An intelligent mobile working robot

A technology of robots and mobile mechanisms, applied in the field of robots of materials, can solve the problems that robots cannot meet the actual work requirements, and achieve the effect of saving manpower, great flexibility and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

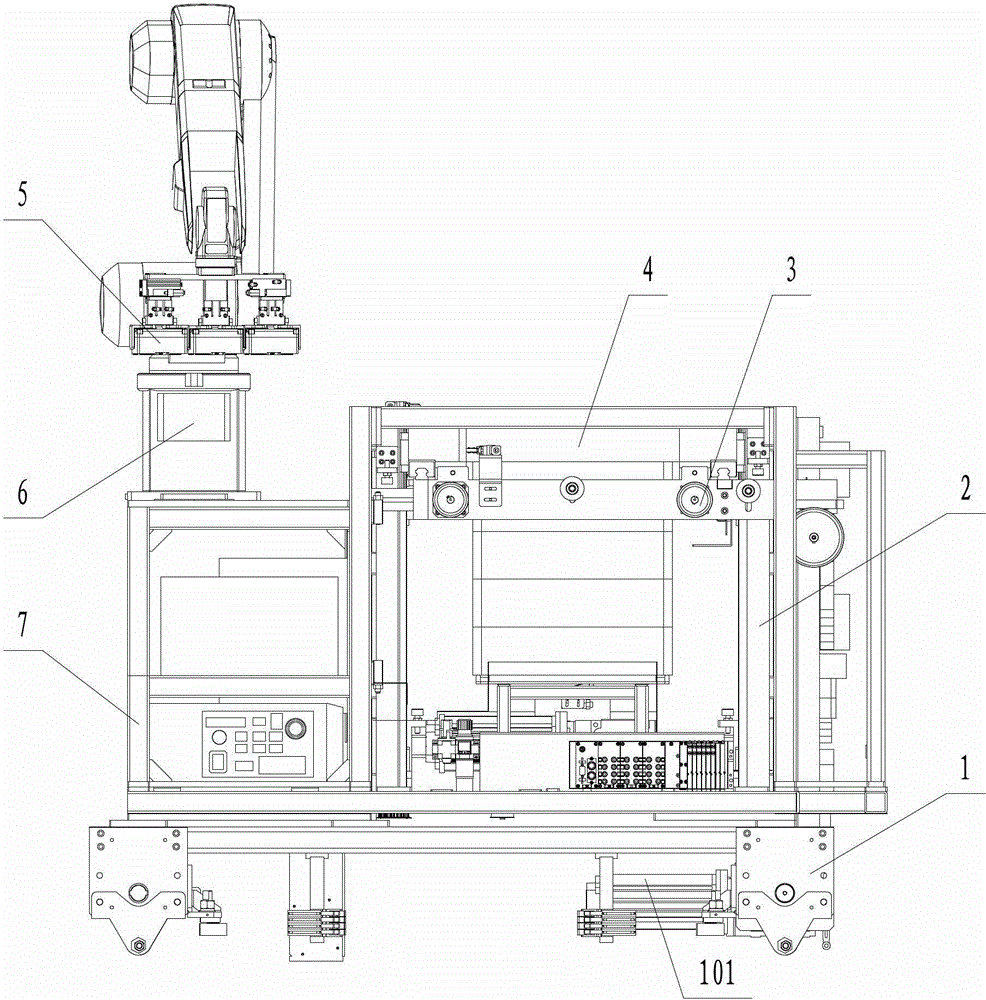

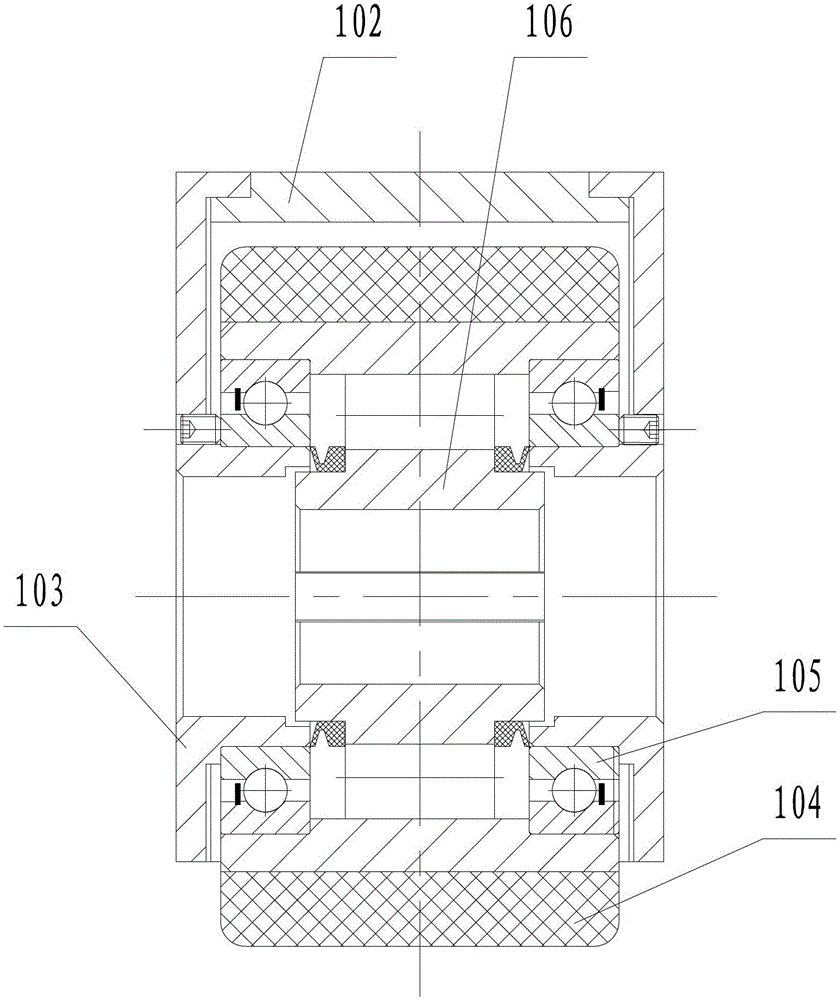

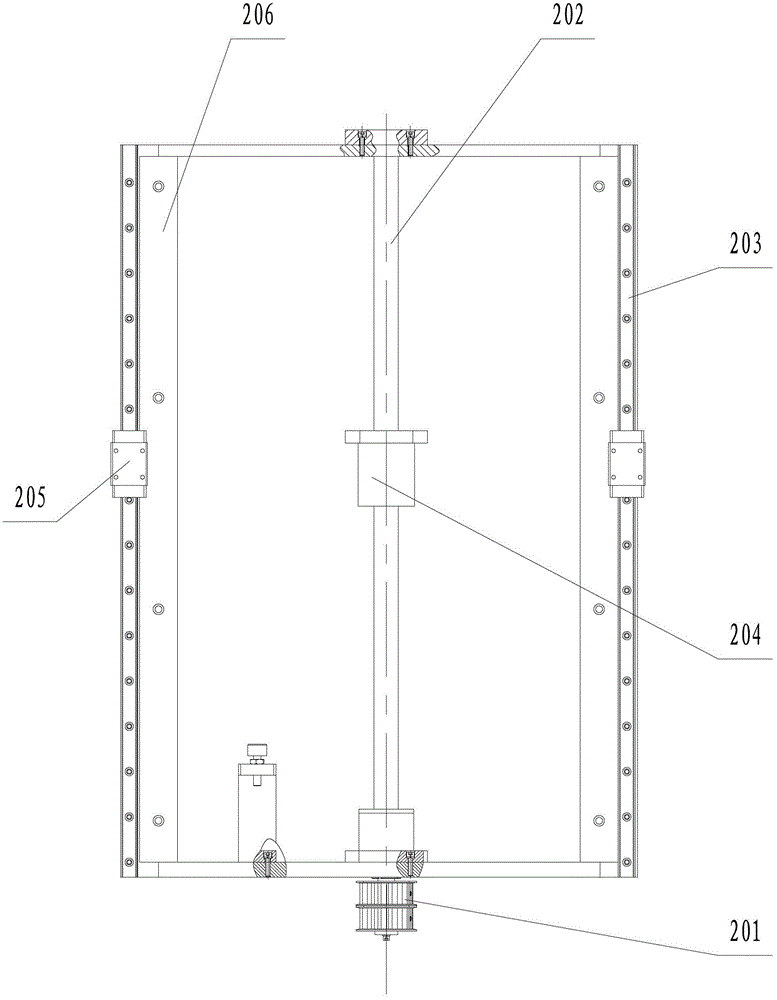

[0026] The intelligent mobile working robot of the present invention can move automatically, and can automatically take, store and deliver materials, and the automatic loading and unloading of materials does not require manual intervention. Such as figure 1 As shown, the present invention includes a moving mechanism 1, a fork lifting mechanism 2, a fork feeding mechanism 3, a fork clamping mechanism 4, a grabbing mechanism 5, a multi-axis linkage robot 6 and a frame body 7, wherein the moving mechanism 1 is installed On the frame body 7, the frame body 7 is driven to walk, the fork lifting mechanism 2 and the multi-axis linkage robot 6 are respectively installed on the frame body 7, and the output end of the multi-axis linkage robot 6 is connected with a grasping mechanism 5, and the fork lifting mechanism 2. The fork feeding mechanism 3 and the fork clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com