Protective glove

A technology of protective gloves and gloves, applied in protective clothing and other directions, can solve the problems of airtightness, inability to weave the tightness and fastness of leather, and affecting the normal use of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The protective gloves of the present invention will be described in detail below in conjunction with the accompanying drawings.

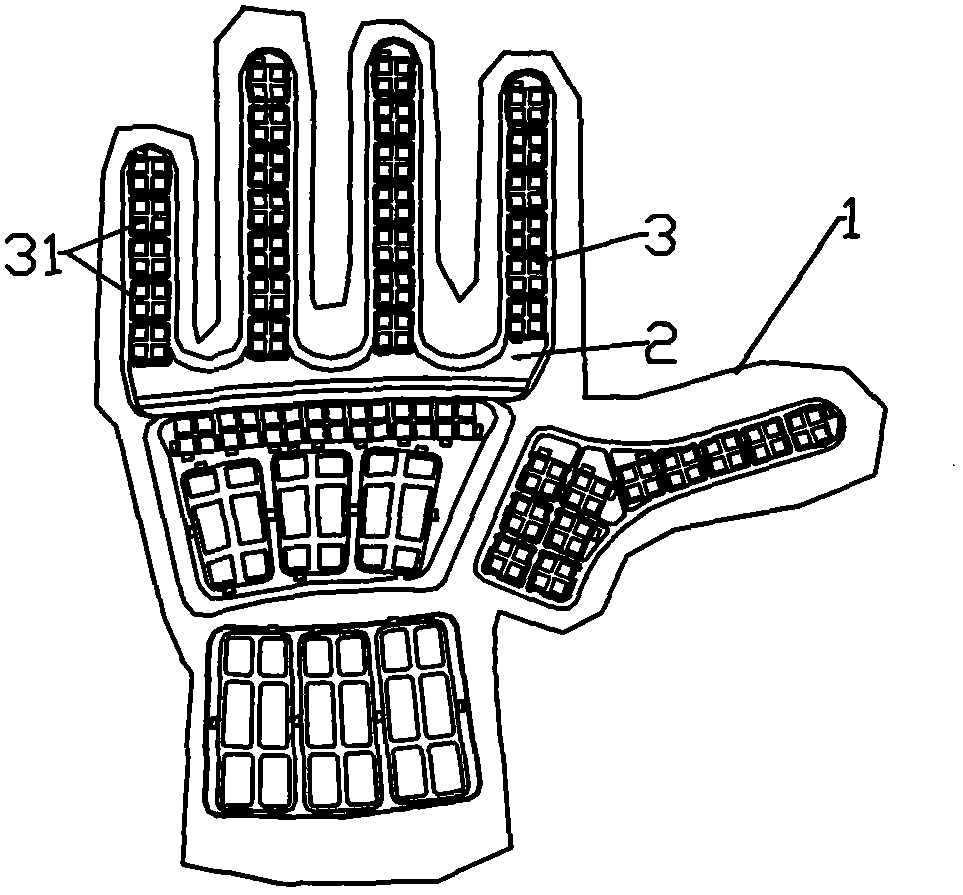

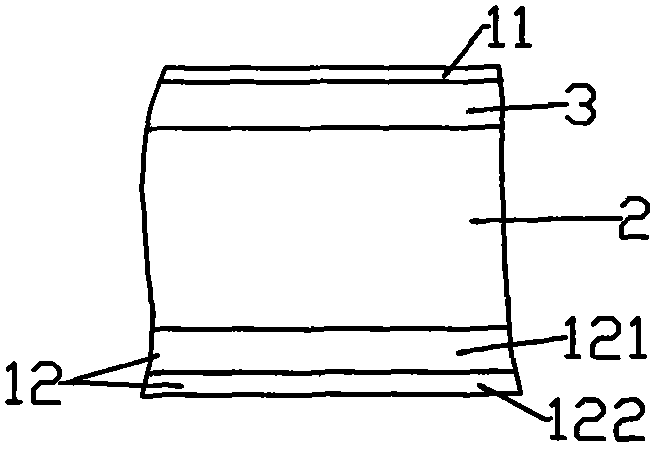

[0016] like figure 1 , figure 2 The protective glove of the present invention comprises a glove body 1, an elastic carrier 2 capable of maintaining elasticity in the temperature range of minus 60 degrees to minus 150 degrees is arranged in the wall of the glove body, and the surface layer of the elastic carrier 2 is embedded or covered There is a layer of hard material surface body 3 . Among them, the elastic carrier 2 and the hard material surface body 3 are mainly located at the place where the glove contacts the back of the hands and the forearm, that is, the back of the glove and the forearm of the glove, and the hard material surface 3 is segmented into small components, which are then combined to form become. The glove cavity is formed by the walls of the glove body. The wall of the glove body 1 is a double-walled structure compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com