Bag threading device

A packaging bag and belt threading technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problem of not being able to automatically arrange multiple packaging bags in sequence and string them into packaging bags to sort out and connect pieces, so as to adapt to large-scale industrialization The effect of high production and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

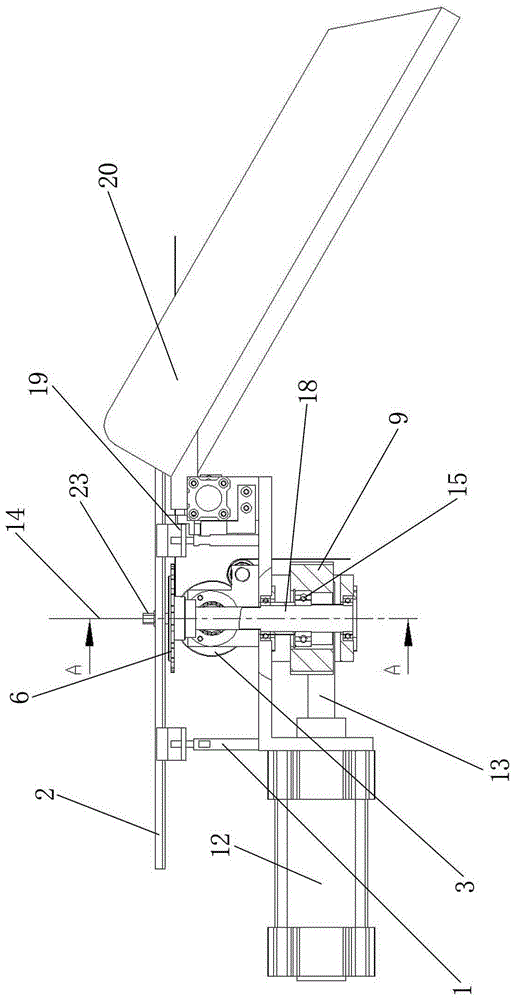

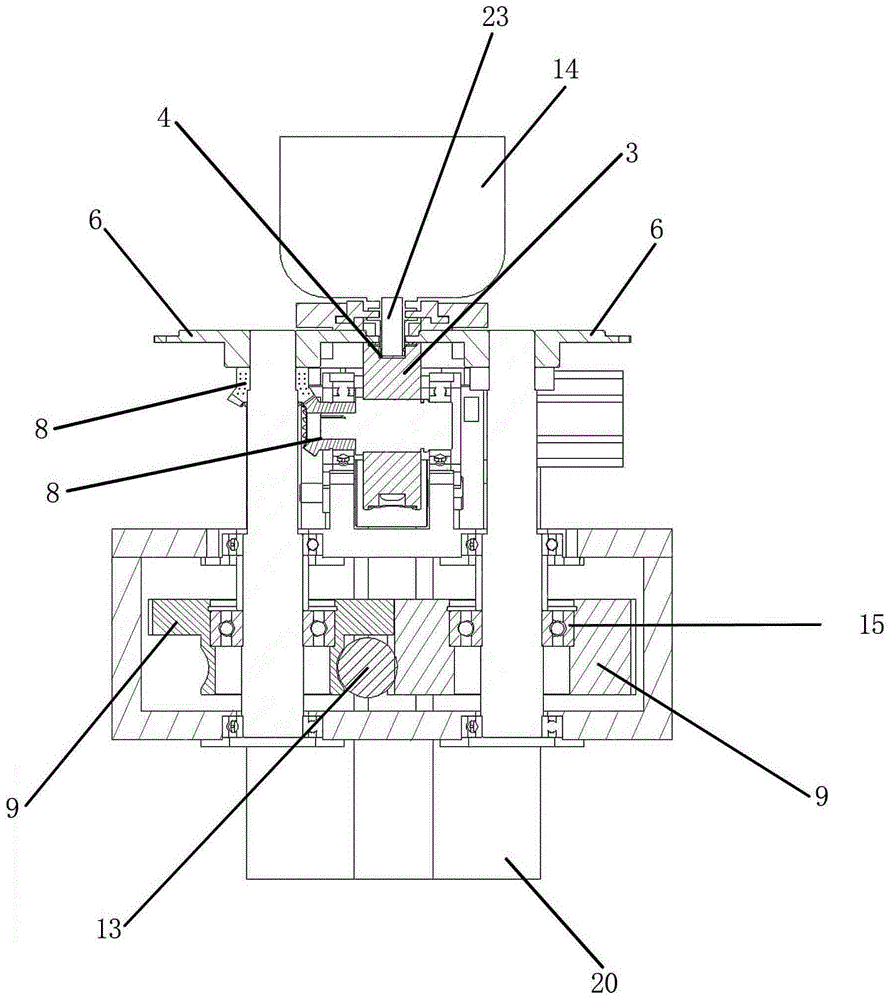

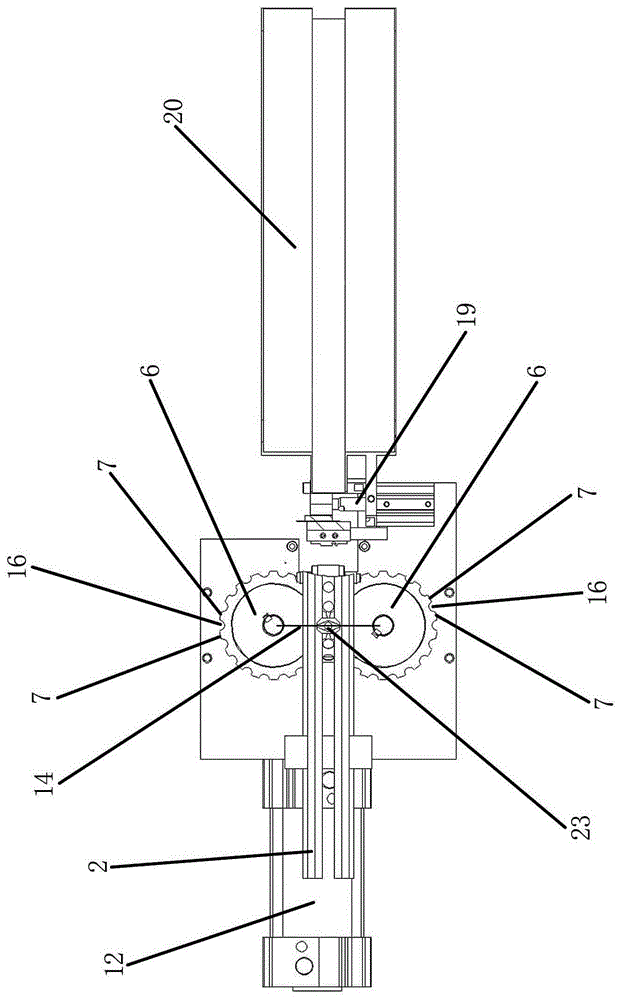

[0030] Such as Figure 1-3 As shown, the packaging bag threading device in this embodiment includes a frame 1, which is provided with a filling and drinking pipe positioning chute 2, a serial piece transmission mechanism, a pinch and pressure pipe mechanism, a driving mechanism, Cut-off mechanism 19 and collection chute 20.

[0031]The above-mentioned pinching and pressing mechanism is located below the positioning chute 2 of the filling and drinking pipe, and the above-mentioned serial piece transfer mechanism is located under the pinching and pressing mechanism.

[0032] The above-mentioned serial sheet transmission mechanism includes a positioning transmission roller 3, and the above-mentioned positioning transmission roller 3 is erected and rotatably installed on the frame 1 through the first rotating shaft 17, and the rotating shaft of the positioning transmission roller 3 is aligned with the positioning slide of the filling drinking pipe. The groove 2 is vertical; the c...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is:

[0044] The above-mentioned driving device is a motor, and a transmission gear 9 of the above-mentioned transmission mechanism is installed on the output shaft of the motor.

Embodiment 3

[0046] The difference between this embodiment and embodiment 1 is:

[0047] The above-mentioned driving mechanism adopts two driving devices to respectively drive the serial sheet conveying mechanism and the pinching and pressing tube mechanism to rotate.

[0048] The above-mentioned driving device is a motor. Above-mentioned motor can adopt servo motor or stepper motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com