Automatic tape attaching device and method

A driving device and tape technology, applied in lamination devices, chemical instruments and methods, transportation and packaging, etc., can solve the problems of low practicability, narrow application scope, and inability to achieve full automation, and achieve improved processing yield, The effect of improving work efficiency and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

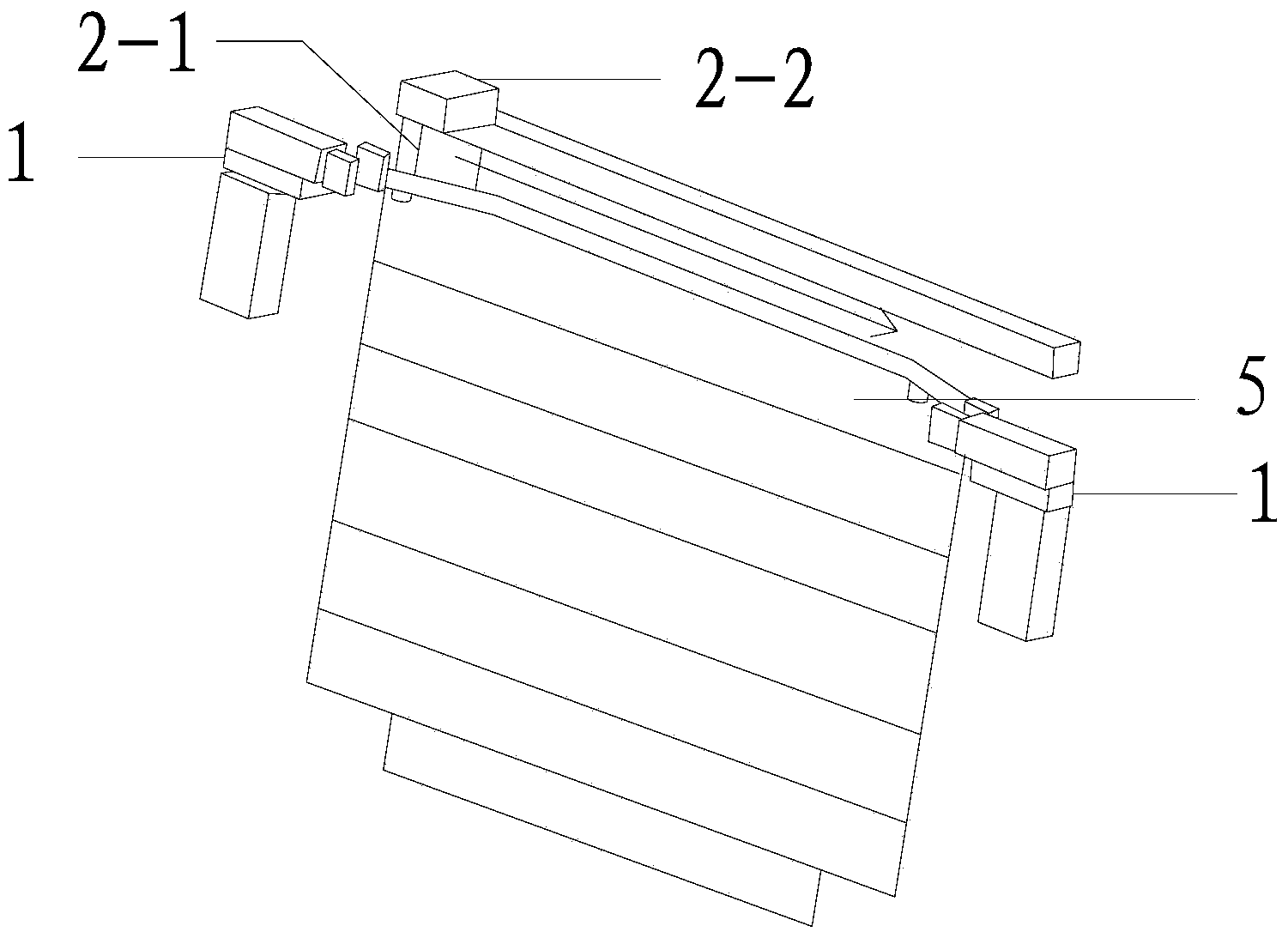

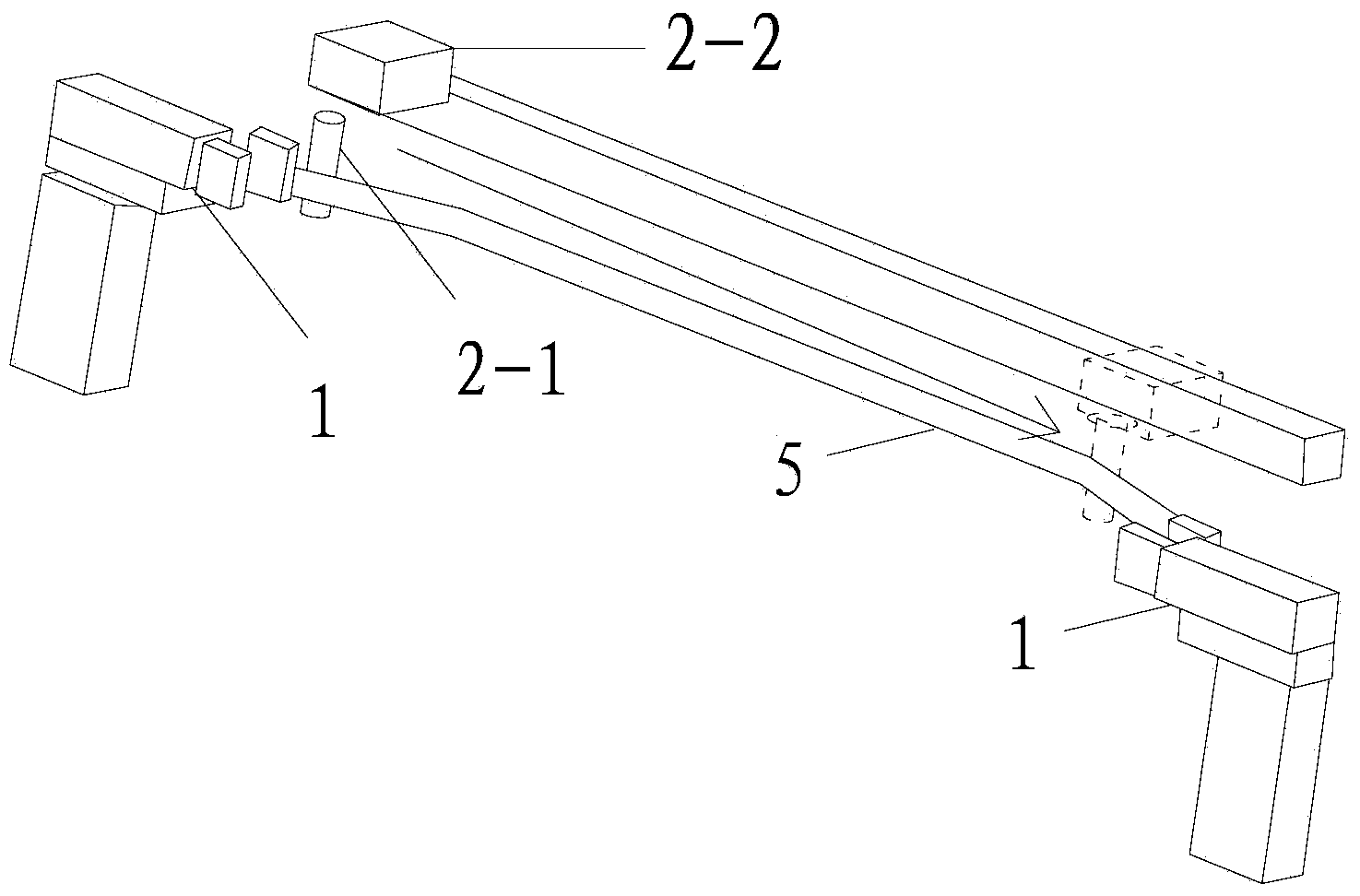

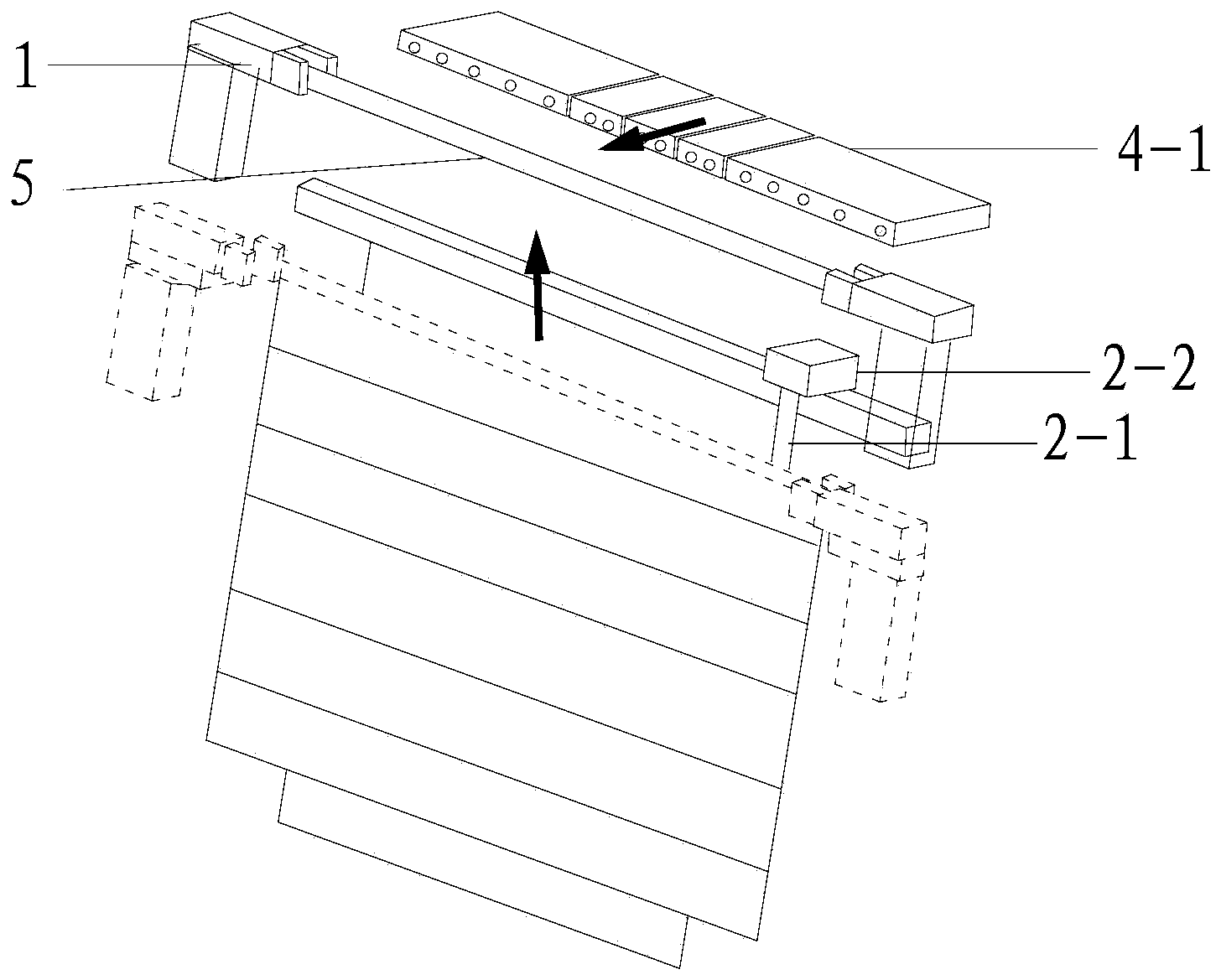

[0077] The tape automatic attaching device described in this embodiment includes three groups of subunits, and each group of subunits includes a tape clamping cylinder 1, a tape stripping mechanism, and a tape absorbing / attaching mechanism.

[0078] like figure 1 and figure 2 As shown, the adhesive tape clamping cylinder 1 fixes the adhesive tape 5, and the adhesive tape peeling mechanism is located at any starting end of the adhesive tape 5; constitute. Adhesive tape folder clamps a corner of adhesive tape 5, and adhesive tape stripping cylinder 2-2 drives stripping bar 2-1 to move from the starting end of adhesive tape to the end, completes adhesive tape stripping.

[0079] Since the four sides of the light guide plate 6 in this embodiment except the light-incident side, the rear side is a regular surface, and the left and right sides are irregular surfaces, therefore, in this embodiment, the subunits corresponding to the irregular left and right sides of the light guide ...

Embodiment 2

[0082] Compared with Embodiment 1, the difference lies in that the three sides of the light guide plate 6 in this embodiment are irregular, and among the three groups of subunits of the automatic tape sticking device, each group of subunits includes a tape clamping cylinder, Tape peeling mechanism, tape cutting mechanism and tape adsorption / attachment mechanism.

Embodiment 3

[0084] Compared with Example 1, the difference is only that, as Figure 4 As shown, the tape cutting mechanism described in this embodiment is a single-blade cutting mechanism, including a slidable blade 3-1, a blade control cylinder 3-2 and a blade positioning shaft for driving and supporting the sliding of the blade 3-1 3-3. During the use of the single-blade cutting mechanism, the slidable blade 3-1 is driven by the blade control cylinder 3-2 to slide along the blade positioning shaft 3-3, and automatically cuts the tapes sequentially at designated positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com