Overhaul column of electrified railway catenary

An electrified railway and catenary technology, applied in railway car body parts, transport passenger cars, transportation and packaging, etc., to achieve the effect of improving operation accuracy and working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

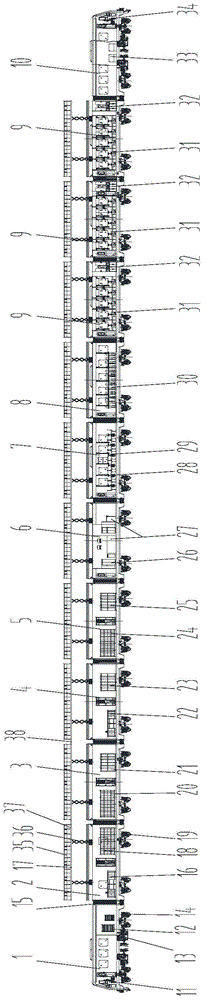

[0019] Attached below figure 1 An embodiment of the present invention is described.

[0020] The electrified railway catenary maintenance column is composed of tractor I1, multiple operating vehicles and tractor II10, the operating vehicles are placed between tractor I1 and tractor II10 and tractor I1, multiple operating vehicles and tractor II10 All are connected by folding windshields 15, and the tops of the multiple work vehicles are provided with elevating work platforms 17, and the elevating work platforms 17 are connected to each other after they are raised. Specifically, the elevating work platforms 17 include folding railings 35, The lifting mechanism 36 and the working platform 37, one end of the lifting mechanism 36 is connected to the top of the work vehicle, the other end of the lifting mechanism 36 is supported on the bottom of the working platform 37 and the lifting mechanism 36 is provided with a position sensor to ensure that a plurality of working platforms 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com