Improved motor structure

A motor and casing technology, which is applied in the field of thin flat linear vibration motors, can solve the problems of vibration unit hitting the casing, elastic failure, and inability to use, so as to increase the frequency of vibration use, prolong the service life, and enhance the impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further detailed below in conjunction with the accompanying drawings:

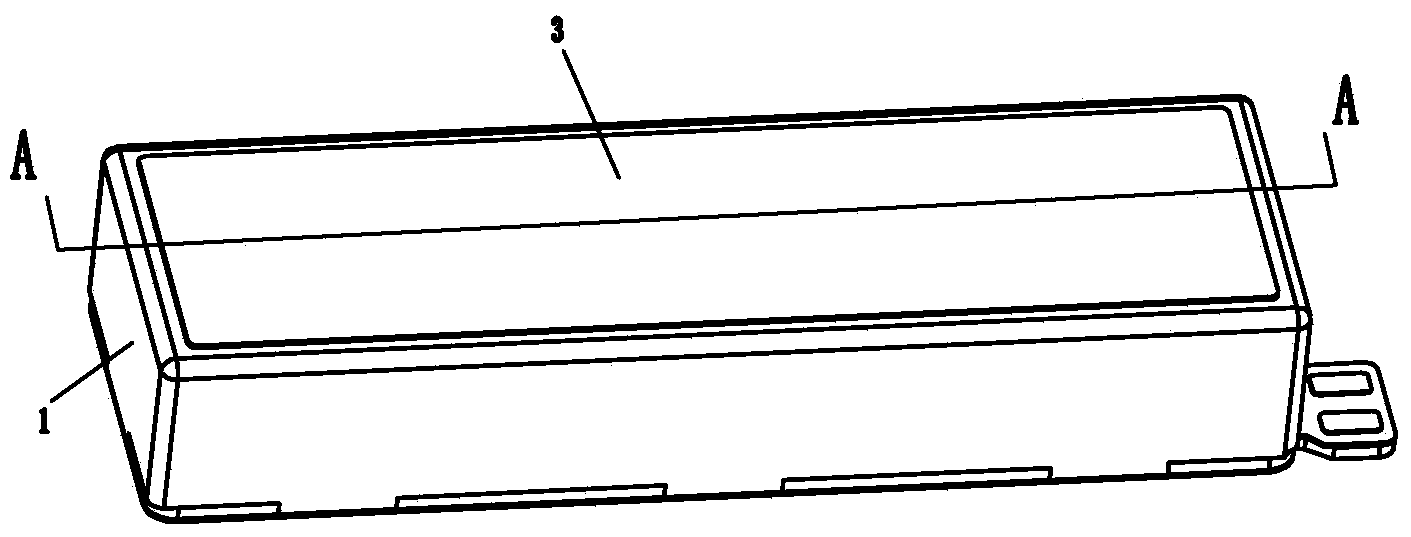

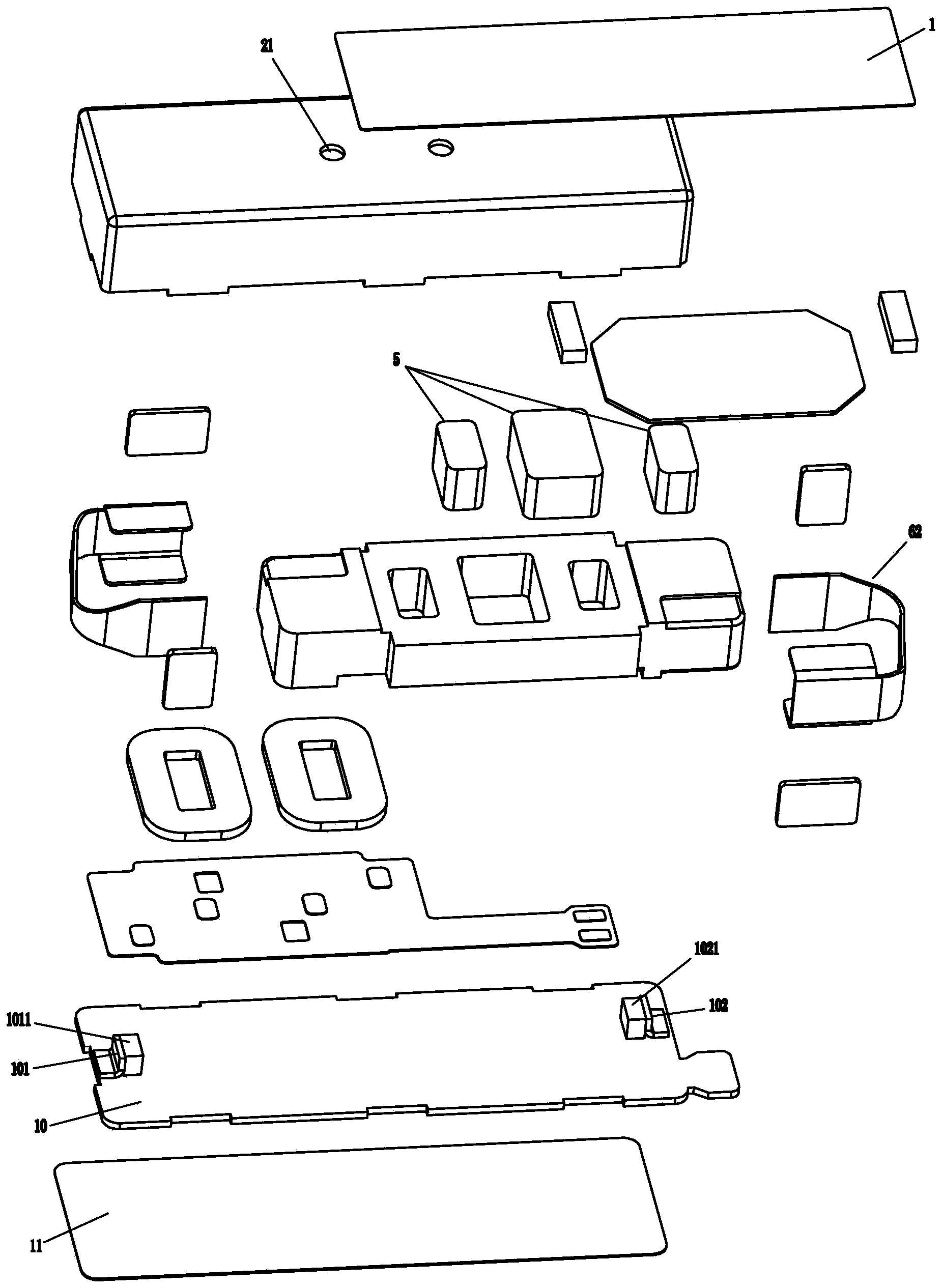

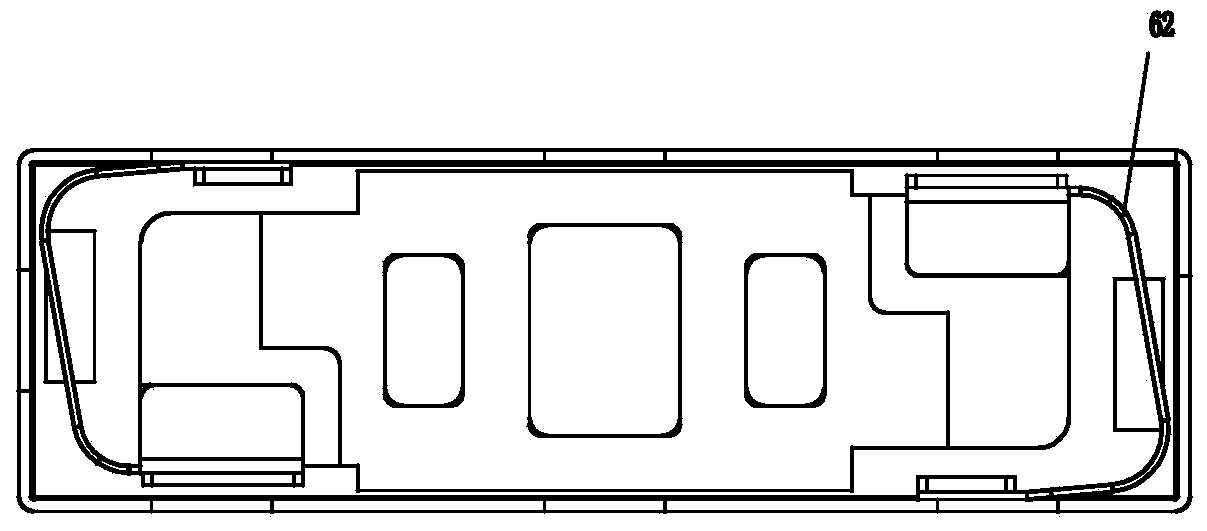

[0018] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown are examples of the improved structure of the motor of the present invention. It includes a casing 2, a base 10, and a vibration unit. The vibration unit includes an elastic support 62. The vibration support 62 is a one-piece elastic sheet. The shape of the elastic sheet is like a "U" shape. Each bend has a gentle arc and a larger radius of curvature. The use of a one-piece large-rotation elastic sheet used in a small space has changed the usual design thinking of the technicians, and can fully release and exert the resistance and elasticity of the elastic sheet, its impact resistance is greatly enhanced, and the number of vibration uses is large Improve, effectively extend the service life of the motor.

[0019] In an embodiment of the improved structure of the motor of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com