Light-emitting device

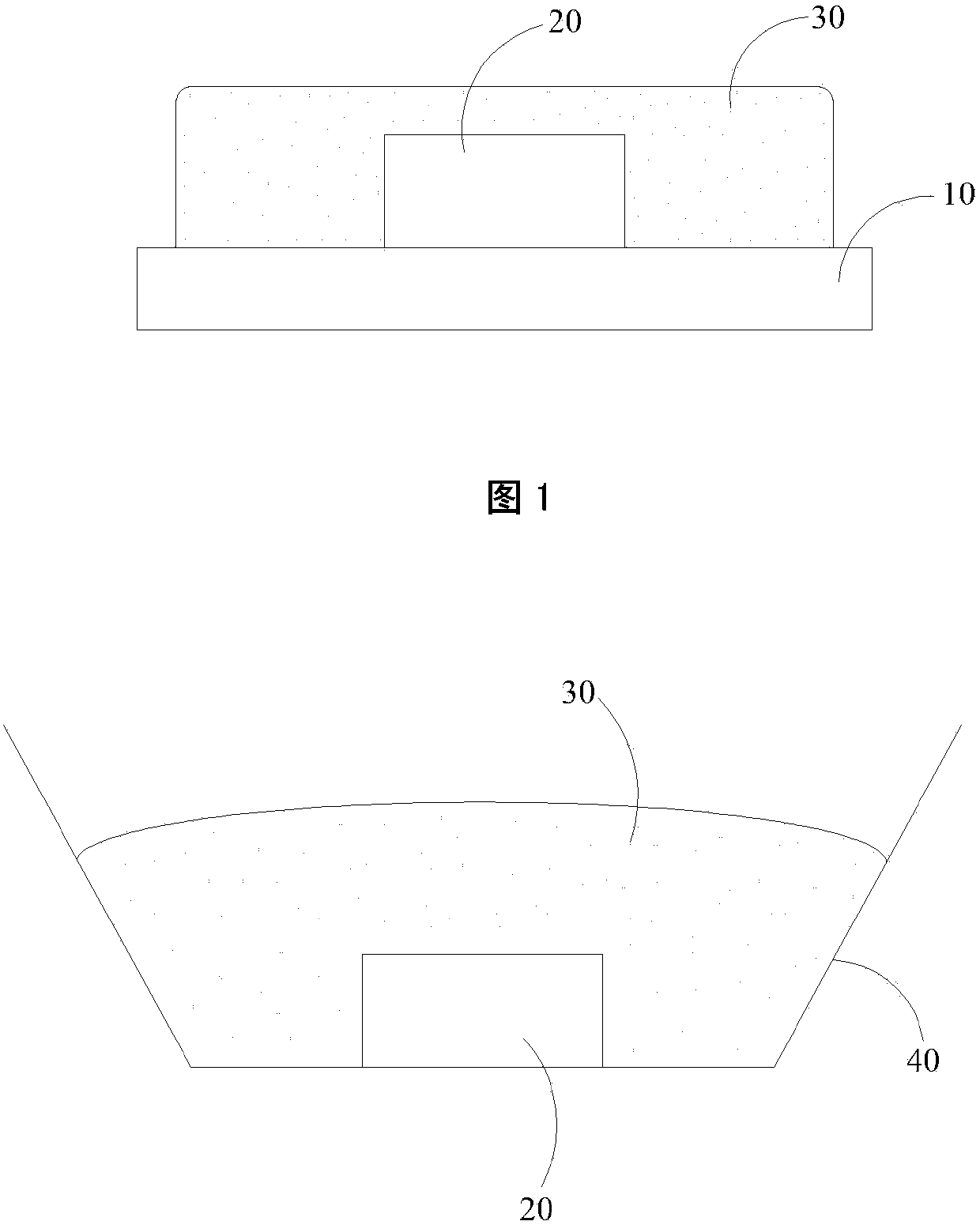

A light-emitting device and a technology of light-emitting diodes, which are applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven thickness, yellow halo, and uneven color temperature of the phosphor layer 30 of light-emitting diode chips, so as to reduce the yellow halo phenomenon and Spatial color shift phenomenon, reduce color temperature difference, uniform illumination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The detailed content and technical description of the present invention are further described by examples, but it should be understood that these examples are only for illustrative purposes, and should not be construed as limitations on the implementation of the present invention.

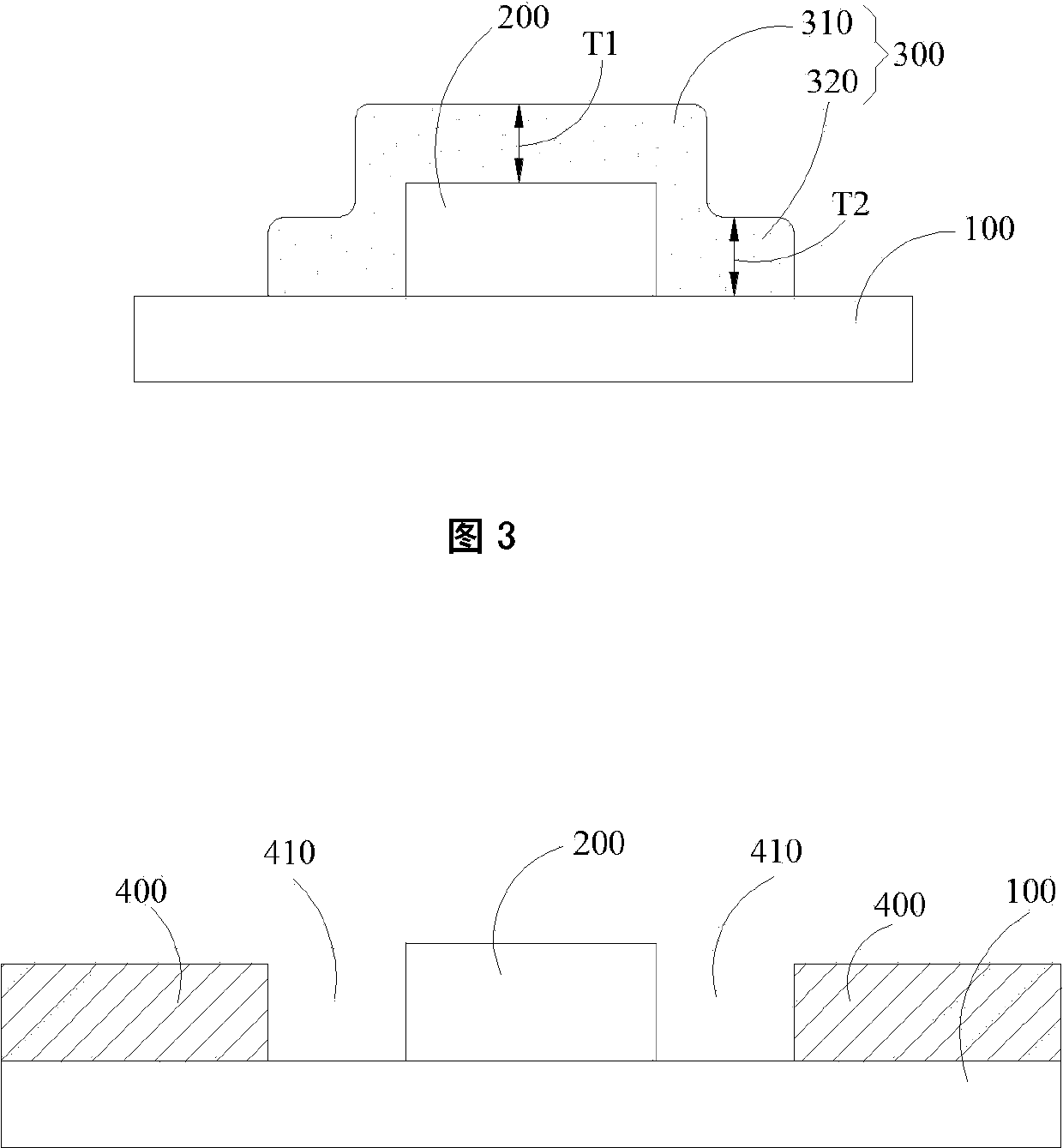

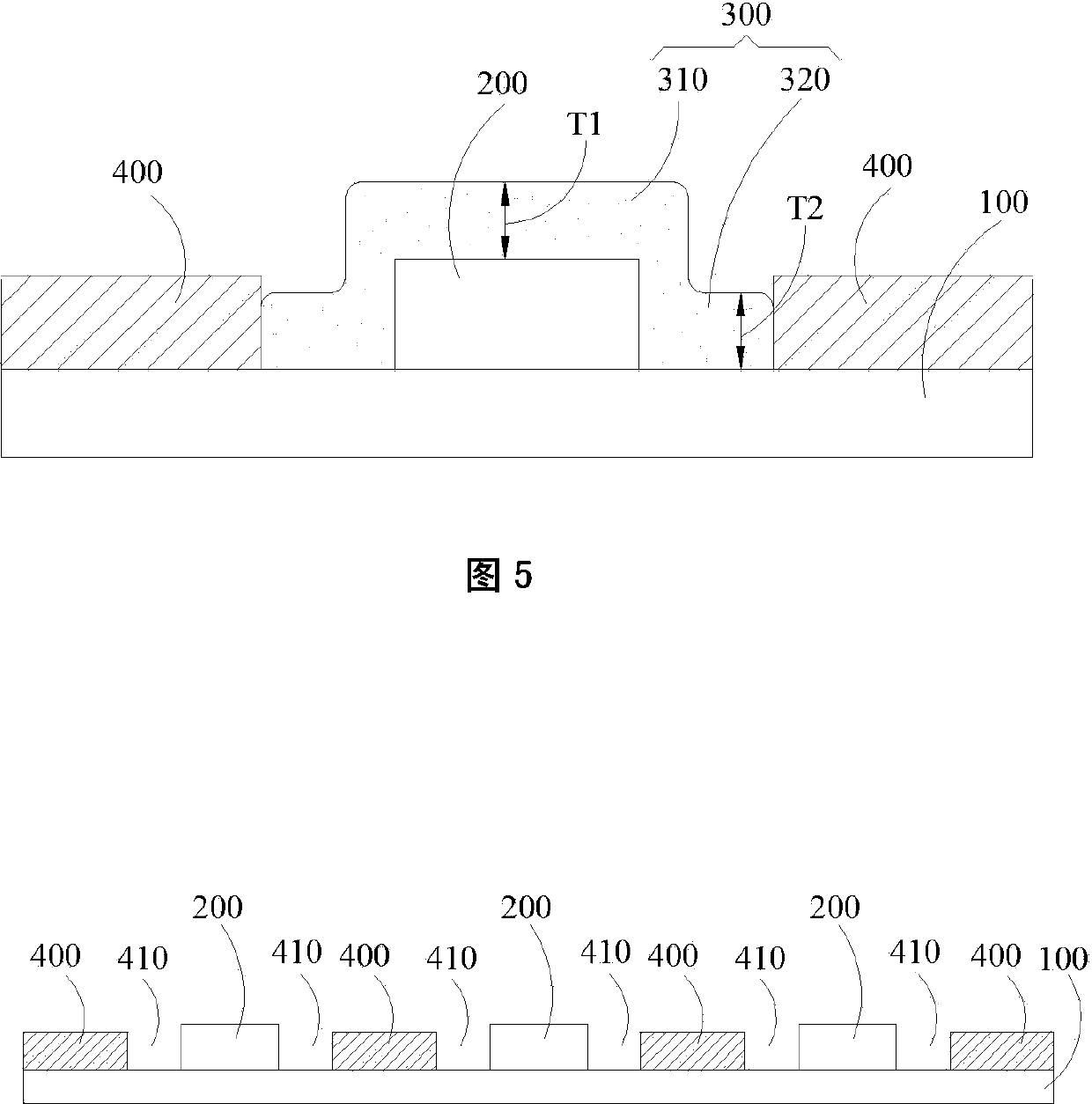

[0040] see image 3 , is a schematic diagram of the light-emitting device of the present invention. The present invention is a light emitting device, the light emitting device is a flat light emitting device, which includes: a substrate 100 , a light emitting diode chip 200 is arranged on the substrate 100 , and a phosphor layer 300 covers the light emitting diode chip 200 . Wherein the phosphor layer 300 has a first covering portion 310 and a second covering portion 320, the first covering portion 310 covers the top surface of the light emitting diode chip 200, the second covering portion 320 is located at the periphery of the light emitting diode chip 200 The top surface of the second cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com