Center shaft torque sensing device of electric bicycle

An electric bicycle and sensing device technology, which is applied in vehicle components, rider drive, transportation and packaging, etc., can solve the problem of difficult to ensure the contact stability between the contact piece and the slip ring, affecting the stability of the torque sensing signal, etc. The slip ring is easy to be scratched and other problems, so as to achieve the effect of low pressure, low friction loss and stable signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to allow people to understand the technical content of the present invention more clearly and intuitively, the technical content of the present invention will be described in detail below using a central motor of an electric bicycle equipped with the central shaft torque sensing device of the present invention as a specific example:

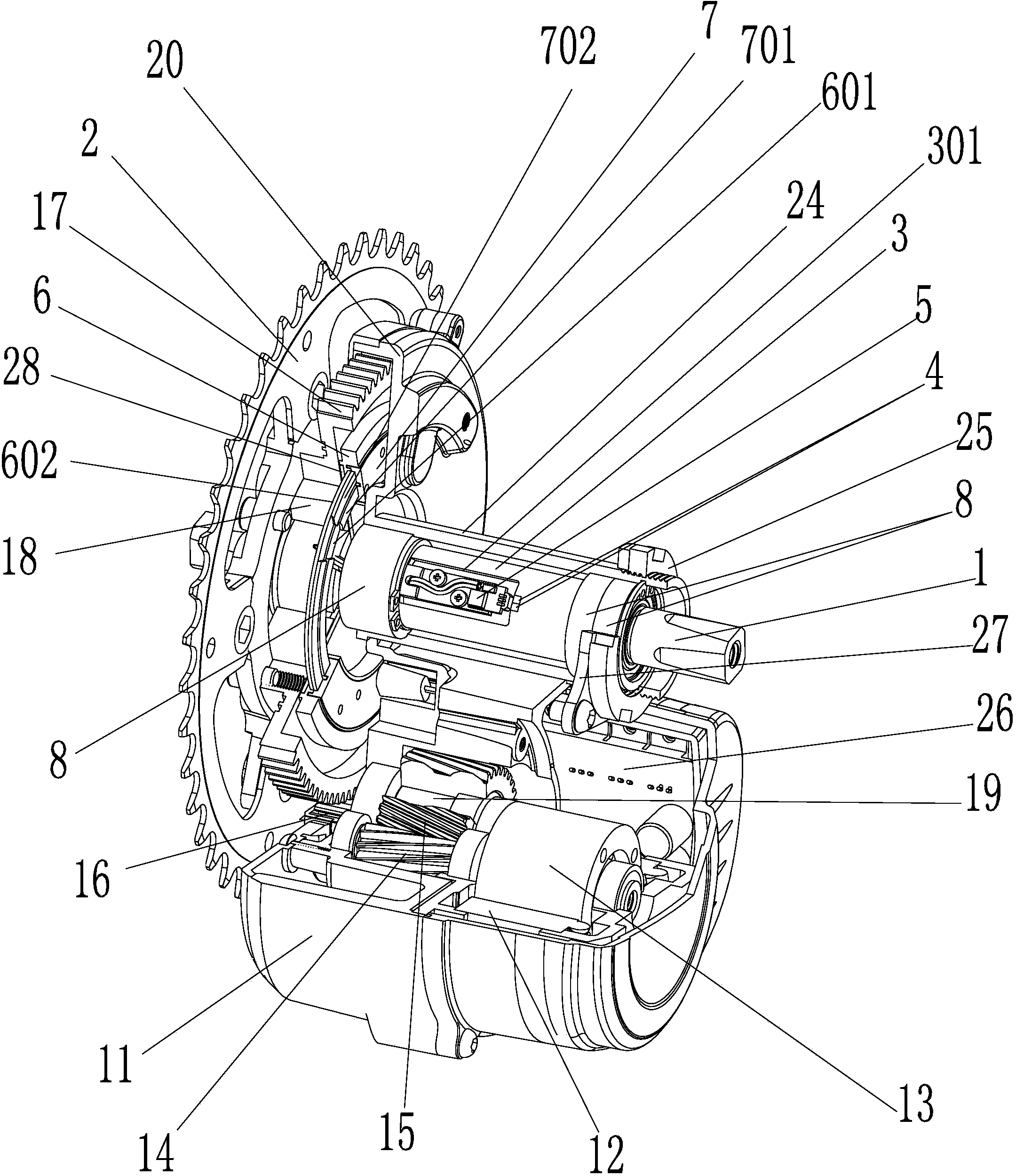

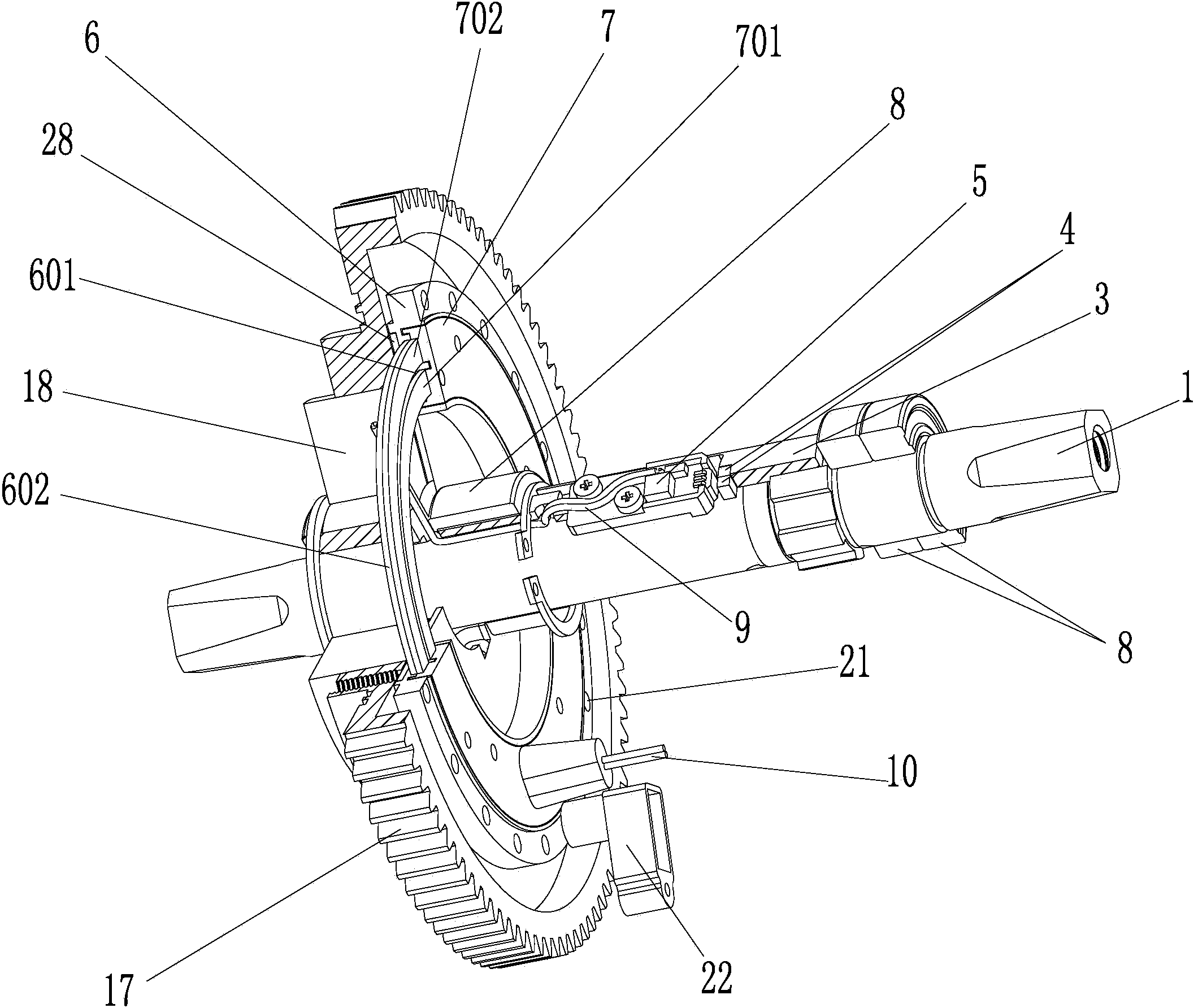

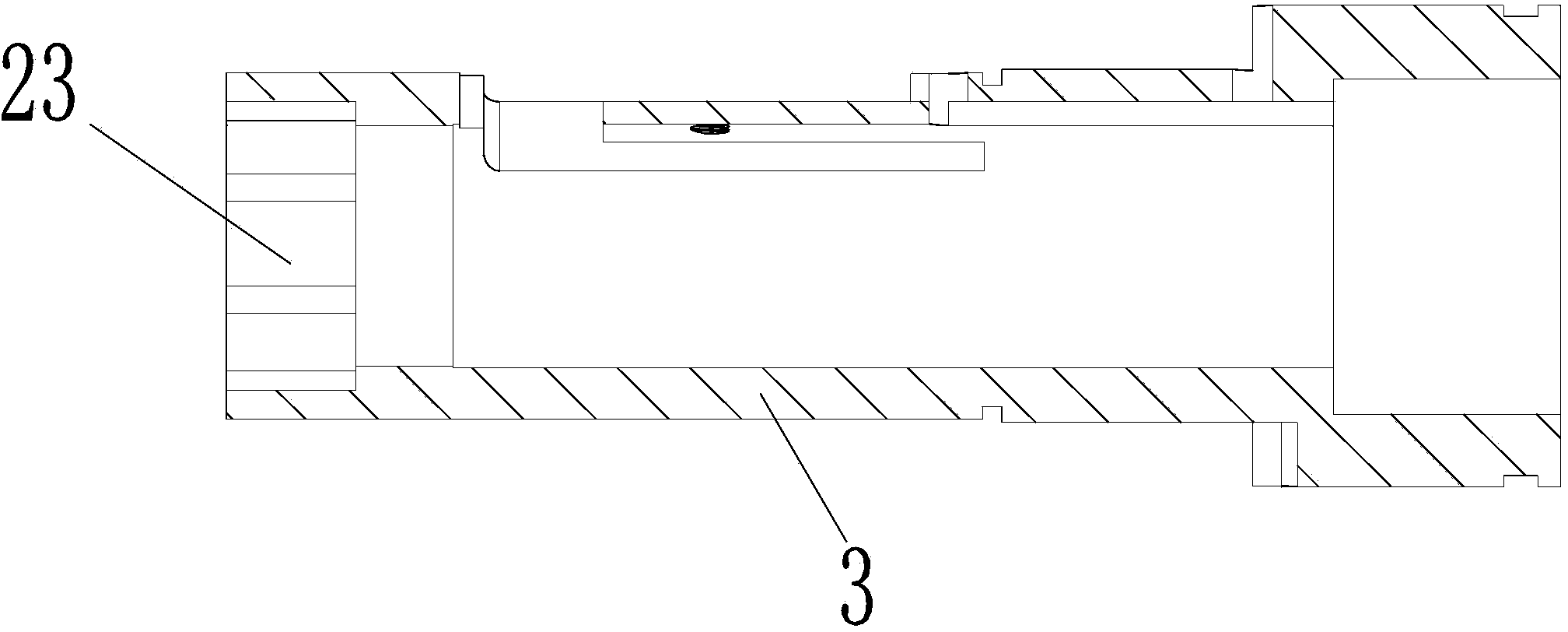

[0024] figure 1 and figure 2 It is a structural schematic diagram of the central motor of an electric bicycle adopting the bicycle center shaft torque sensor device of the present invention. The central motor includes a casing 11, a frame 20 and a motor connecting pipe 24, and the casing 11 and the frame 20 All are connected as a whole with motor connecting pipe 24. One end of the motor connecting pipe 24 is shaped on an external thread. When assembling, the motor connecting pipe 24 is pierced in the bicycle bottom bracket (not shown in the figure), and the threaded end of the motor connecting pipe 24 is stretched out of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com