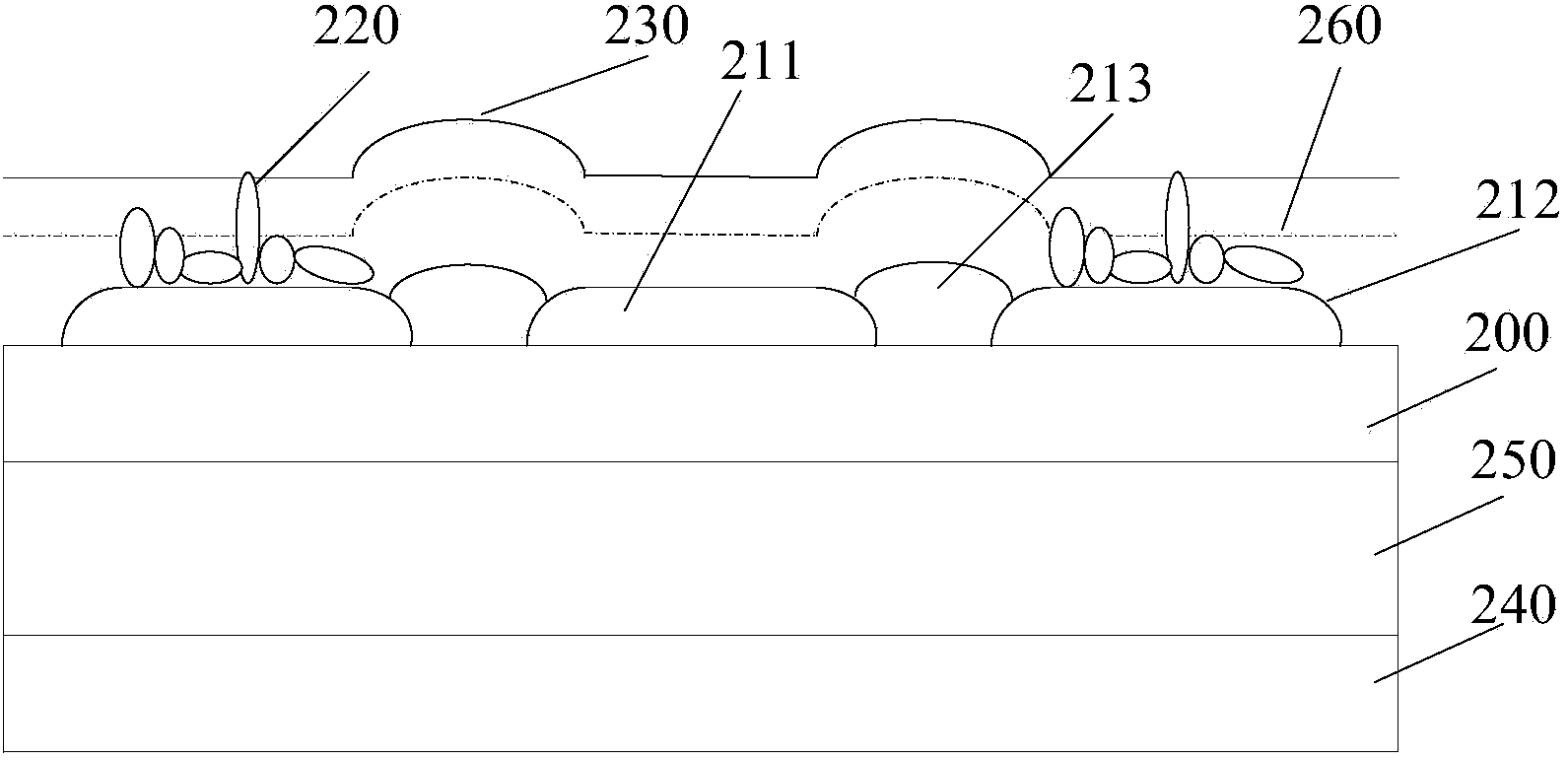

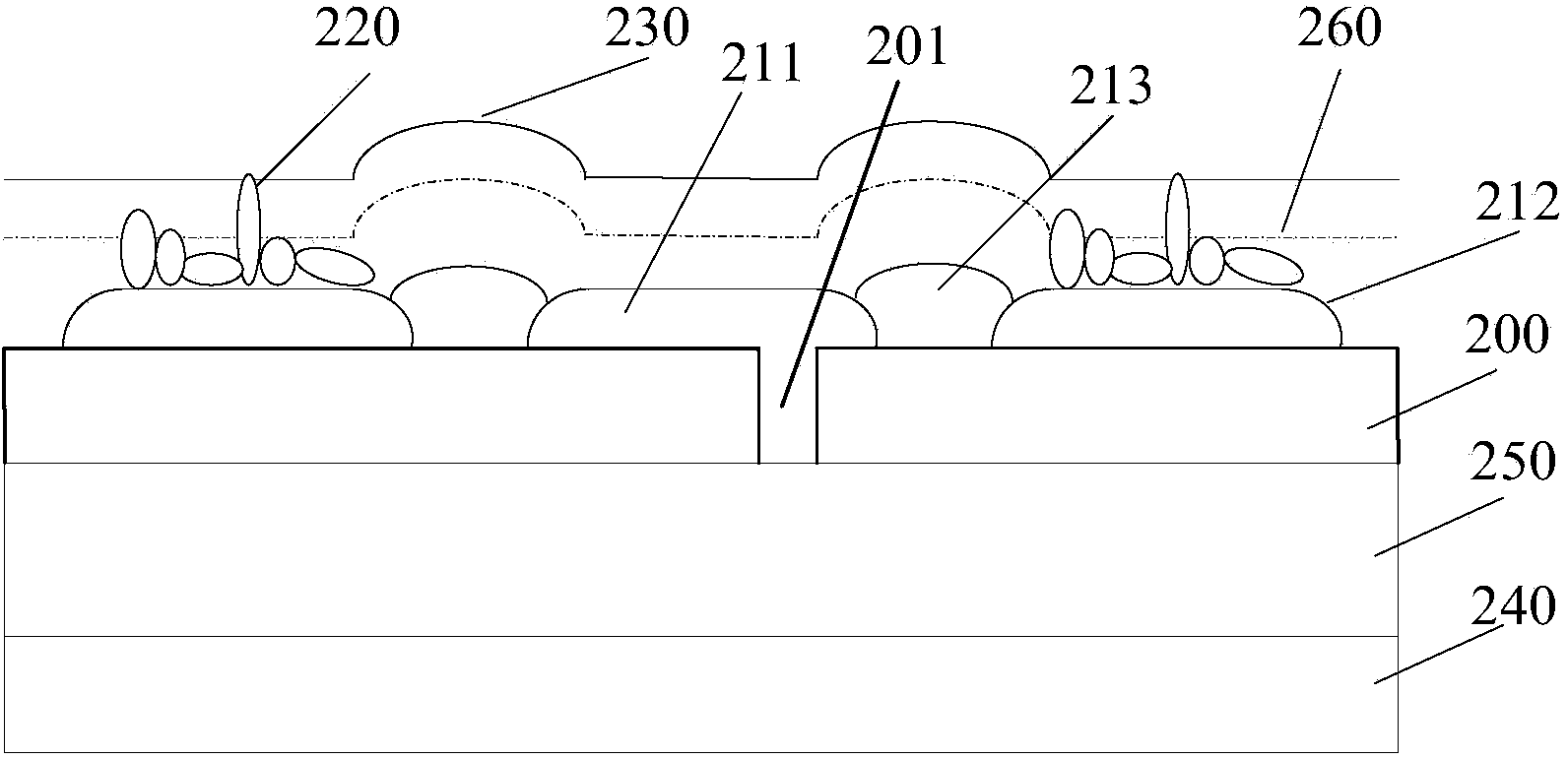

[0025] refer to figure 2 , which shows the structure diagram of the OLED display panel provided by Embodiment 1 of the present invention.

[0026] This embodiment provides a top-emitting AMOLED display panel, including: a planarization layer 200, an opaque electrode 211, an auxiliary electrode 212, a pixel definition layer 213, a conductive functional layer 220, a transparent electrode 230, a base substrate 240, and an organic functional layer 250 and an insulating organic layer 260 .

[0027] Wherein, the substrate 240 is basically located at the bottom of the OLED display panel, and an organic functional layer 250 is arranged on it, and the organic functional layer 250 is covered with a planarization layer 200; an opaque electrode 211 and an auxiliary electrode 212 are arranged on the planarization layer 200; The opaque electrode 211 and the auxiliary electrode 212 are covered with an insulating organic layer 260 ; the insulating organic layer 260 is covered with a transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com