Patents

Literature

35results about How to "Adapt to the needs of large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

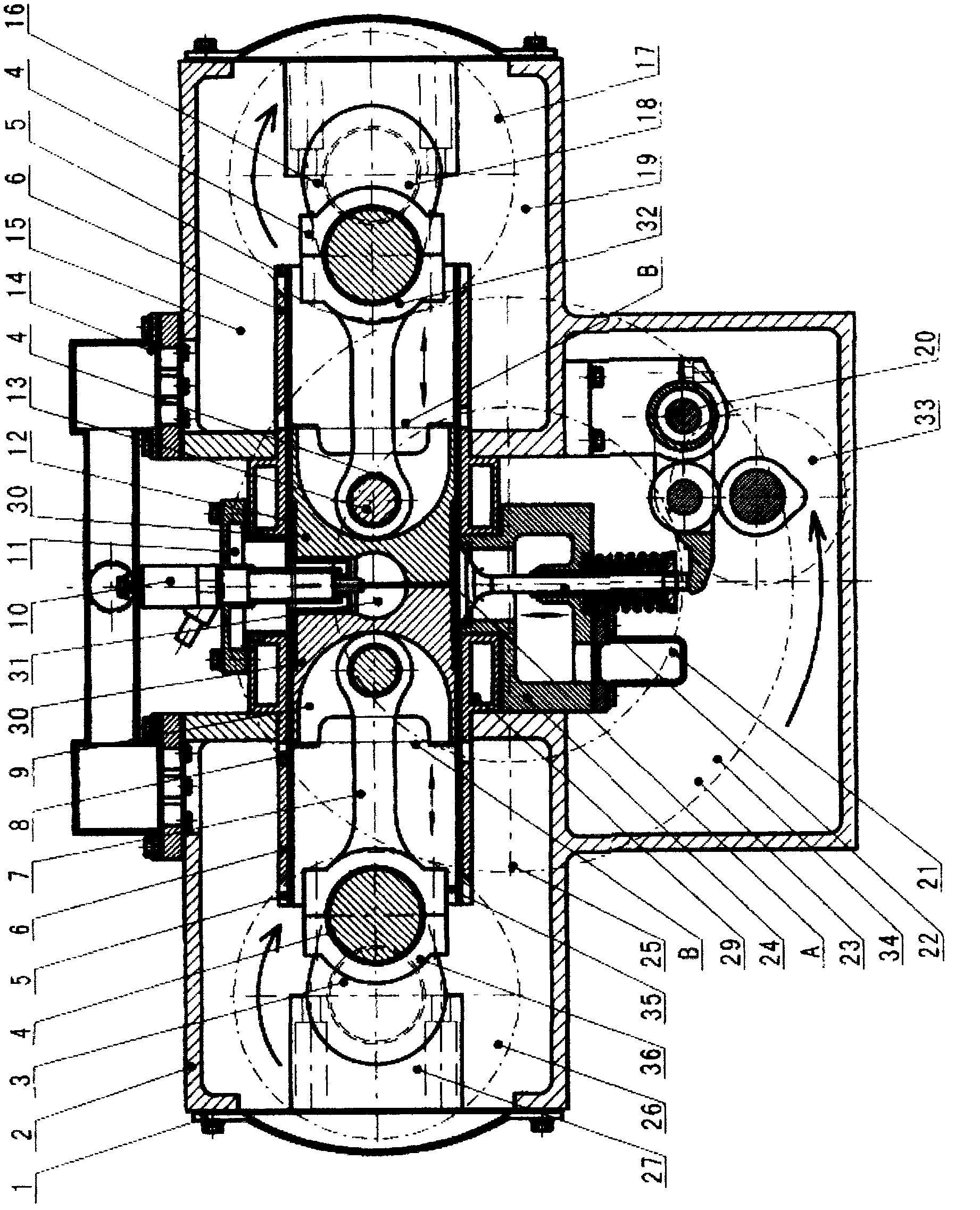

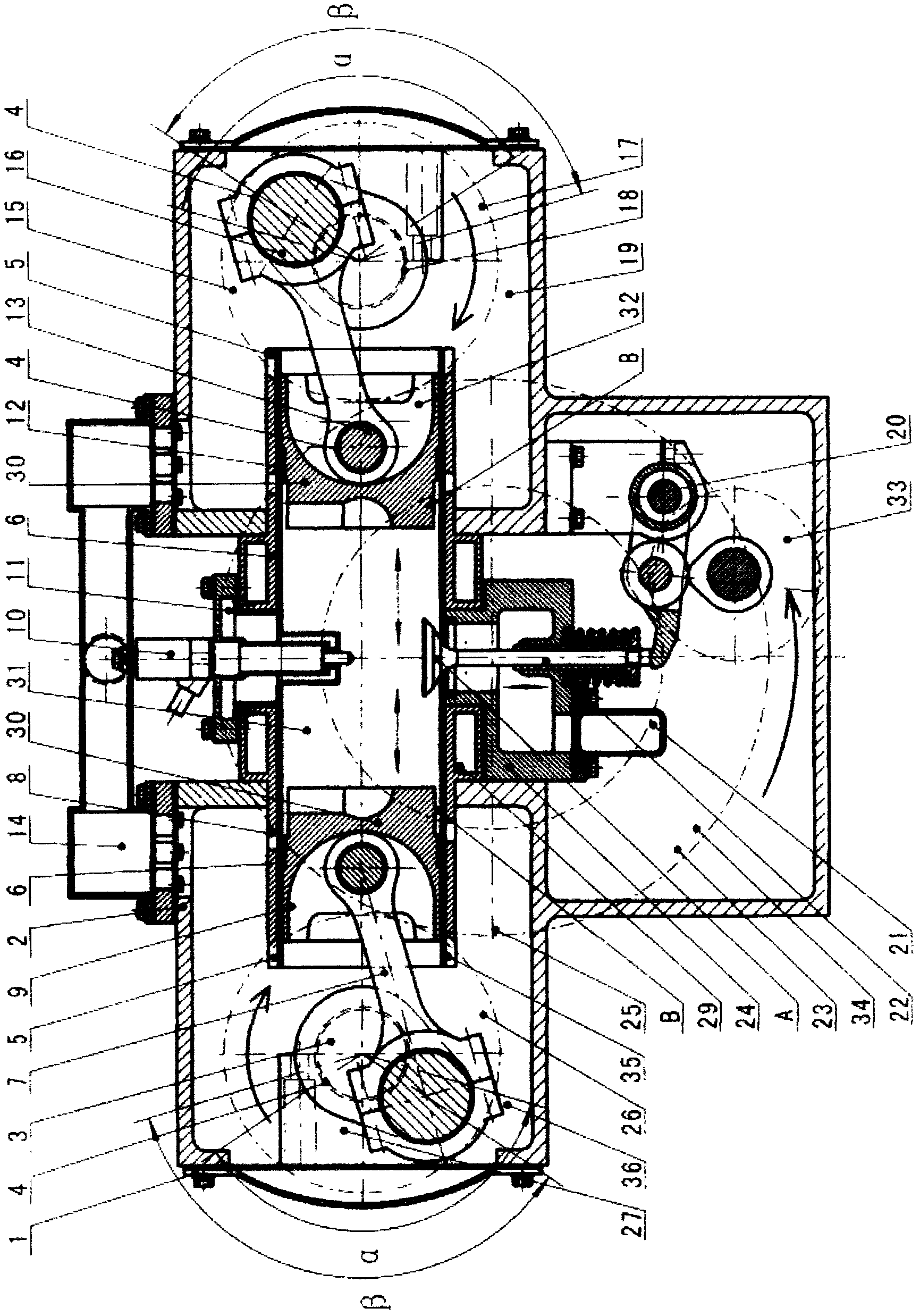

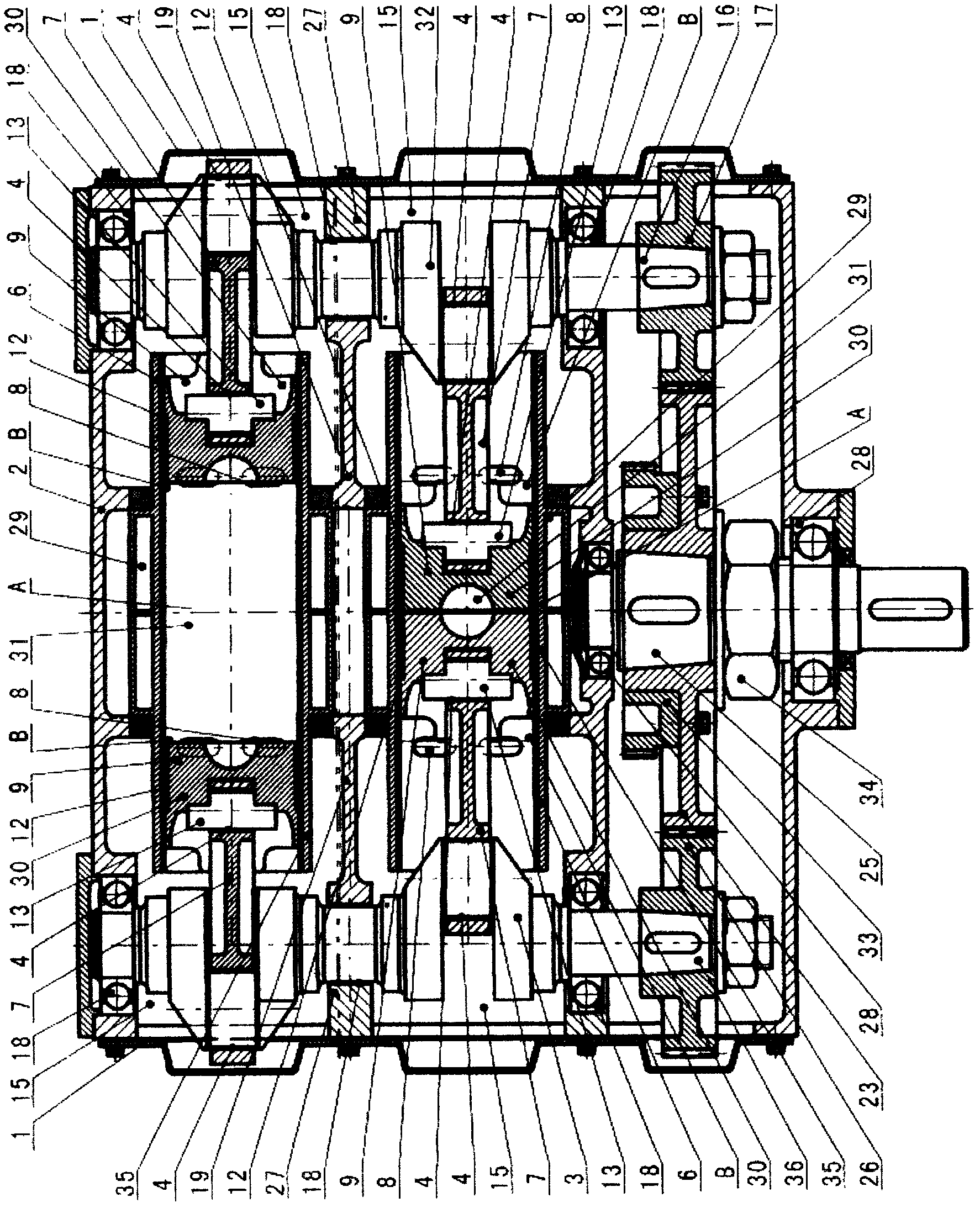

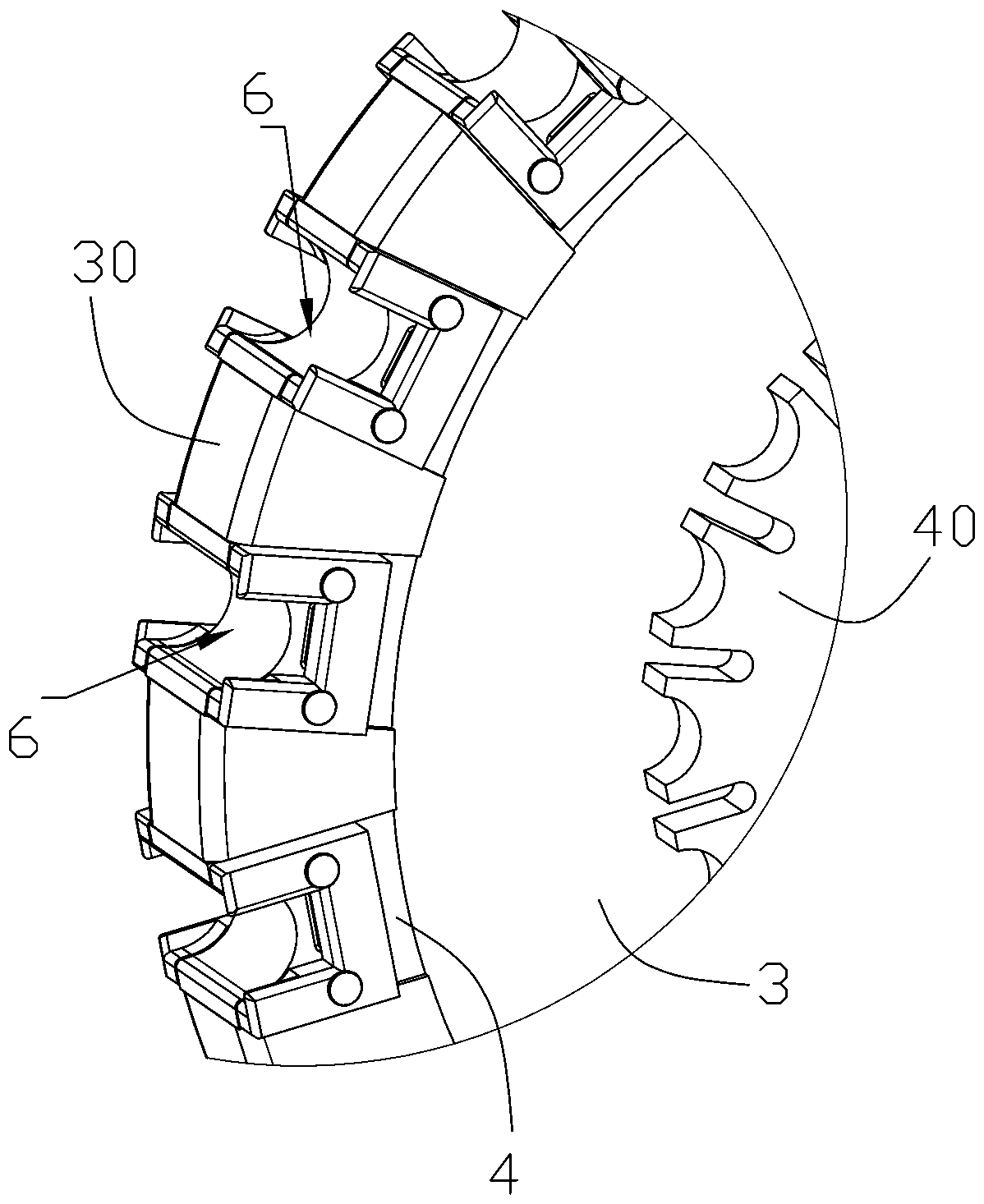

Two-stroke opposed-piston diesel engine

InactiveCN102644508AImprove energy conversion efficiencyExhaust completelyCylinder headsCylindersPistonFuel oil

The invention relates to a two-stroke opposed-piston diesel engine. The existing piston-type engine structure is that a piston is arranged inside an engine cylinder, the piston is connected with a crankshaft through a connecting rod to form a crankshaft linkage mechanism, and the energy conversion efficiency is only 25 to 35 percent. The invention aims at designing a two-stroke opposed-piston diesel engine. The two-stroke opposed-piston diesel engine structurally consists of piston mechanisms (3), a power output mechanism (34), a left crankshaft linkage mechanism (36), and a right crankshaft linkage mechanism (32), wherein the piston mechanisms (3) with the same structure and capable of synchronously moving in opposite directions are oppositely arranged at two sides inside an air cylinder barrel (6) of an air cylinder body (2), a burning chamber (31), a fuel oil nozzle mechanism (10) and a vent valve mechanism (22) are arranged on the middle position of the cylinder barrel (6). The two-stroke opposed-piston diesel engine has the advantages that by adopting a unique structure, two pistons are ingeniously and symmetrically arranged inside the cylinder barrel, so that multiple problems existing in the traditional piston-type engine can be high efficiently and reliably solved. The energy conversion efficiency can be improved.

Owner:李玉龙

Barium chloride production technology

InactiveCN101654274AReduce the number of devicesContinuous production processCalcium/strontium/barium chloridesChemistryBarium chloride

The invention discloses a technology for producing barium chloride by the witherite containing barium carbonate, which mainly comprises steps as follows: sulfur iron impurities are decomposed and oxidated to remove and the hydrated barium salt raw material liquid is prepared; the raw material liquid is electrically heated and concentrated in vacuum, which is driven by an axial flow pump, the solute is thermally crystallized to form the hydrated barium chloride dihydrate saturated crystalline; the crystallized hydrate is cooled to produce the serial barium salt products, wherein the vacuum heating condensation crystallization is a continuous production process; the whole technological process is implemented in the closed state; the by-products could be recycled; the crystallisation processis completed at one time and the production process is continuous. The products manufactured in the technological process has low impurity content, saves energy, is adaptive to the large-scale industrialization production and reduces the pollution and resource waste to a large extent.

Owner:重庆洋铭化工产品有限公司

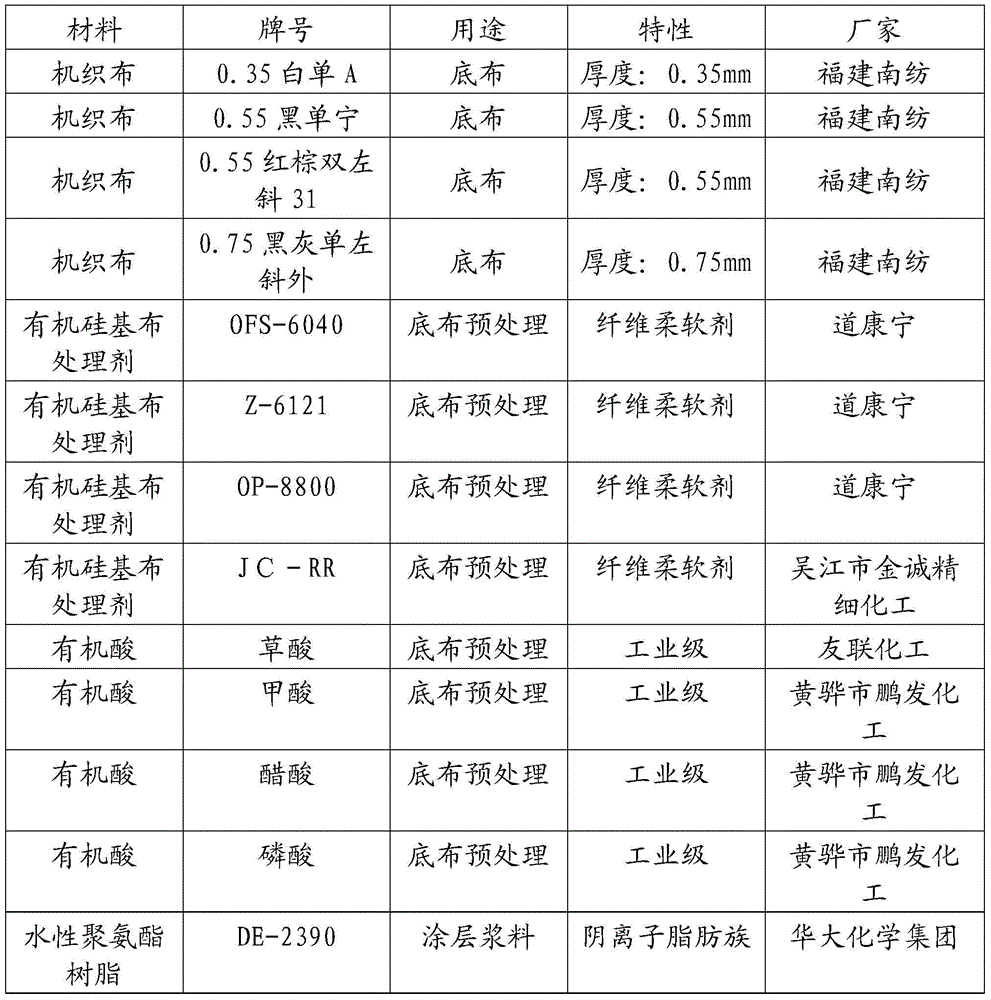

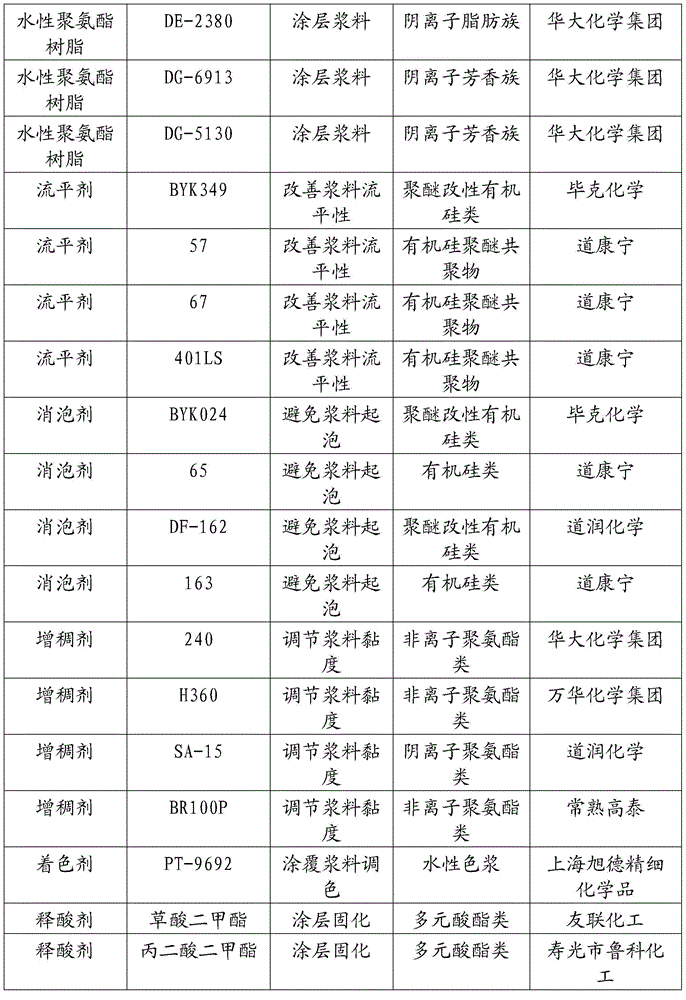

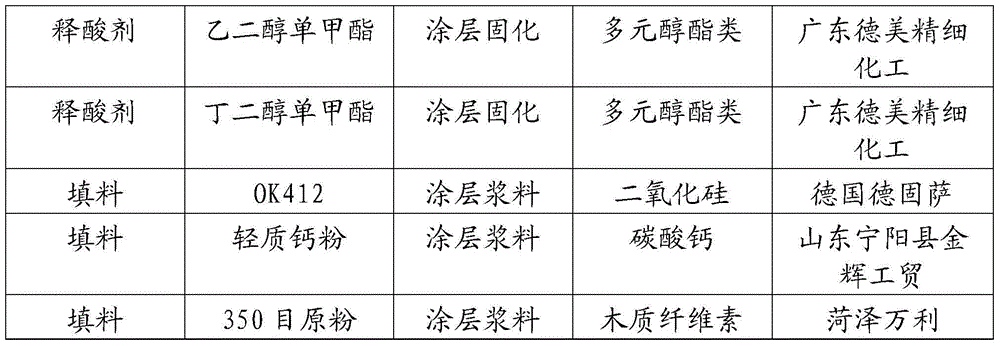

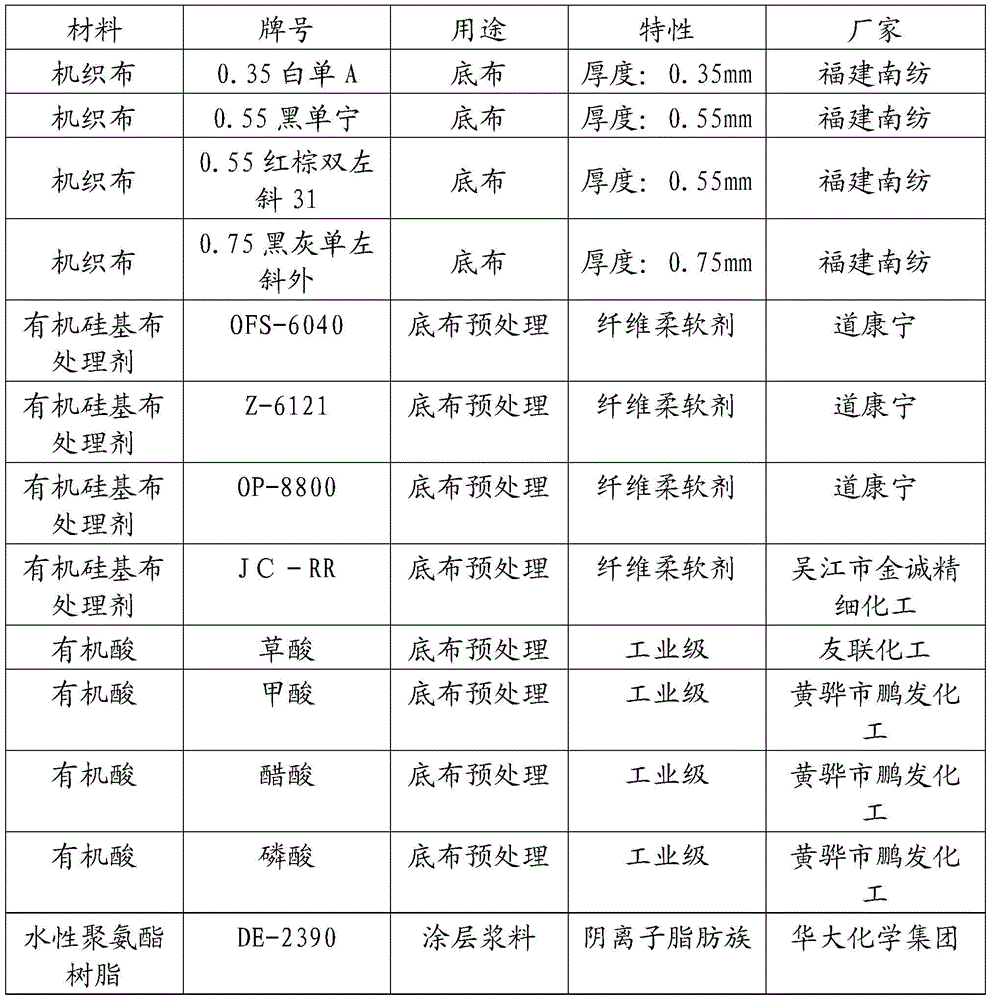

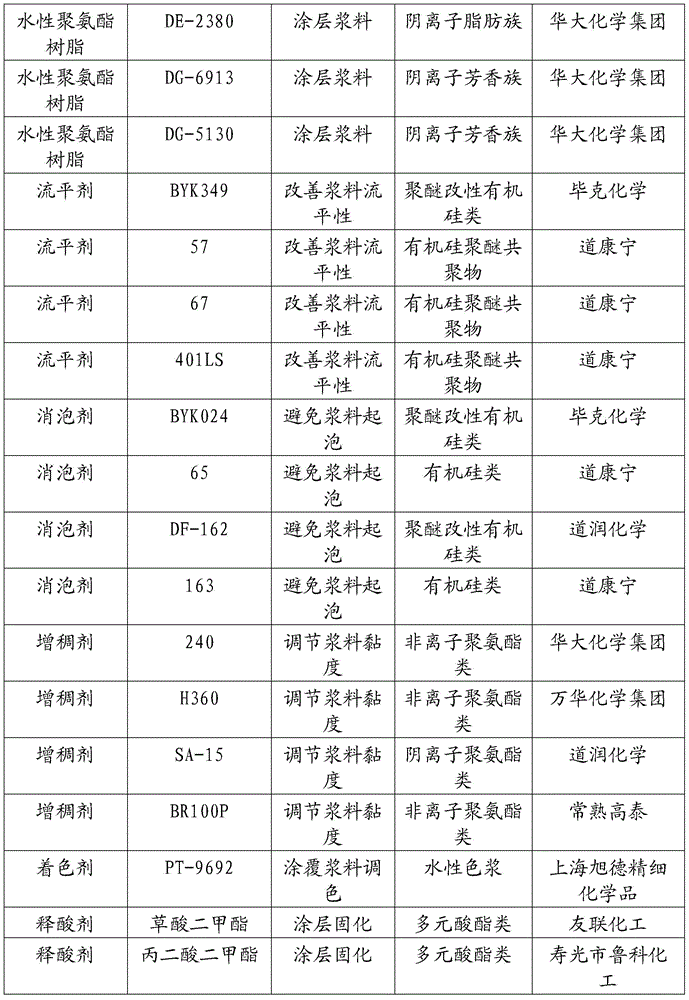

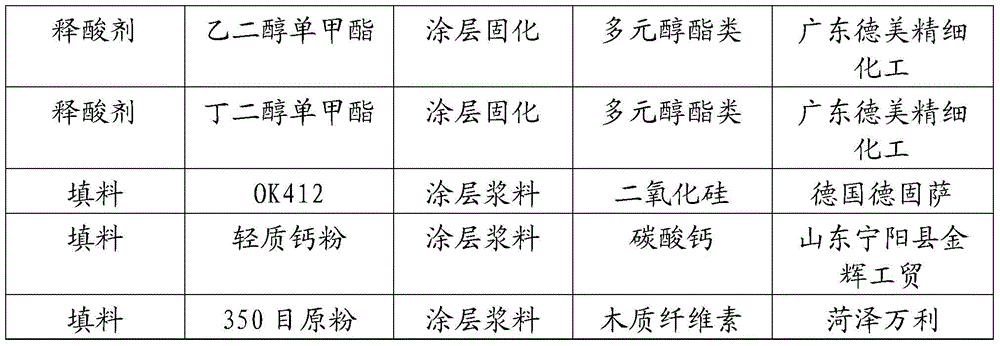

Method for producing water-based polyurethane synthetic leather

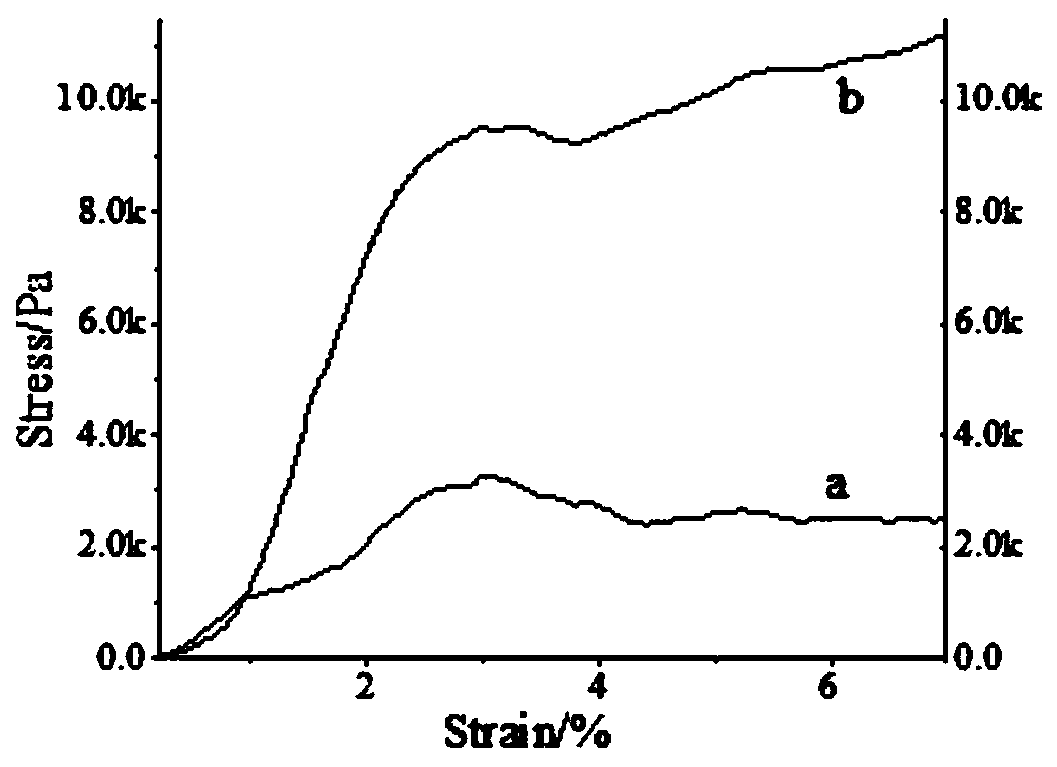

The invention relates to a method for manufacturing water-based polyurethane synthetic leather. The designed technological process comprises the steps of preparing base fabric, humidifying and arranging the base fabric, coating water-based sizing agent, acid-releasing, solidifying, forming, washing, drying and sizing. The method has the advantages that no solvent is added, the organic contamination is thoroughly eliminated from the source, the potential safety hazards are eliminated, the working environment of workers is improved, and green and environment protective cleaning production is achieved indeed; the performances of a product is close to or superior to those of a solvent type product in appearance, structure, hand feeling and physical property, and the product is the best substitute for the solvent type product as well as a mainstream product of synthetic leather field development in the future.

Owner:HUADA CHEM GRP CO LTD

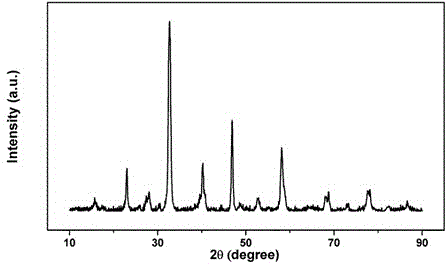

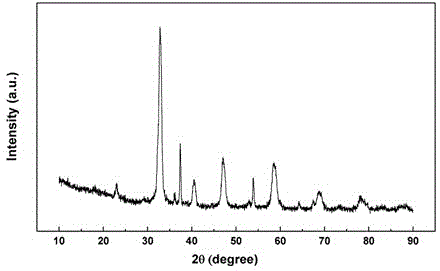

Low temperature preparation method of layered perovskite

InactiveCN104876275ALow preparation temperatureExpand the scope of applicationZirconium compoundsTitanium compoundsPerovskite (structure)Chloride

The invention discloses a low temperature preparation method of Ruddlesden-Popper type layered perovskite. By using ''chloride ion induction effect'', a uniform layered precursor containing the chloride ions is formed, then the chloride ions in the precursor are dissociated and removed, and thus the layered structure is obtained. Compared with a traditional R-P type layered perovskite preparation method, the method has the advantage that the preparation temperature in the method is greatly reduced, so that the application scope of the type of the materials is expanded. The obtained materials possess high performance in the aspects of specific surface, thermal stability, electromagnetic performance, catalytic activity and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

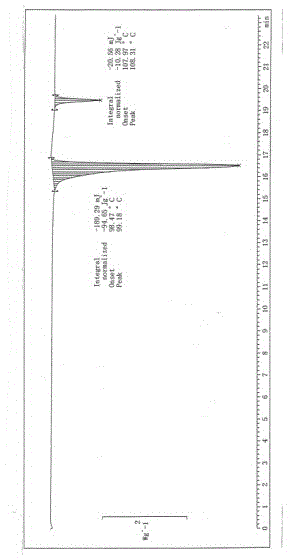

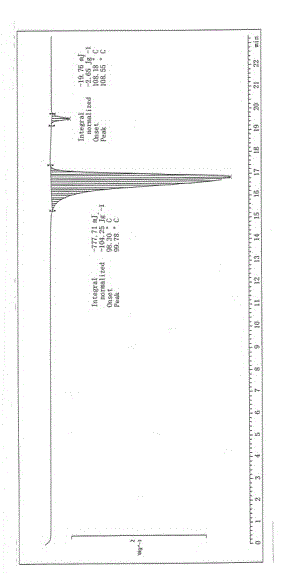

Medicinal composition for improving stability of crystal medicines, and preparation method thereof

InactiveCN104721828AStir wellNo changeOrganic non-active ingredientsPharmaceutical active ingredientsCelluloseActive component

The invention discloses a medicinal composition for improving the stability of crystal medicines, and a preparation method thereof. The medicinal composition is composed of a metastable crystal medicine, a protection agent and pharmaceutical adjuvant; and the protection agent is one or a mixture of more of polyvinylpyrrolidone, hydroxypropyl methyl cellulose, hydroxy propyl cellulose and polyethylene glycol. The preparation method mainly comprises the following steps: adding the protection agent into a solvent, stirring for dissolving until a clear state, adding the metastable crystal medicine, and uniformly stirring to obtain a metastable crystal medicine containing the protection agent; and adding the pharmaceutical adjuvant according to a certain proportion, uniformly mixing to prepare particles, drying, and granulating to obtain active component-containing uniform particles. The preparation method can maximally maintain the metastable crystal medicine unchanged in the preparation process, so the stability of the metastable crystal form is greatly improved, and the growth of substances related with the medicines is controlled, thereby the integral stability of the medicines is enhanced.

Owner:TIANJIN TAIPU PHARMA SCI & TECH DEV

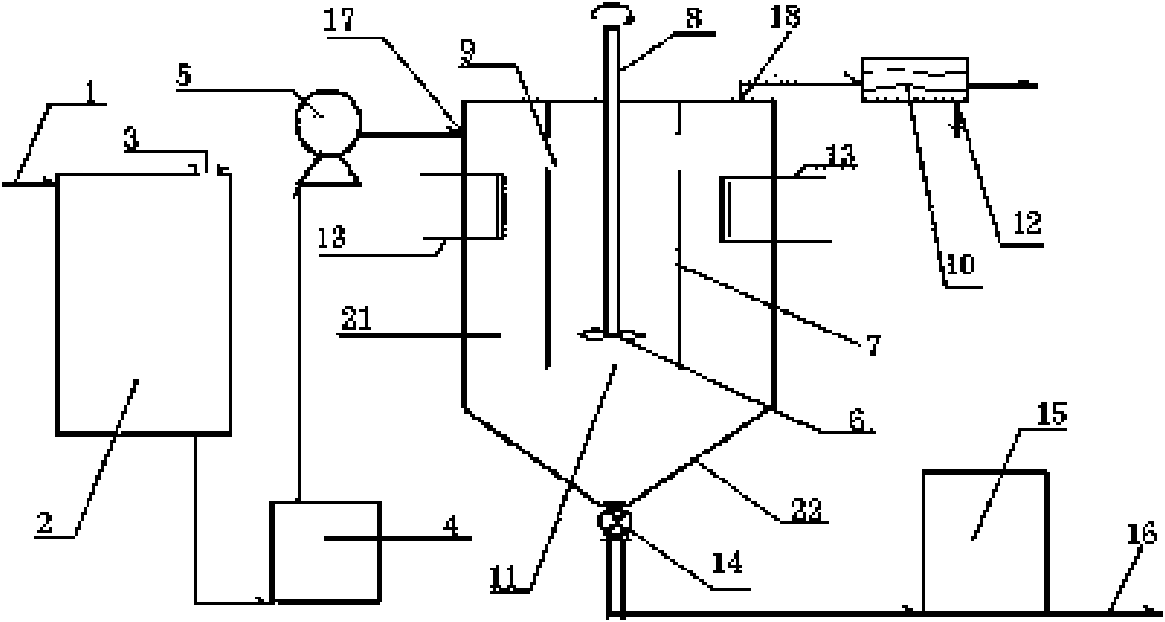

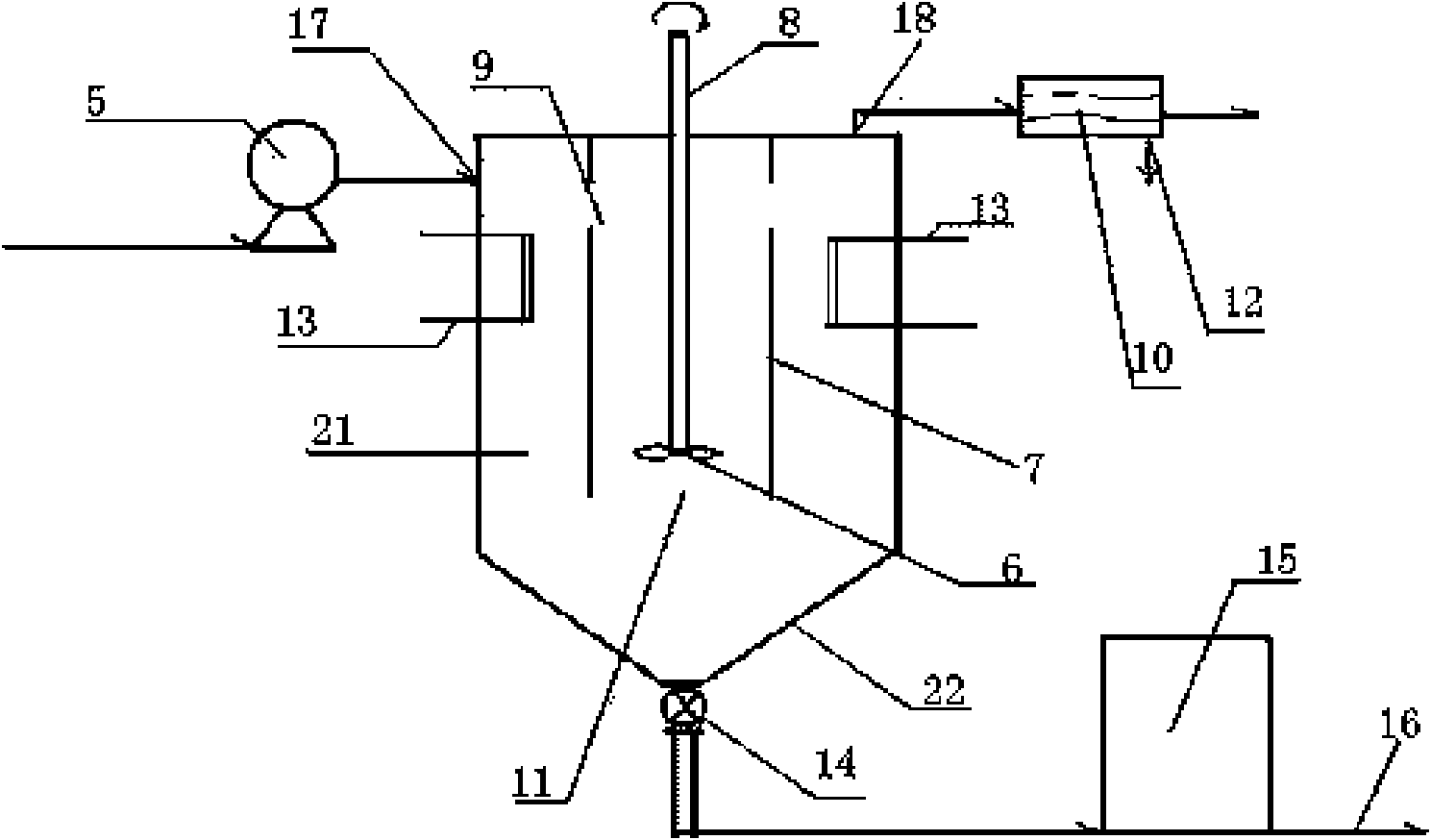

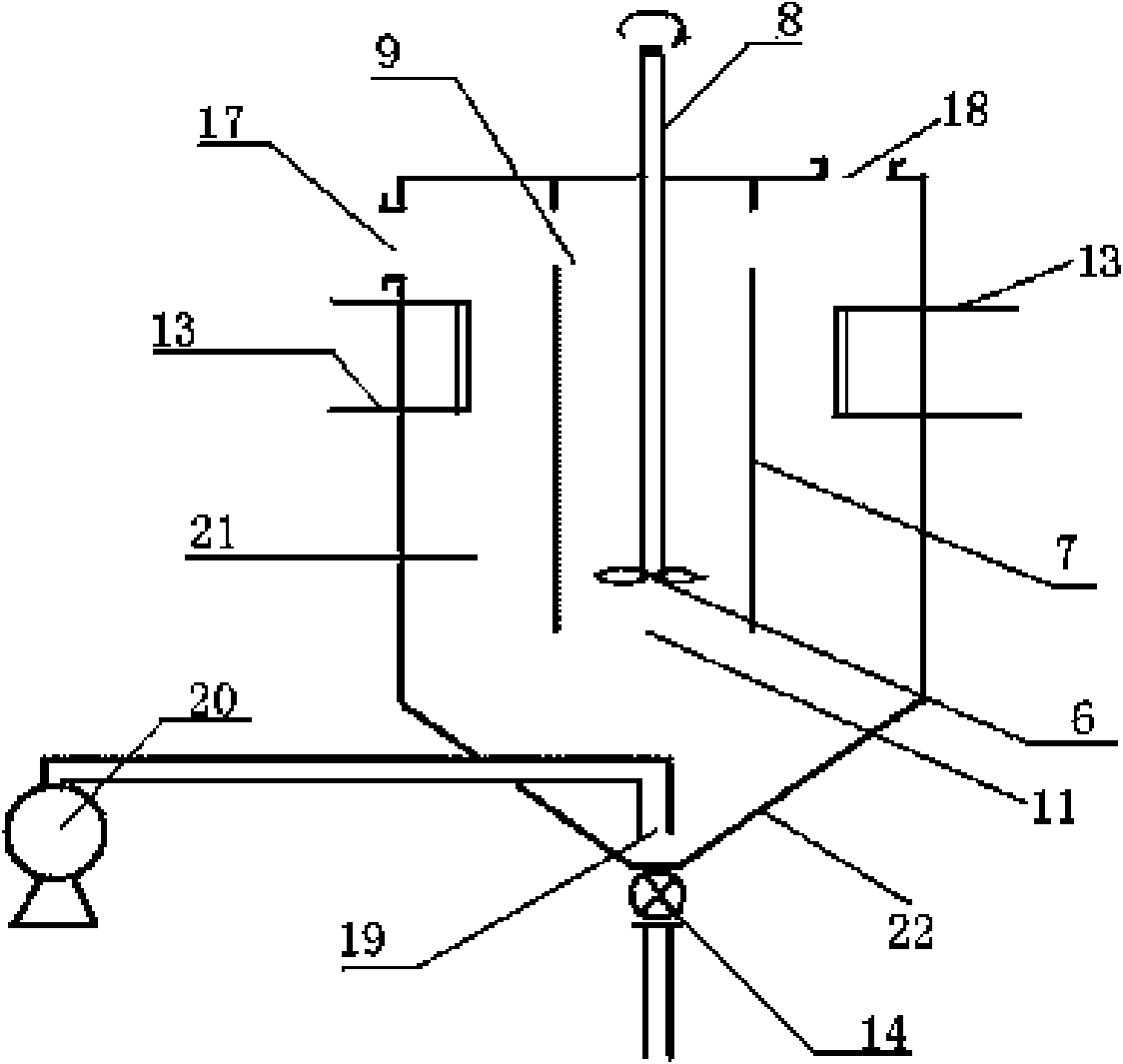

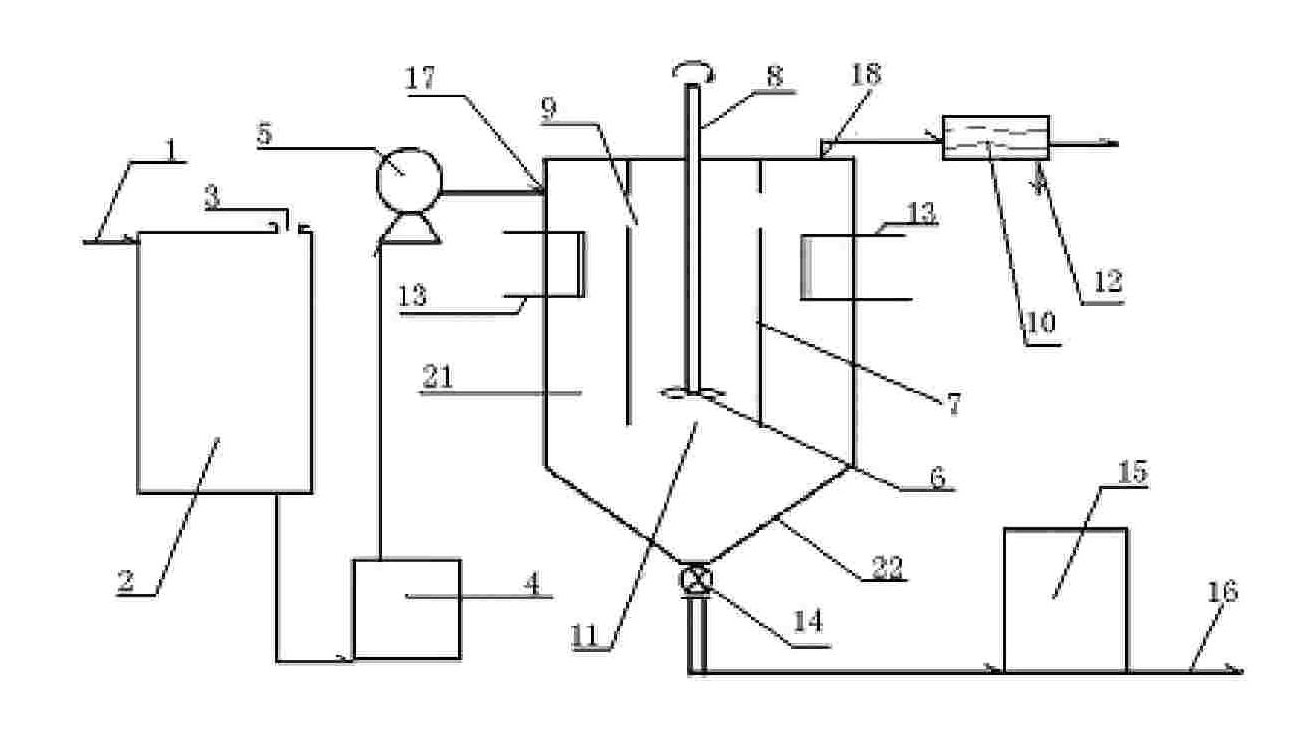

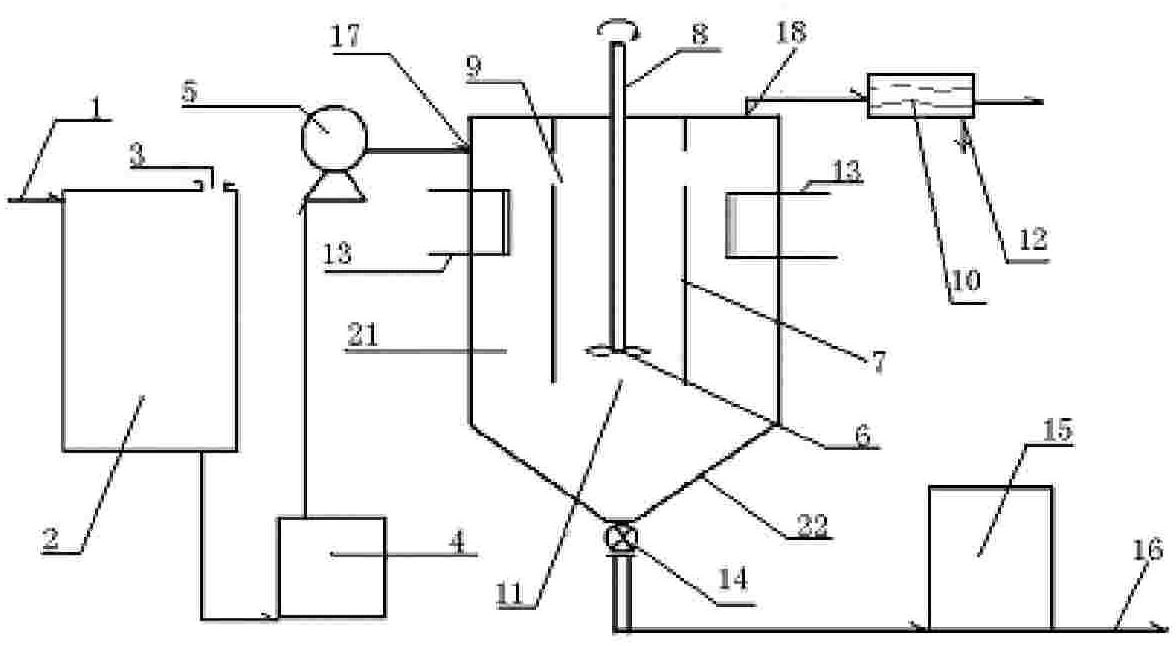

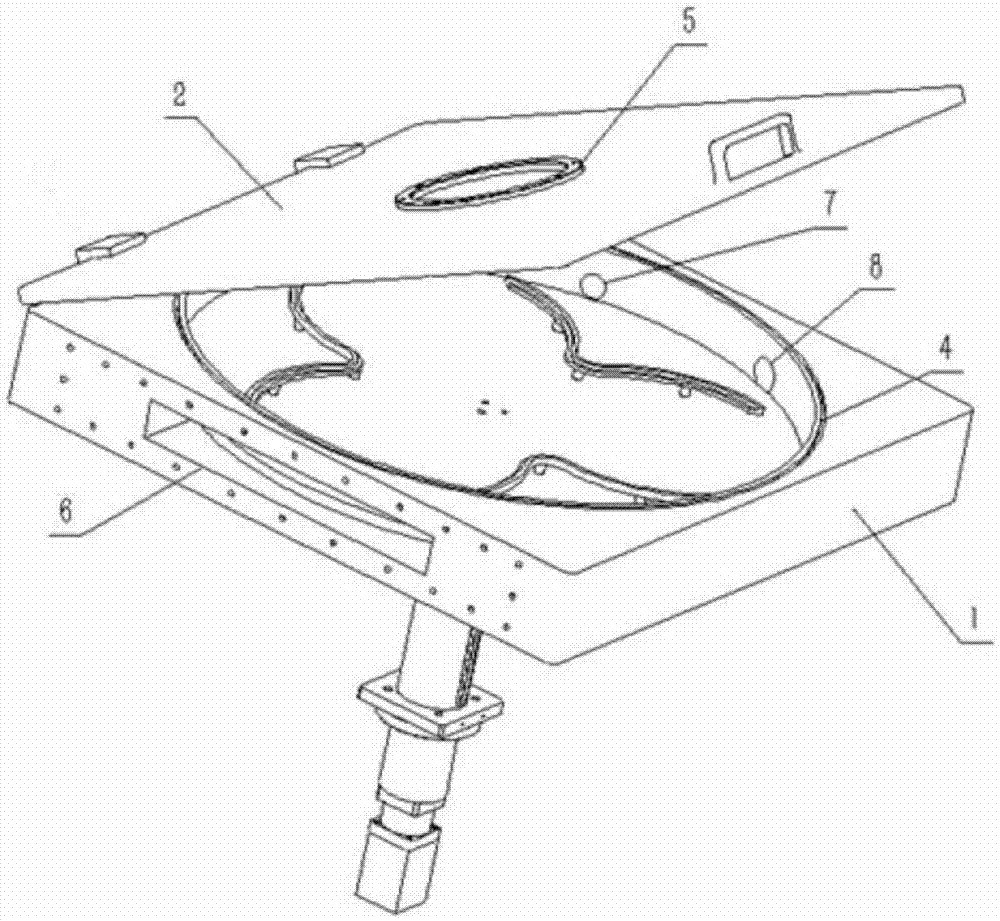

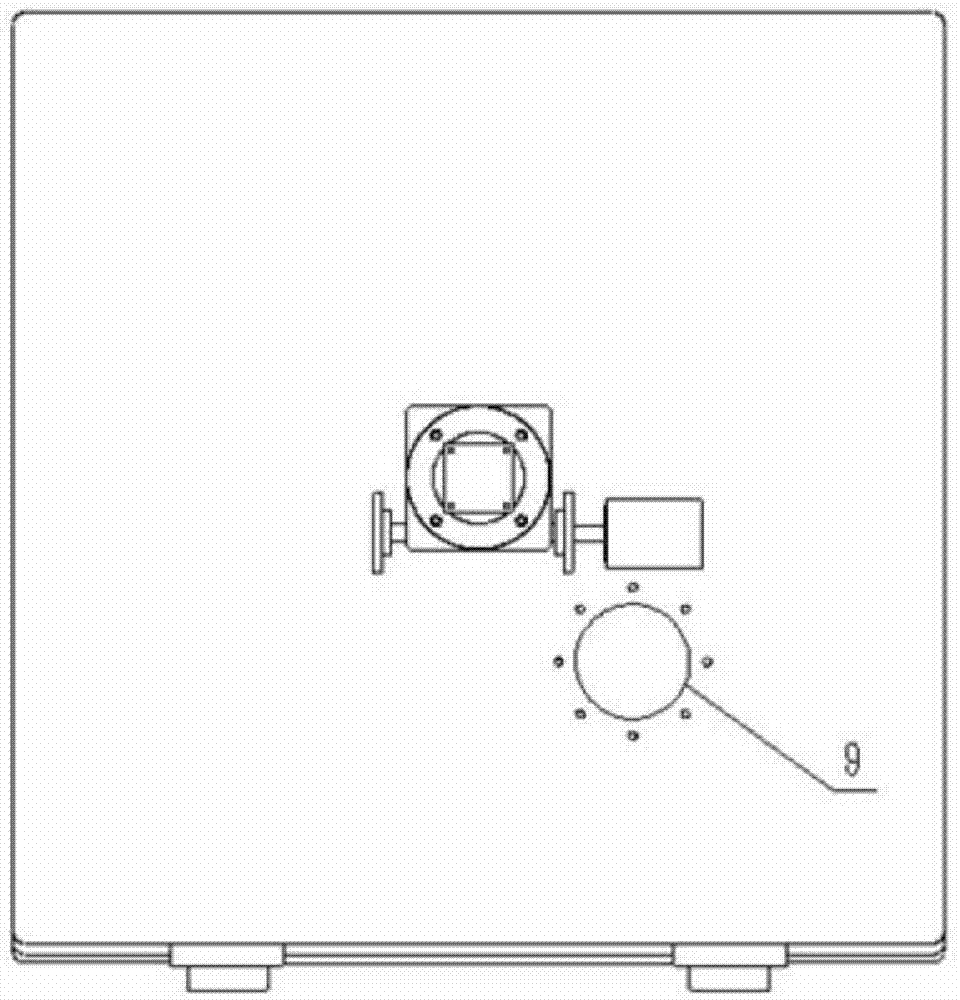

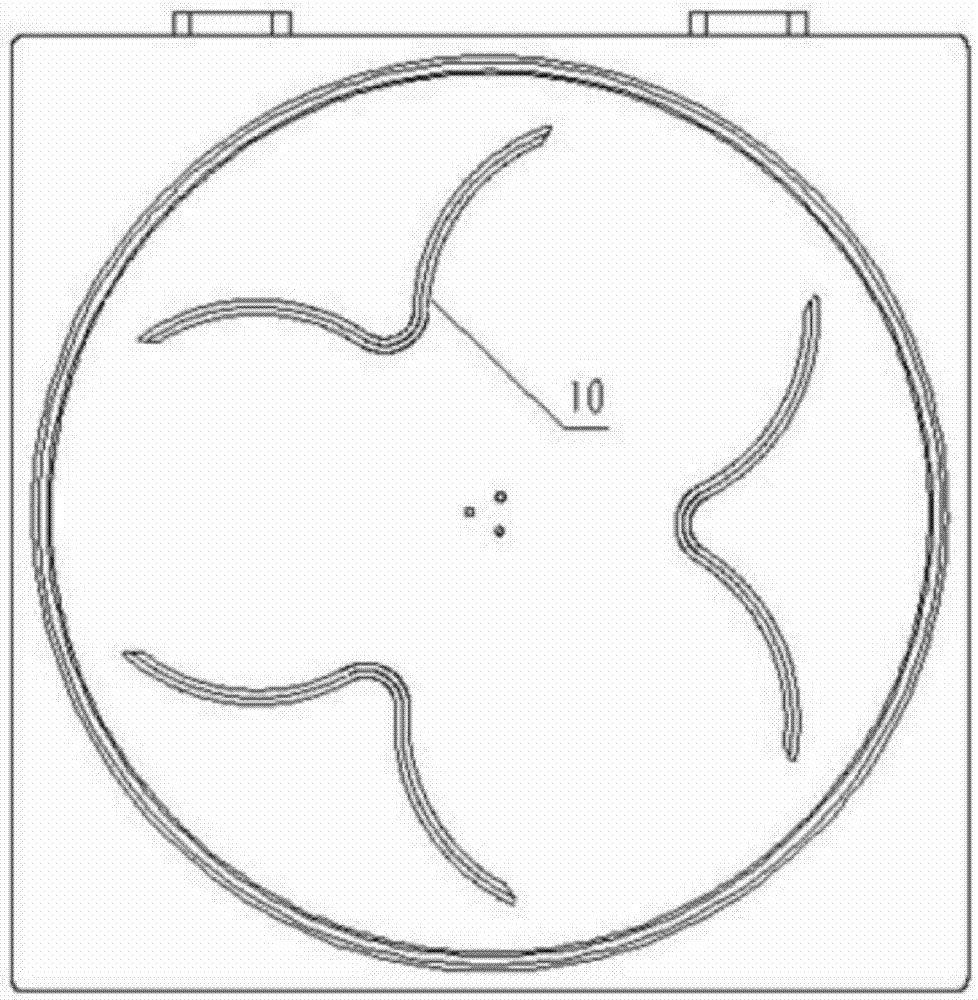

Continuous vacuum crystallization device and application thereof

InactiveCN101658735ASpeed up the flowCrystal stableSolution crystallizationEngineeringEnergy conservation

The invention discloses a continuous vacuum crystallization device and an application in the production of barium chloride, and the device comprises a crystallization pot, a raw material pump, a vacuum condensing recovery device, an electric heating temperature controlling device, a shaft flow pump and a bottom valve, wherein the bottom of the crystallization pot is in a conical shape, and the electric heating temperature controlling device is arranged at a place positioned above half height of the crystallization pot; the shaft flow pump is vertically arranged at the middle of the crystallization pot, the distance between the propeller of the pump and the top end of a conical body at the bottom of the crystallization pot is 1 / 3 time larger than the inner height of the crystallization pot,the propeller of the pump drives fluid raw materials upwards, and a liquid lifting pipe is arranged around the pump shaft of the shaft flow pump and the propeller of the pump; and the bottom of the crystallization pot can be also provided with a flow assisting device. The whole device is produced in enclosed environment, the process of crystallization is completed at one time, the device has continuous production process, high heating efficiency, stable fluid flow, stable and continuous crystallization, easy discharge for products and energy saving, and the device is not only suitable for large-scale industrial production, but also reduces environmental pollution and energy waste.

Owner:成都炘焓能机械设备有限公司

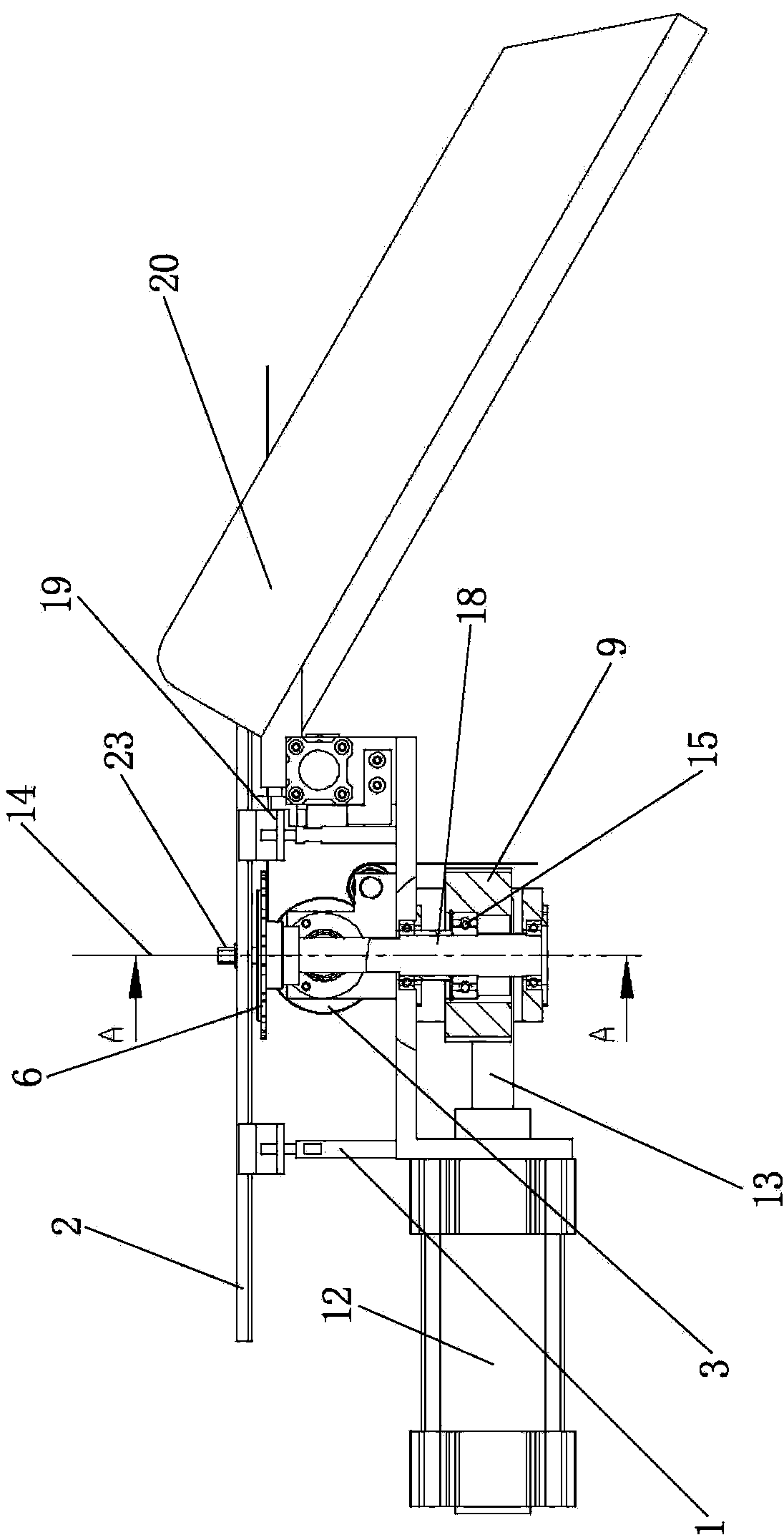

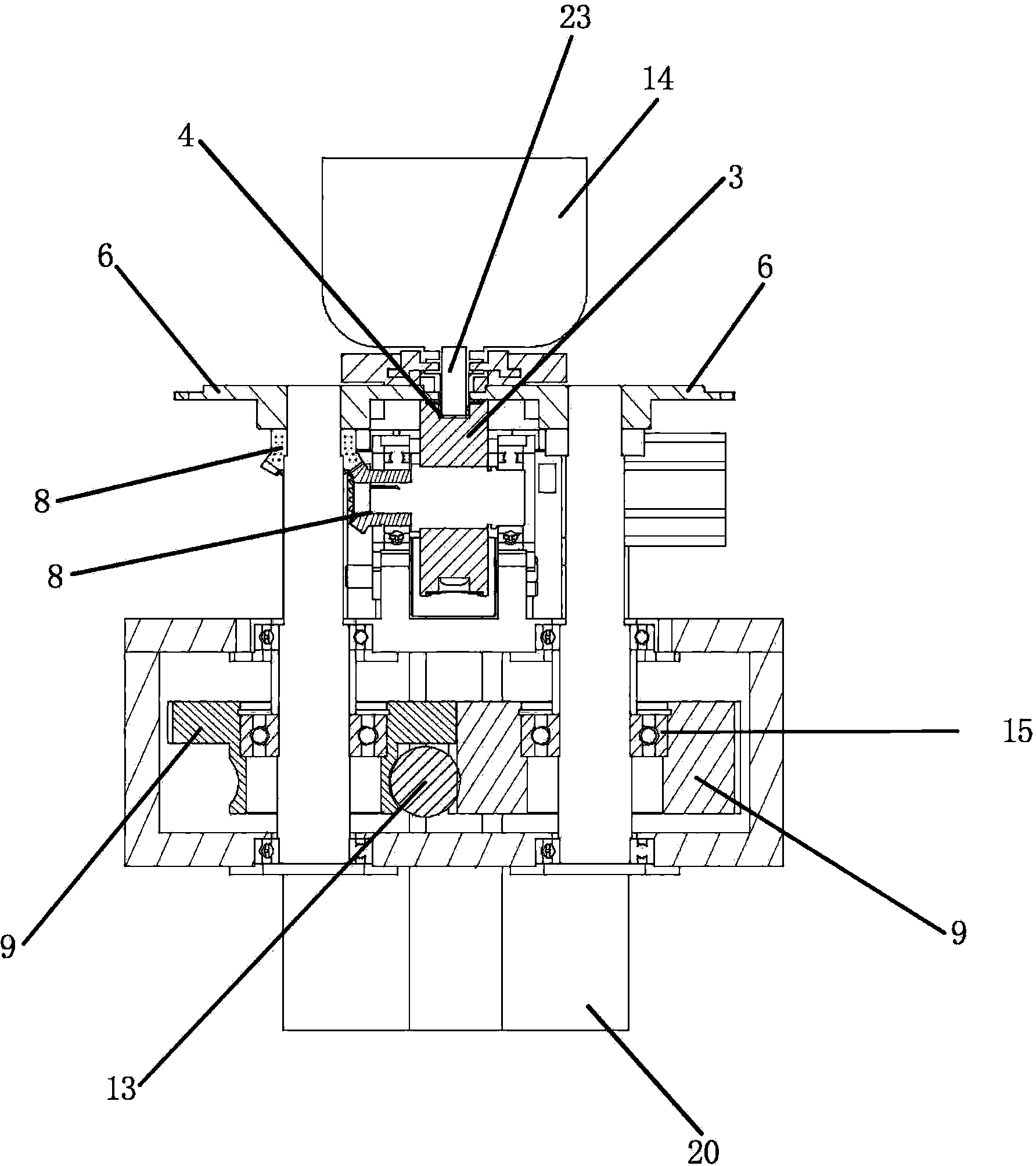

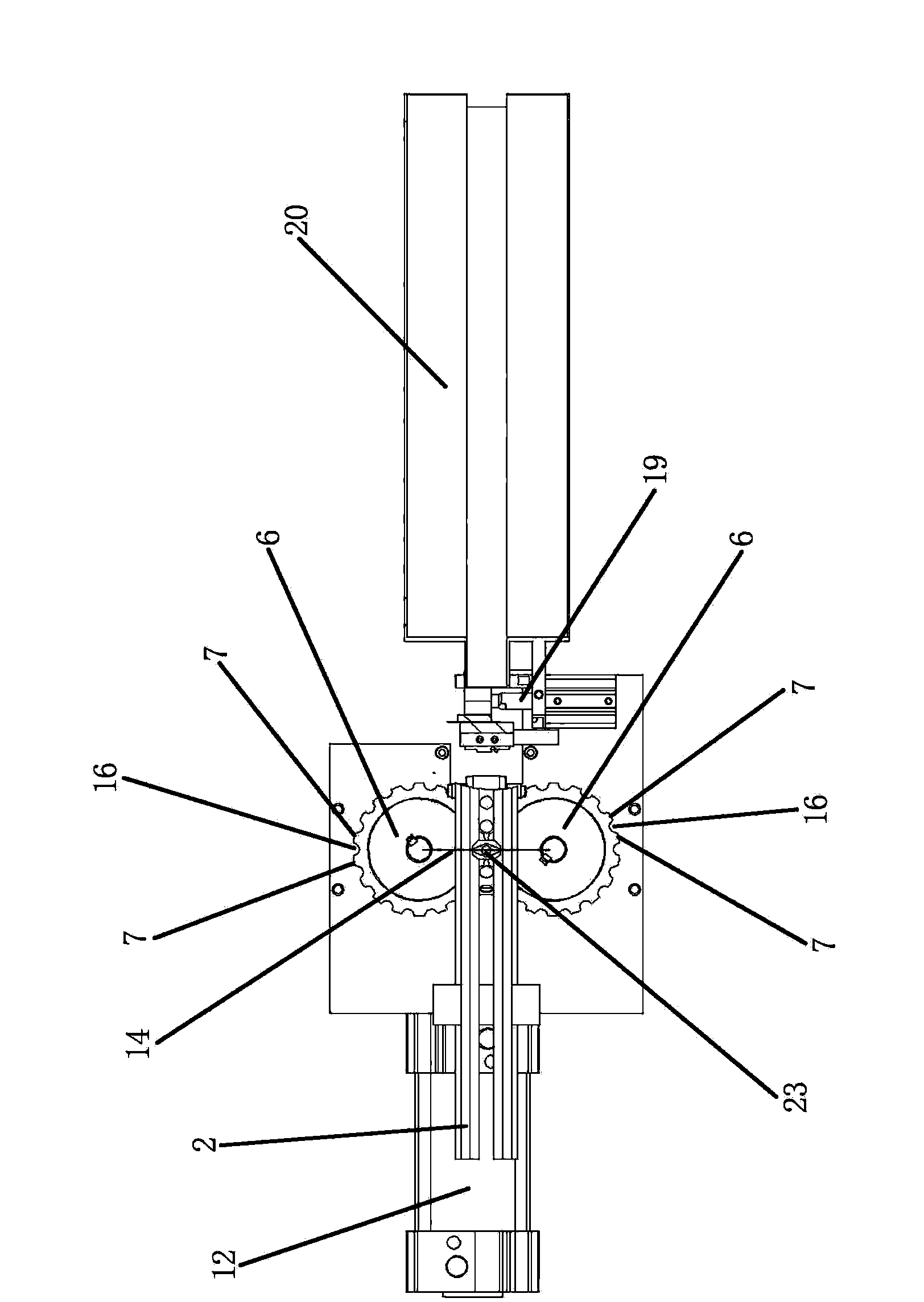

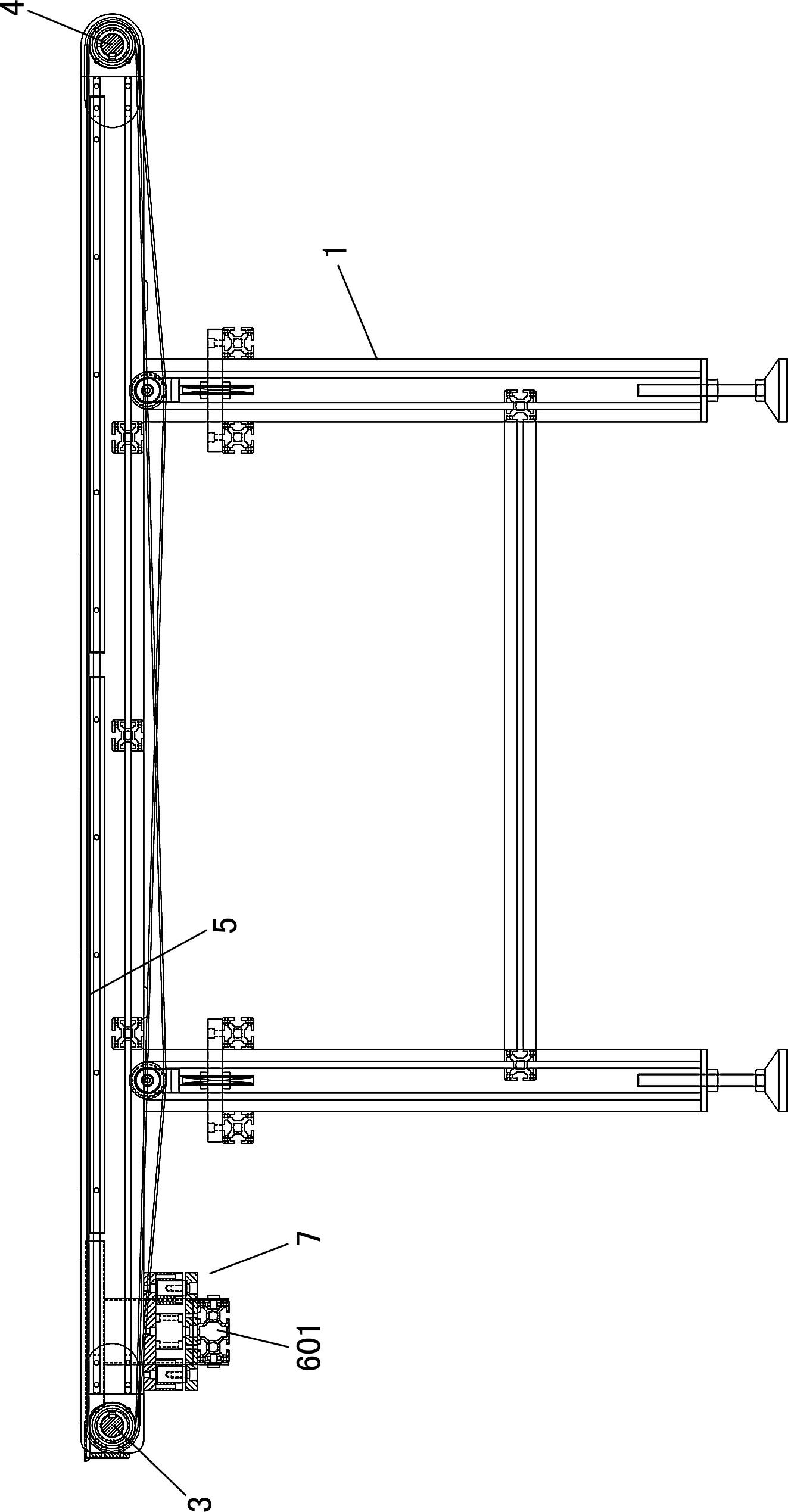

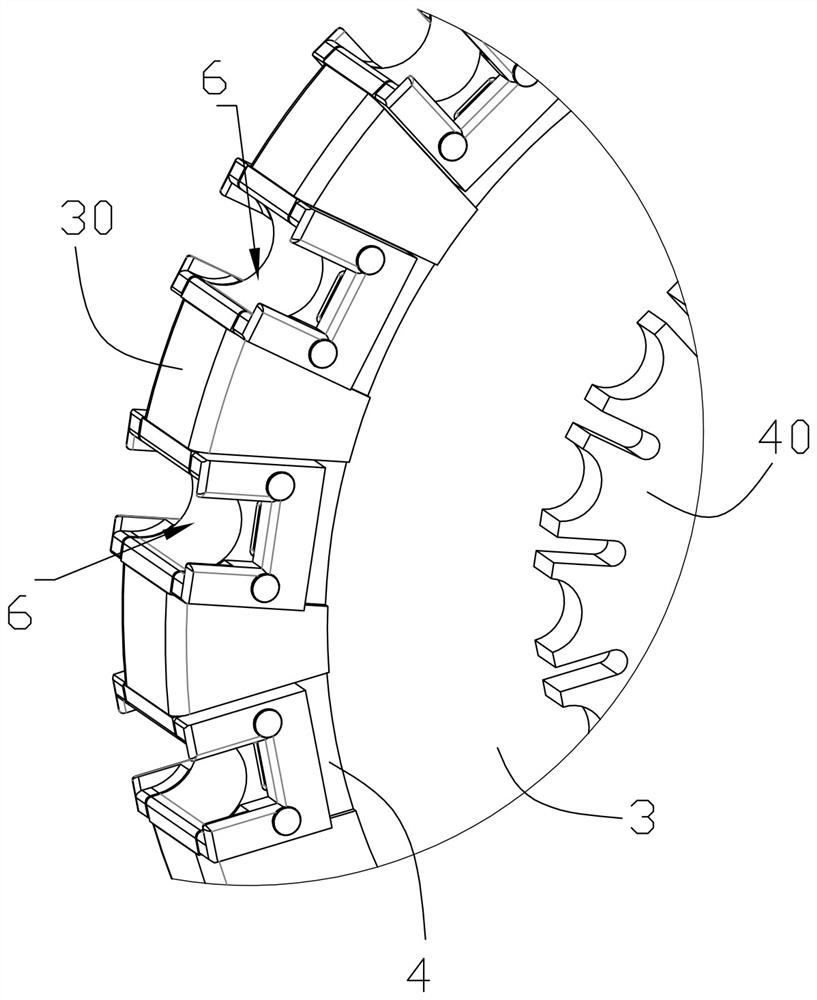

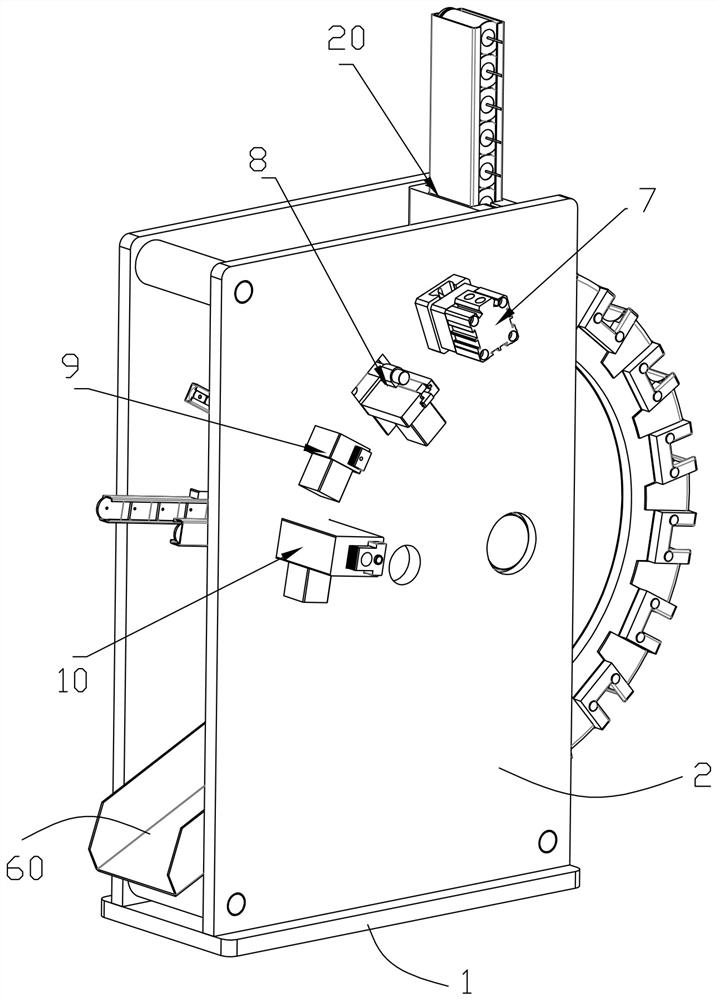

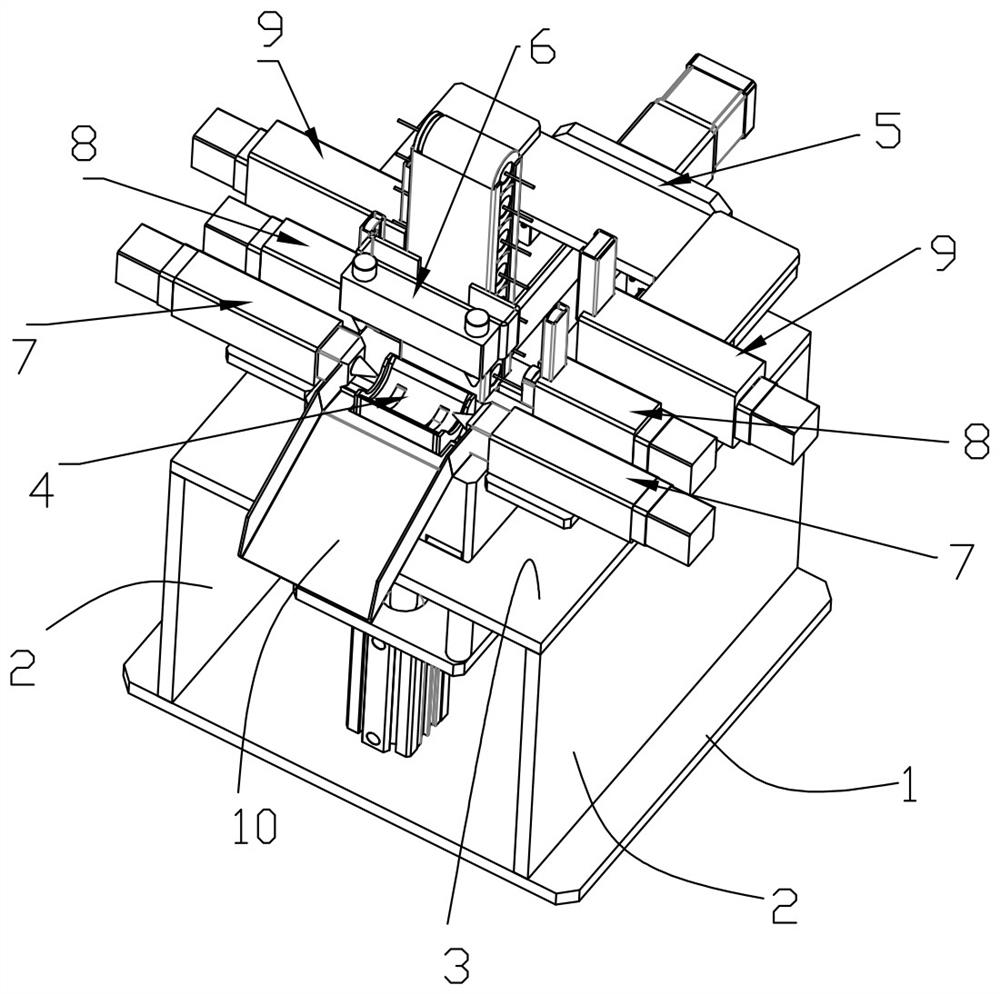

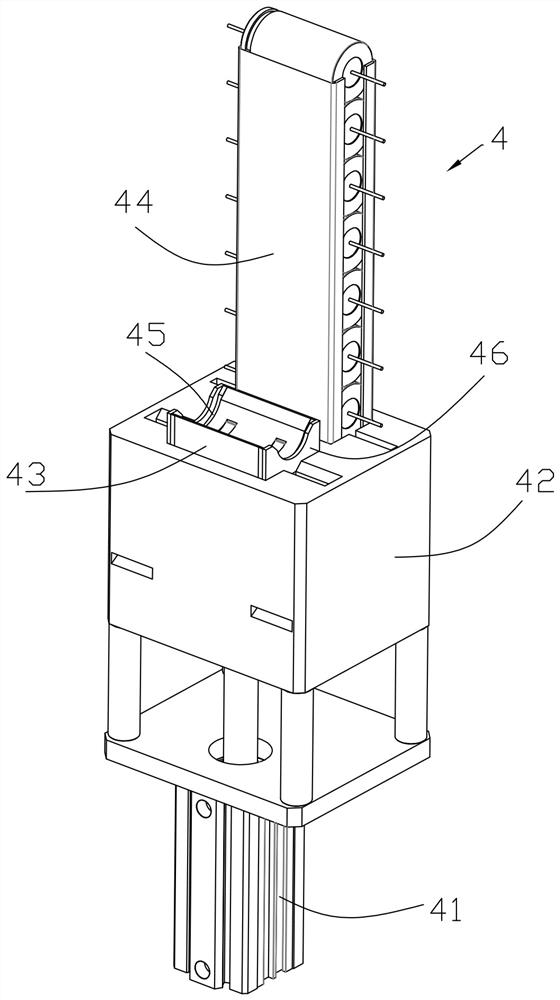

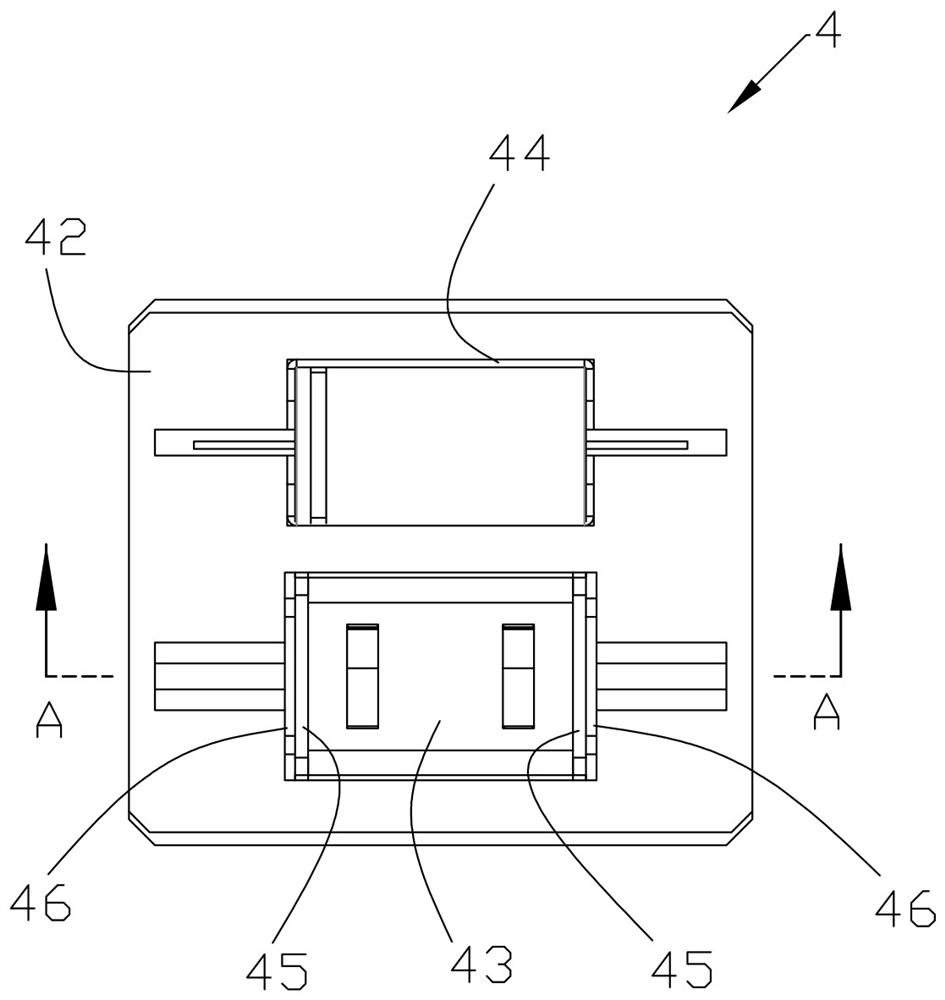

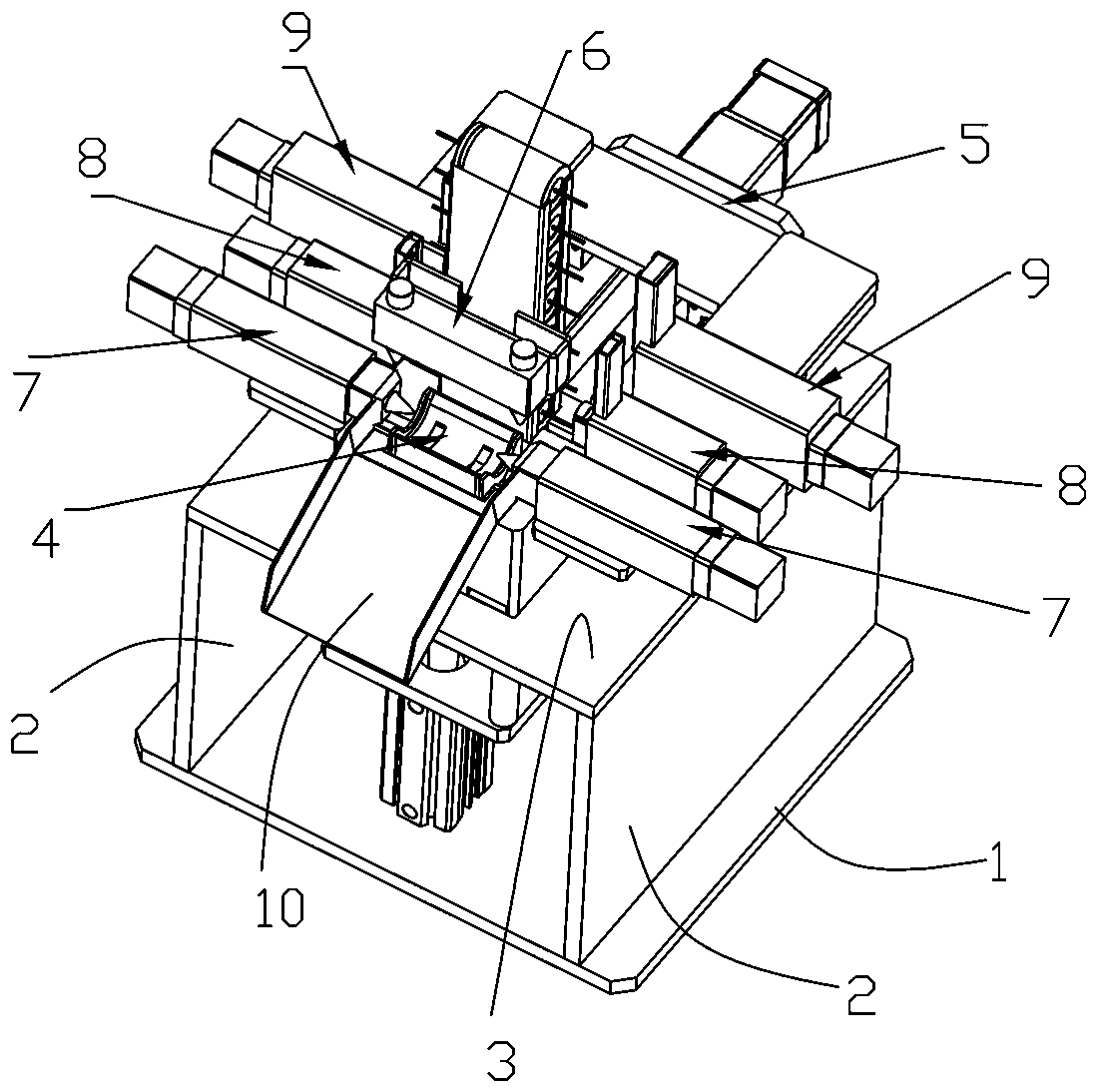

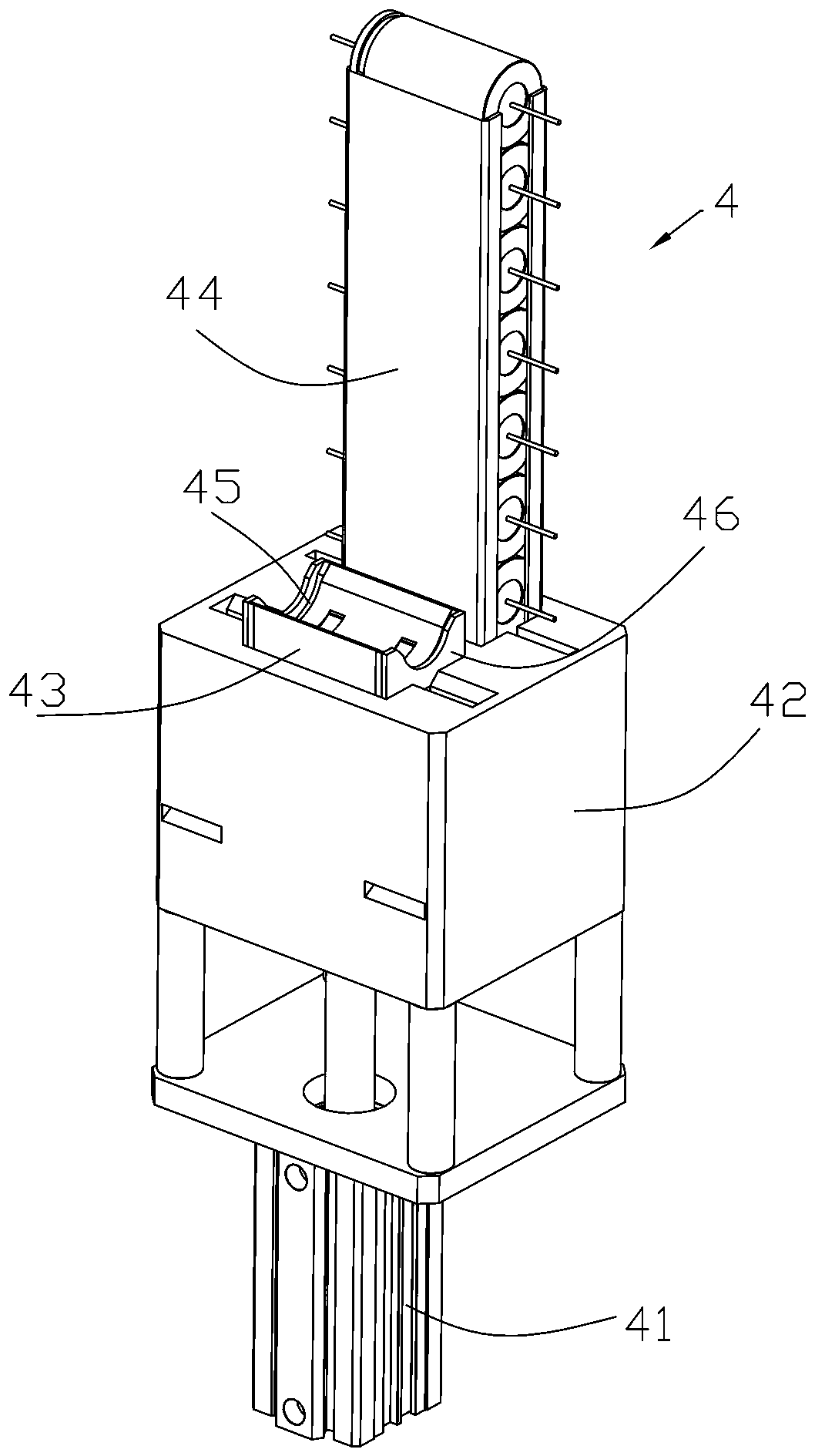

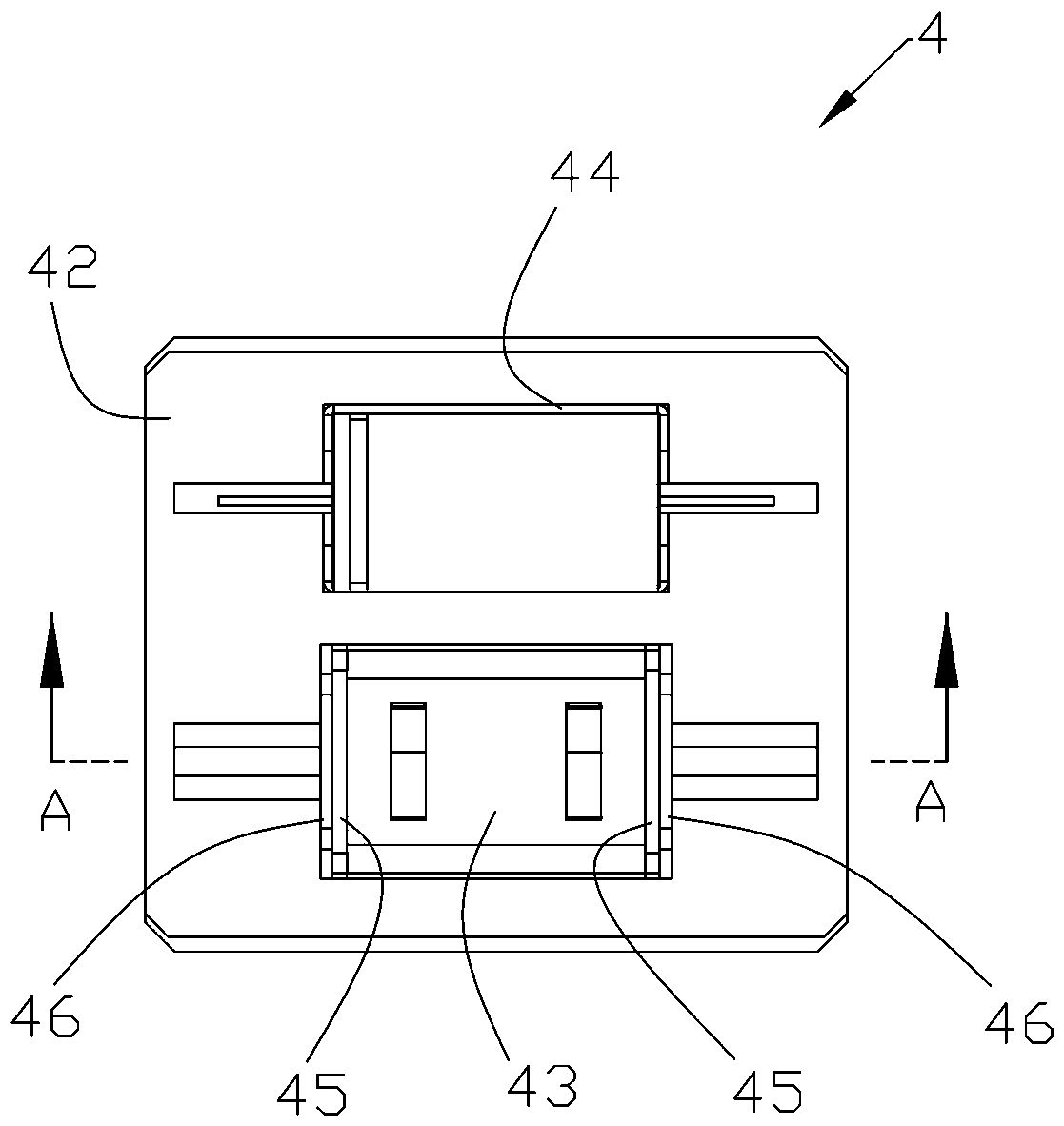

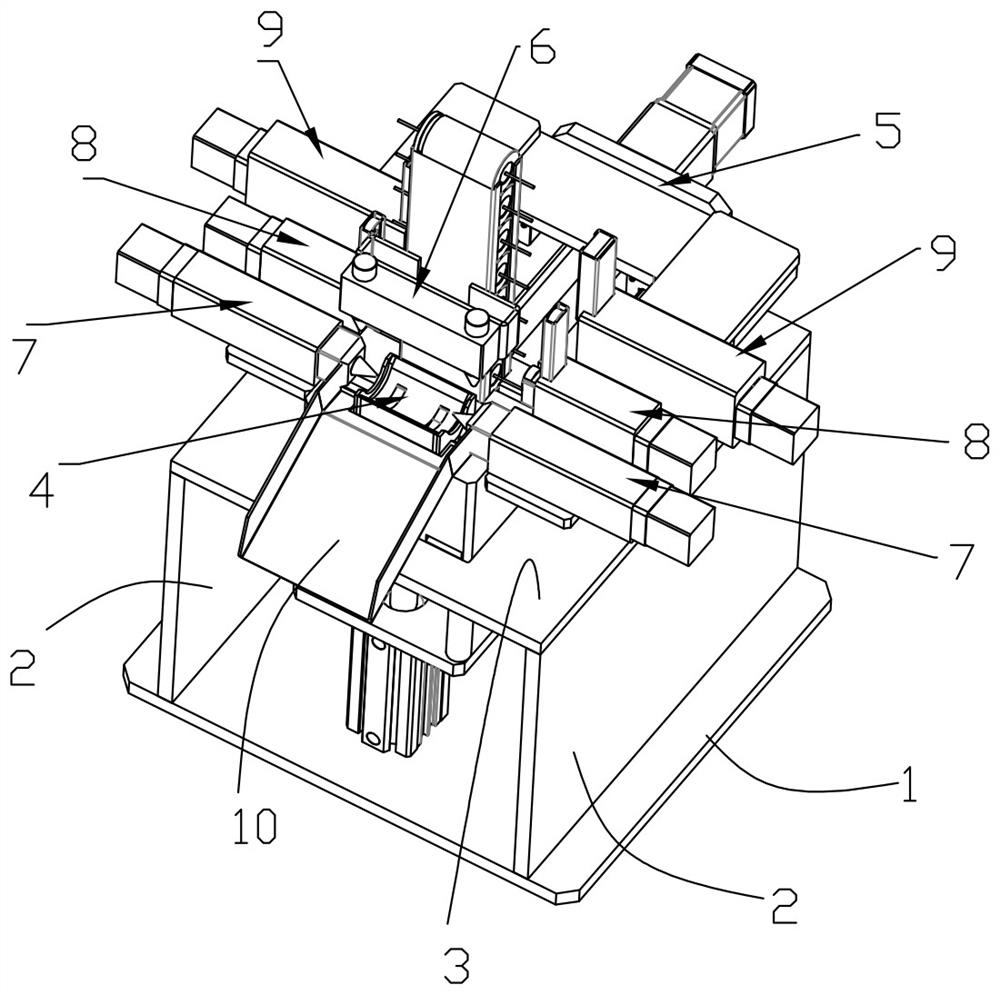

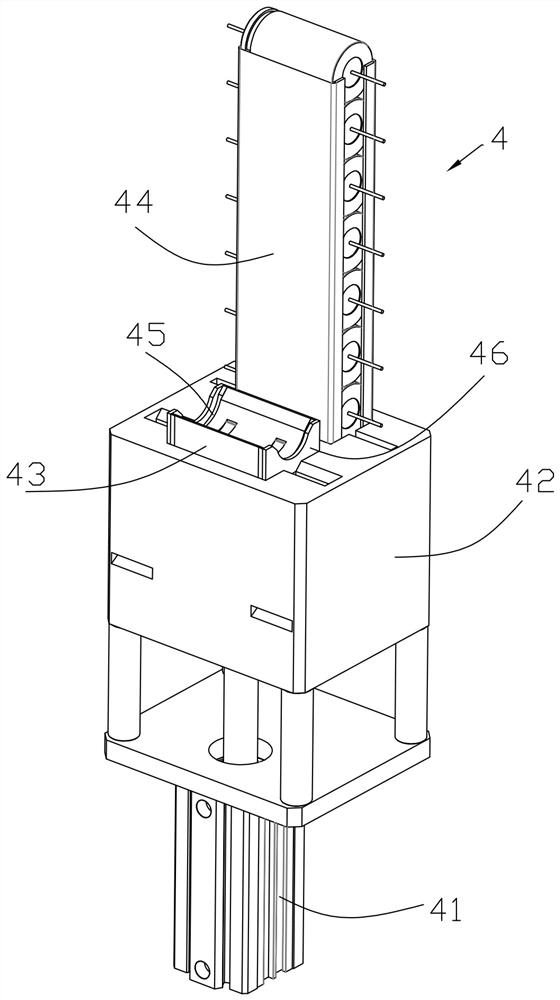

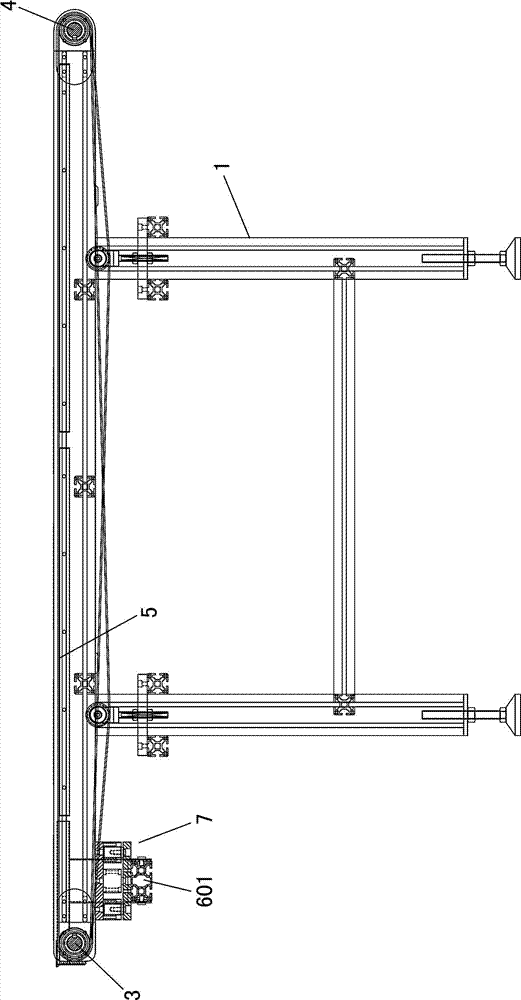

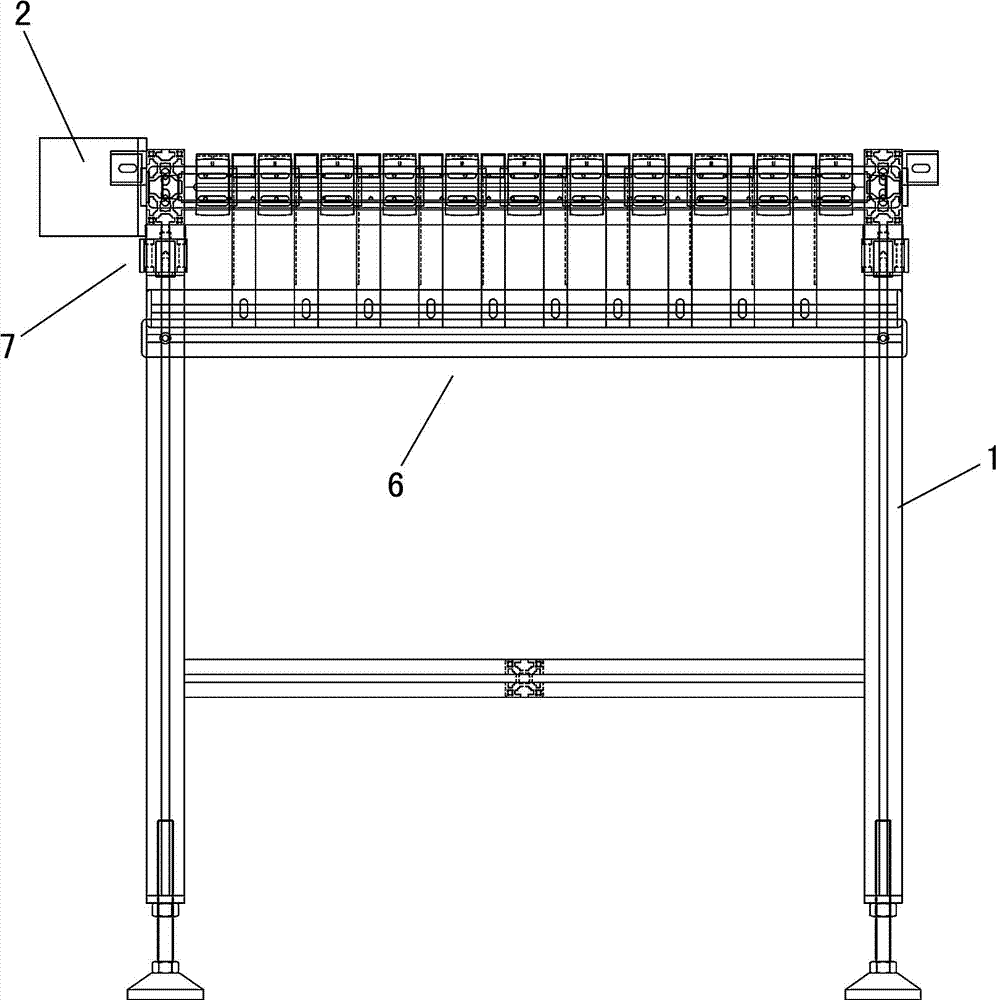

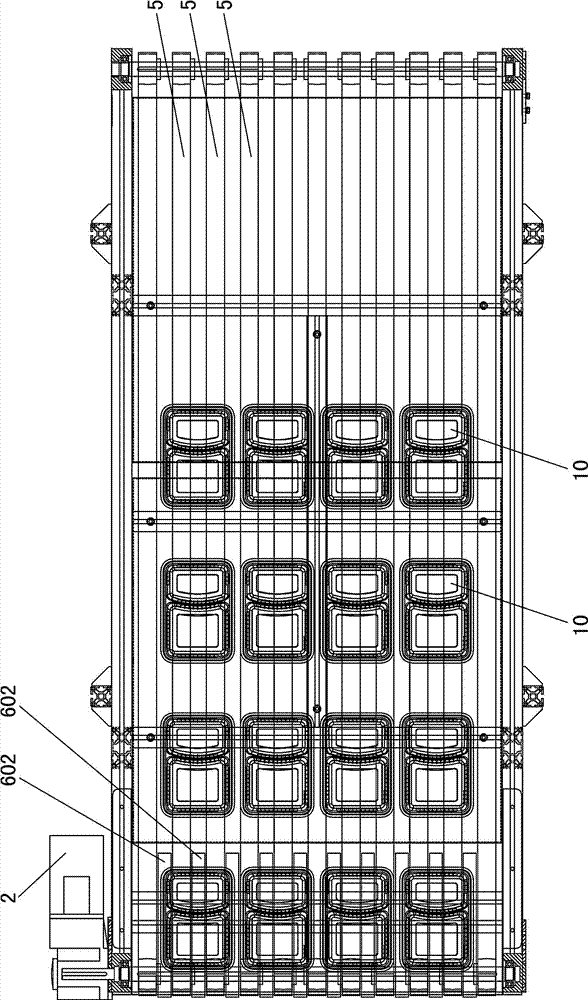

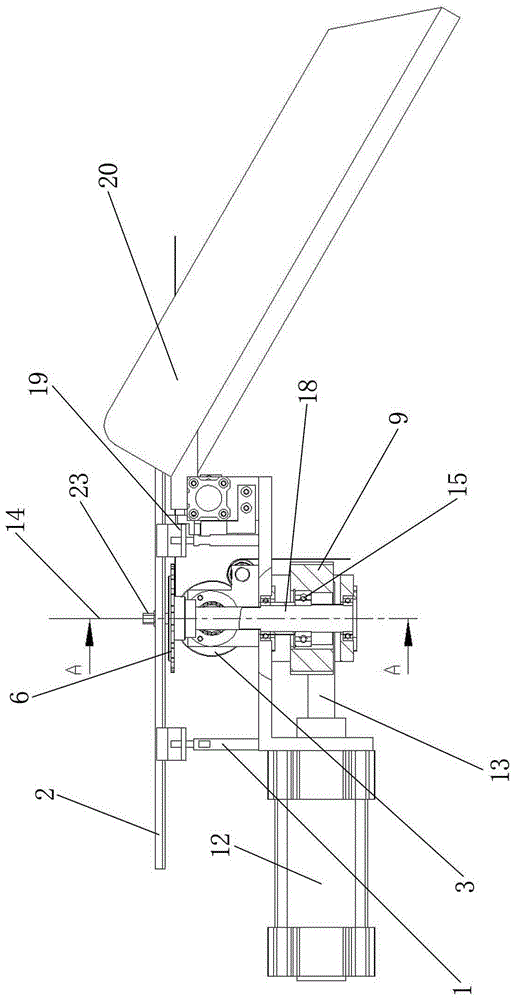

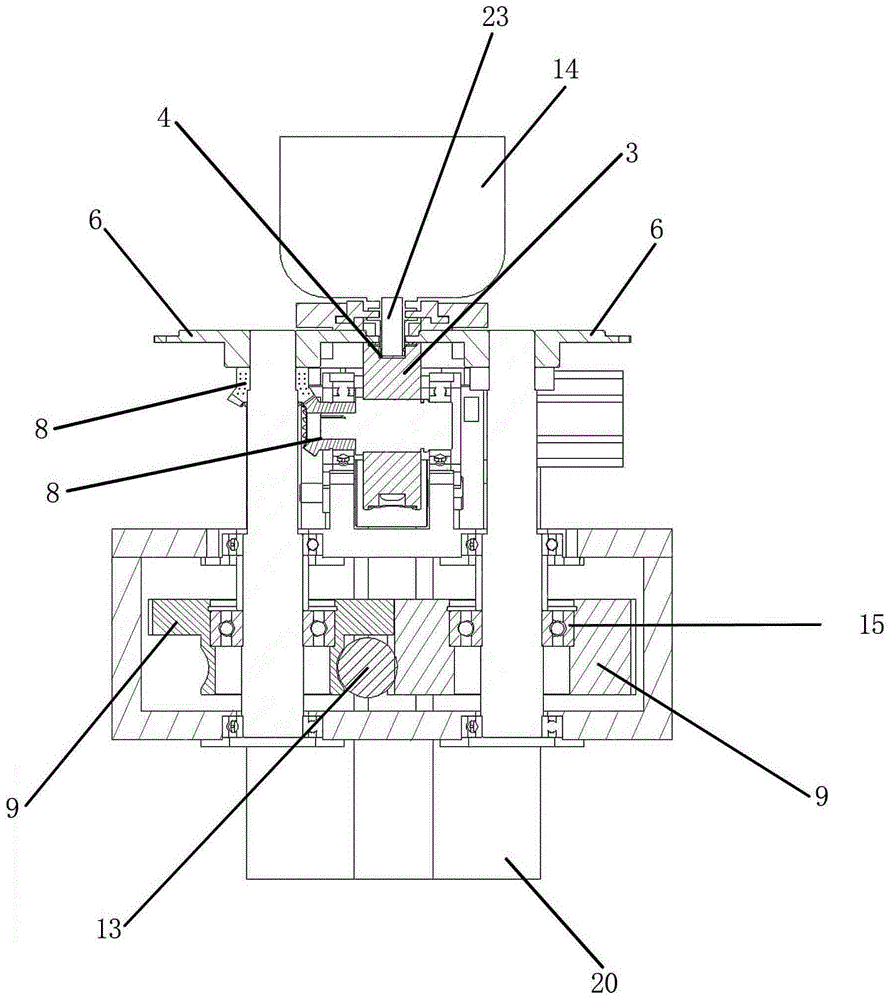

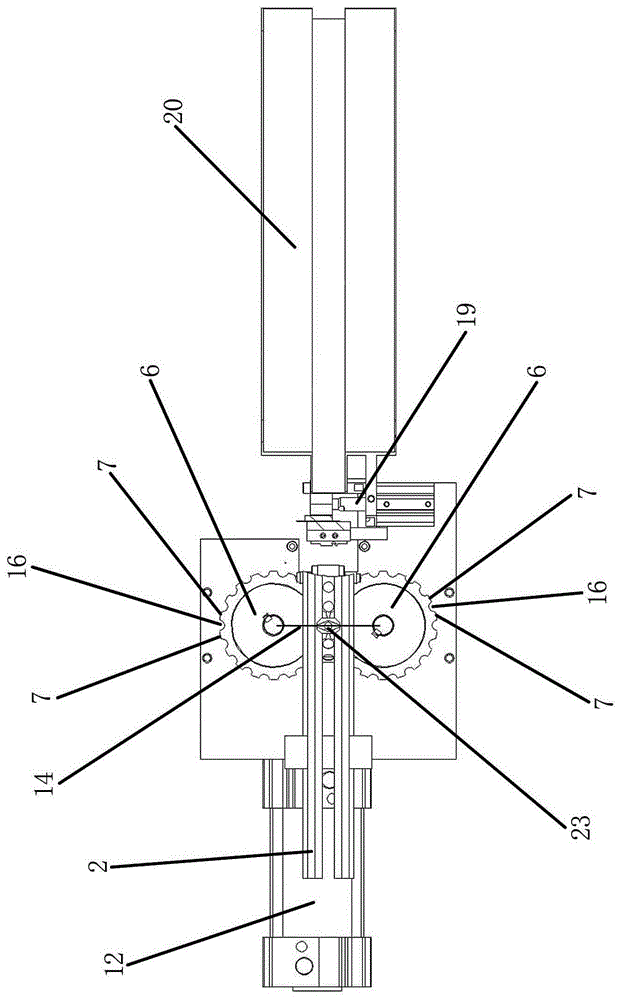

Threading device of packaging bags

ActiveCN103879758AImprove work efficiencyAdapt to the needs of large-scale industrial productionConveyor partsMechanical engineering

The invention relates to a threading device of packaging bags. The threading device comprises a rack and is characterized in that a filling drinking pipe locating sliding groove, a bunched sheet conveying mechanism, a clamping pressing pipe mechanism and a driving mechanism are arranged on the rack, wherein filling drinking pipe outlet sections of the packaging bags are limited in a groove in the mode of being capable of sliding along the groove through the filling drinking pipe locating sliding groove, the bunched sheet conveying mechanism is used for conveying packaging bag tidying bunched sheets, the clamping pressing pipe mechanism is used for clamping filling drinking pipes of the packaging bags, tidying a neck and pressing the filling drinking pipes into tidying locating holes of the packaging bag tidying bunched sheets, the driving mechanism respectively drives the bunched sheet conveying mechanism and the clamping pressing pipe mechanism to rotate, the clamping pressing pipe mechanism is located below the filling drinking pipe locating sliding groove, and the bunched sheet conveying mechanism is located below the clamping pressing pipe mechanism. The threading device of the packaging bags has the advantages that the bunched sheet conveying mechanism is matched with the clamping pressing pipe mechanism, the work that the multiple packaging bags are sequentially arranged and bunched on the packaging bag tidying bunched sheets can be automatically completed, the working efficiency is high, and the threading device can be suitable for large-scale industrial production requirements.

Owner:SHANTOU HONGQIAO PACKAGING IND

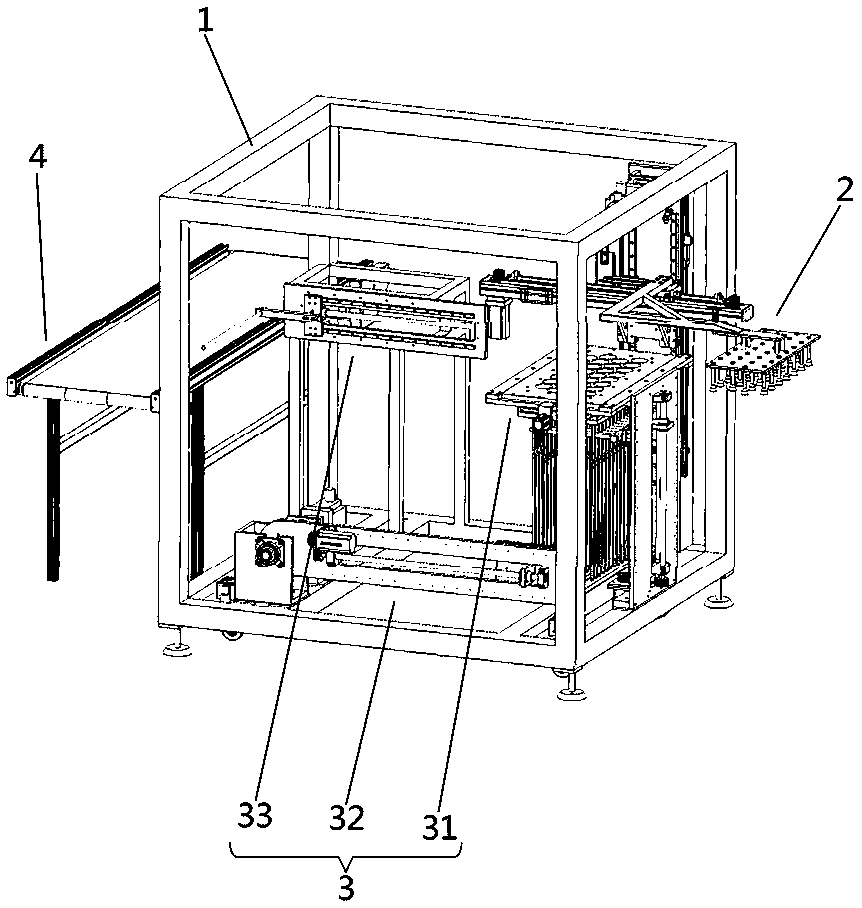

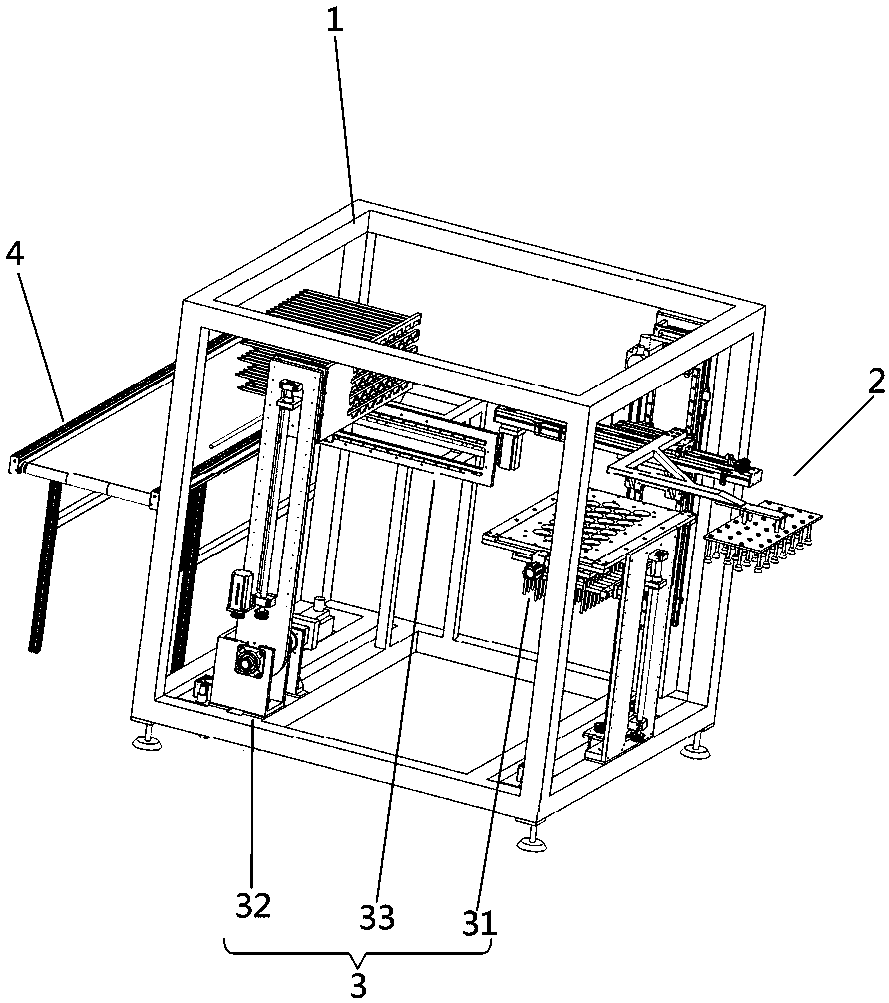

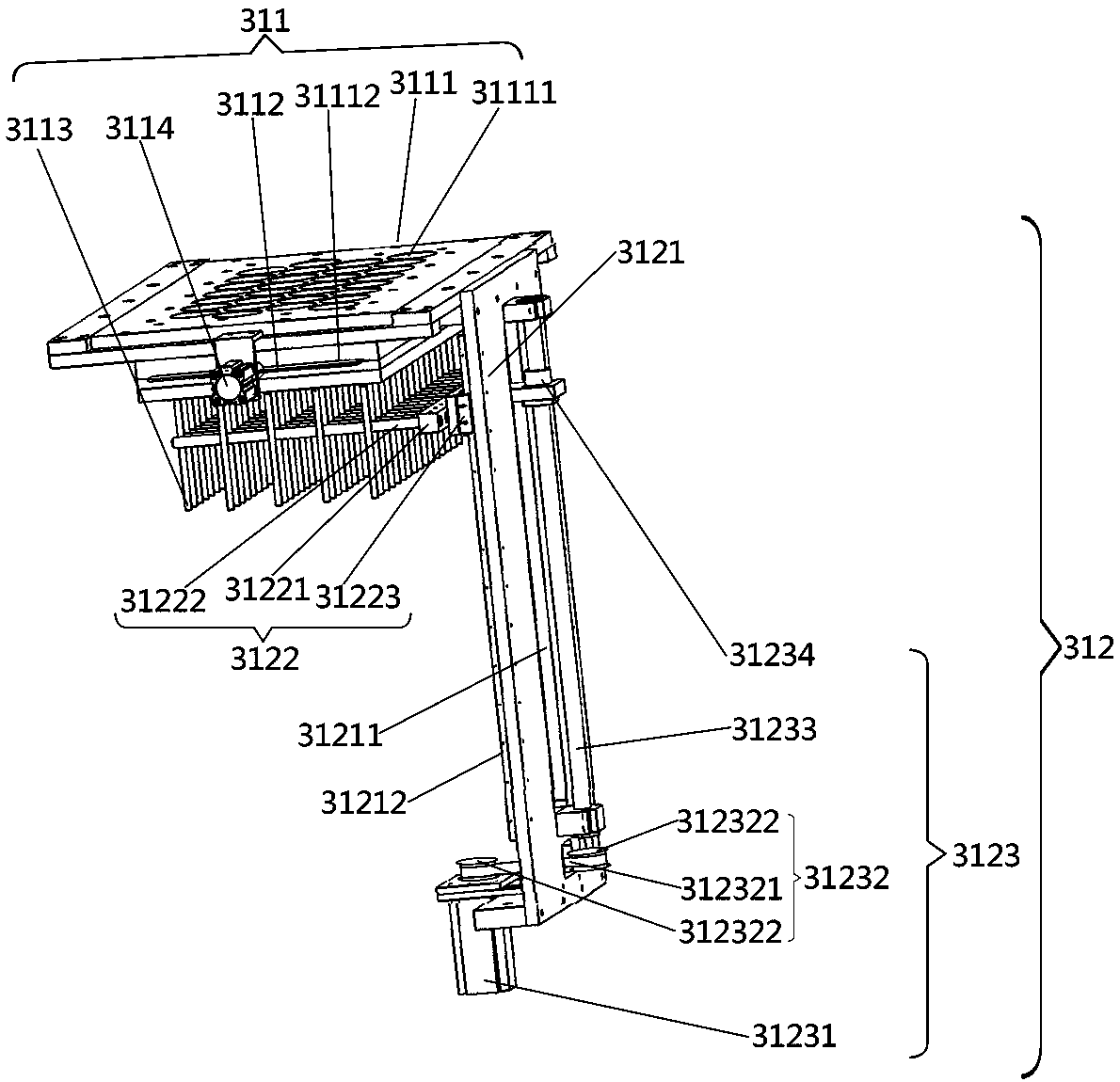

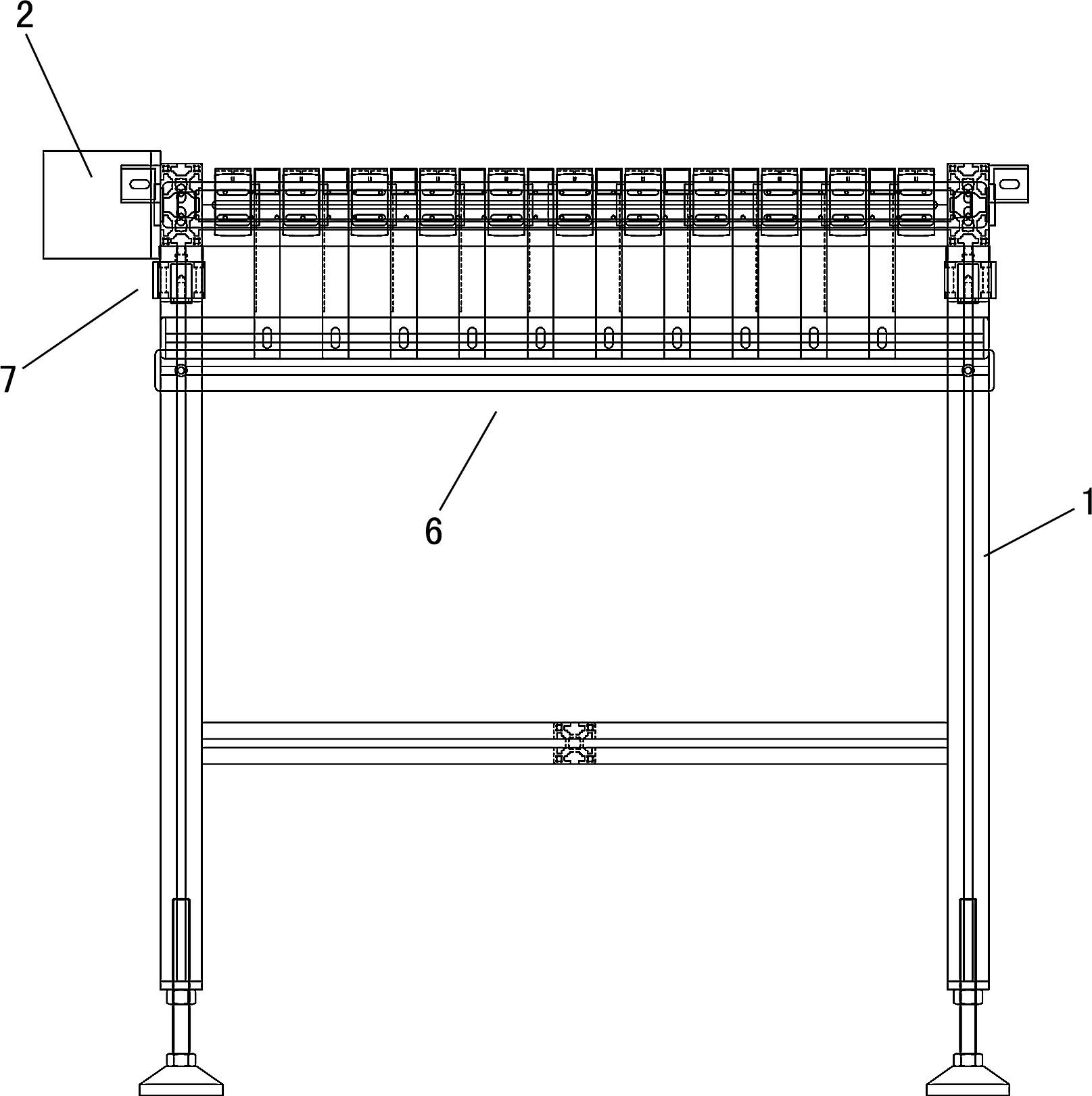

Full-automatic cup piling machine

ActiveCN109081122AGuarantee health statusImprove stacking effectStacking articlesEngineeringTransfer mechanism

The invention discloses a full-automatic cup piling machine which comprises a rack. The full-automatic cup piling machine is characterized by further comprising a plastic cup grasping and placing mechanism, a plastic cup piling device and a finished product conveying mechanism, wherein the plastic cup grasping and placing mechanism, the plastic cup piling device and the finished product conveyingmechanism are respectively mounted on the rack; the plastic cup piling device comprises a cup piling mechanism, a plastic cup collecting and transferring mechanism and a push mechanism; the cup pilingmechanism, the plastic cup collecting and transferring mechanism and the push mechanism are respectively mounted on the rack. Compared with the prior art, the full-automatic cup piling machine has the beneficial effects that due to adoption of the plastic cup grasping and placing mechanism, the plastic cup piling device and the finished product conveying mechanism, plastic cup piling and discharge can be automatically completed, and the whole process needs no manual operation, so that the sanitary situations of plastic cups can be ensured to the maximum extent; in addition, plastic cups can be well and rapidly piled, different mechanisms cooperate well, mistakes can be avoided, and the full-automatic cup piling machine is applicable to requirements of large-scale industrial production.

Owner:汕头市秉辉机械有限公司

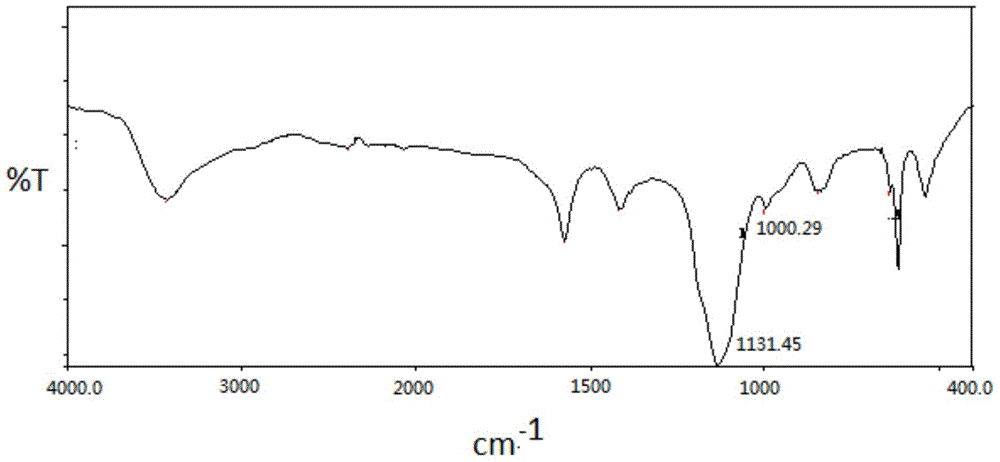

Preparation method and application of novel modified organic silicon softening agent

The invention discloses a preparation method and application of a novel modified organic silicon softening agent, and belongs to the technical field of textile chemical industry. The preparation method comprises the catalyst preparing process and the softening agent preparing process, wherein zinc sulfate and D-sodium gluconate solids are added into 100 ml of water to be mixed to prepare a catalyst solution, polysiloxane, butyl methacrylate and n-butyl acrylate are mixed and stirred, the catalyst solution is added after the temperature is increased, and a temperature increasing reaction is performed to obtain the modified organic silicon softening agent. The invention further discloses application of the organic silicon softening agent in a flax fabric finishing technology. The preparation method is simple, convenient, easy to operate, low in cost and suitable for the large-scale industrialized production requirement; after the novel modified organic silicon softening agent is applied to flax fabric finishing, the good flexibility and wrinkle resistance are given to flax fabric fiber, the smoothness and brightness are also excellent, and the extremely high market promotion value is achieved.

Owner:SUZHOU INSILK CO LTD

Receiving cup conveying belt of sheet forming machine

The invention discloses a receiving cup conveying belt of a sheet forming machine, and relates to a sheet forming machine, which comprises a belt conveying mechanism and is characterized by also comprising a product hoisting and transferring mechanism, wherein the belt conveying mechanism comprises a rack, a driving mechanism, a driving wheel, a driven wheel and at least two mutually parallel conveying belts, the driving wheel and the driven wheel are respectively fixed on the rack in a rotatable mode, each conveying belt is respectively sleeved on the driving wheel and the driven wheel, the driving mechanism is connected with the driving wheel, and the product hoisting and transferring mechanism is fixed on the rack and is positioned between the driving wheel and the driven wheel and at the inner side of each conveying belt. According to the conveying belt disclosed by the invention, the situation of product toppling-over is effectively avoided, so that the number of products conveyed by the transferring mechanism every time can be greatly increased, the working efficiency is effectively improved, and the need of large-scale industrial production can be met.

Owner:大连达诚环保机械有限公司

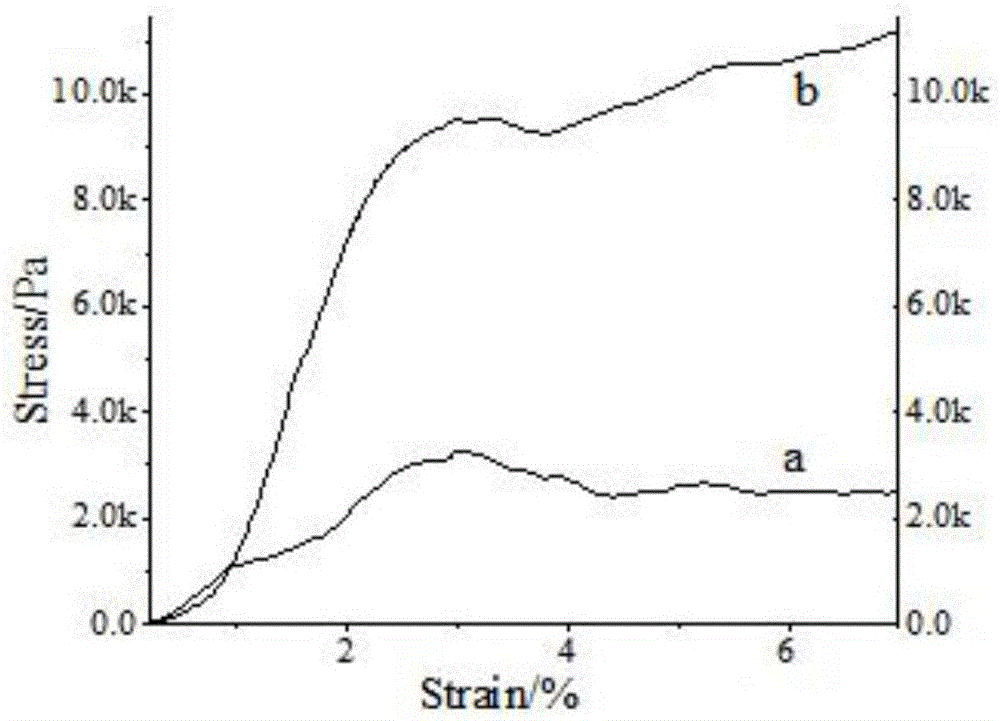

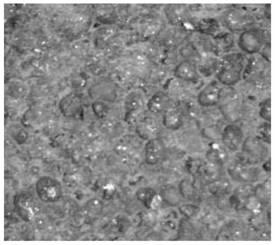

Polyurethane and foamed cement microscopically-composite heat insulating material and preparation method therefor

ActiveCN106565167AComposite interface stabilityGood weather resistanceCeramicwarePolyolRoom temperature

The invention provides a polyurethane and foamed cement microscopically-composite heat insulating material and a preparation method therefor and belongs to the field of organic / inorganic composite type building materials. The preparation method is characterized by comprising the steps: adding ingredients such as cement and a foam stabilizer according to the conventional method, preparing foamed cement through carrying out foaming with hydrogen peroxide, and then, carrying out room-temperature curing until the foamed cement reaches an age; and then, mixing isocyanate, polyether polyol, polysiloxane polyether and a catalyst so as to obtain uniform slurry, then, submerging the dried foamed cement in the slurry, taking out the foamed cement after the foamed cement is completely impregnated with the slurry, carrying out standing for 2 to 4 hours so as to cure the foamed cement, then, submerging the foamed cement in water again, and then, carrying out foaming in a manner that water molecules are in contact with incompletely-reacted isocyanate through diffusion and infiltration, thereby obtaining the microscopically-composite heat insulating material. According to the material, organic polyurethane foam and inorganic cement foam are mutually independent and coexist in an interpenetrating manner, and microscopic compounding among interfaces is achieved, so that the foamed cement has relatively high compressive strength and relatively low coefficient of thermal conductivity.

Owner:CENT SOUTH UNIV

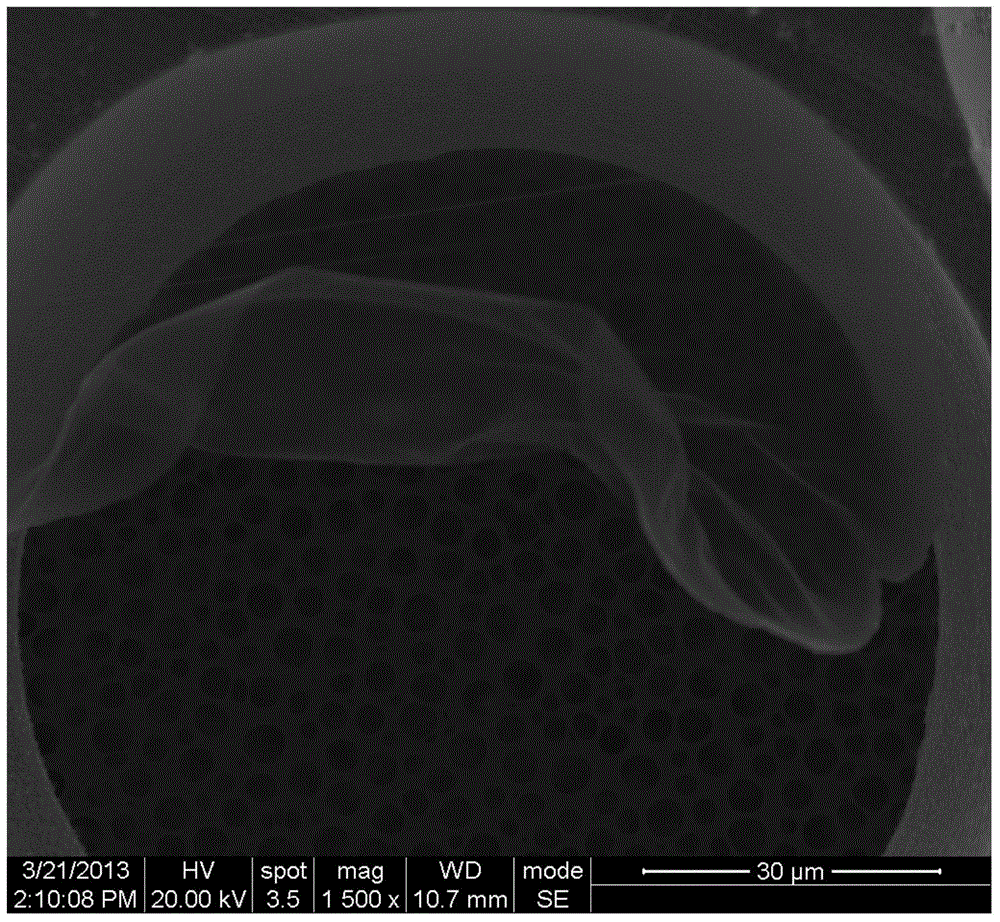

High-transparency cellulose acetate material and preparation method thereof

ActiveCN113896952AReduce dosageReduce risk of precipitationBio-packagingPolymer scienceCellulose acetate

The invention discloses a high-transparency cellulose acetate material and a preparation method thereof. The high-transparency cellulose acetate material comprises the following raw materials by weight: 100 parts of cellulose acetate, 17-25 parts of a plasticizer, 0.1-2 parts of a cross-linking agent, and 0.1-2 parts of other auxiliary agents. The cross-linking agent is selected from isocyanate, dianhydride or peroxide; and the melting point of the cross-linking agent is not higher than 120 DEG C. The preparation process comprises the following steps of uniformly blending all the raw materials, performing heating treatment to perform melting pre-crosslinking modification, and then performing extrusion, granulation and drying to obtain the high-transparency cellulose acetate material. According to the cellulose acetate material prepared by adopting the raw materials and the process, the use amount of a plasticizer is remarkably reduced, and the risk of precipitation is reduced; and the prepared cellulose acetate material has the advantages of high light transmittance, low haze, simple and convenient process flow, short time consumption and high production efficiency, and is suitable for large-scale industrial production.

Owner:SUZHOU HSM TECH CO LTD

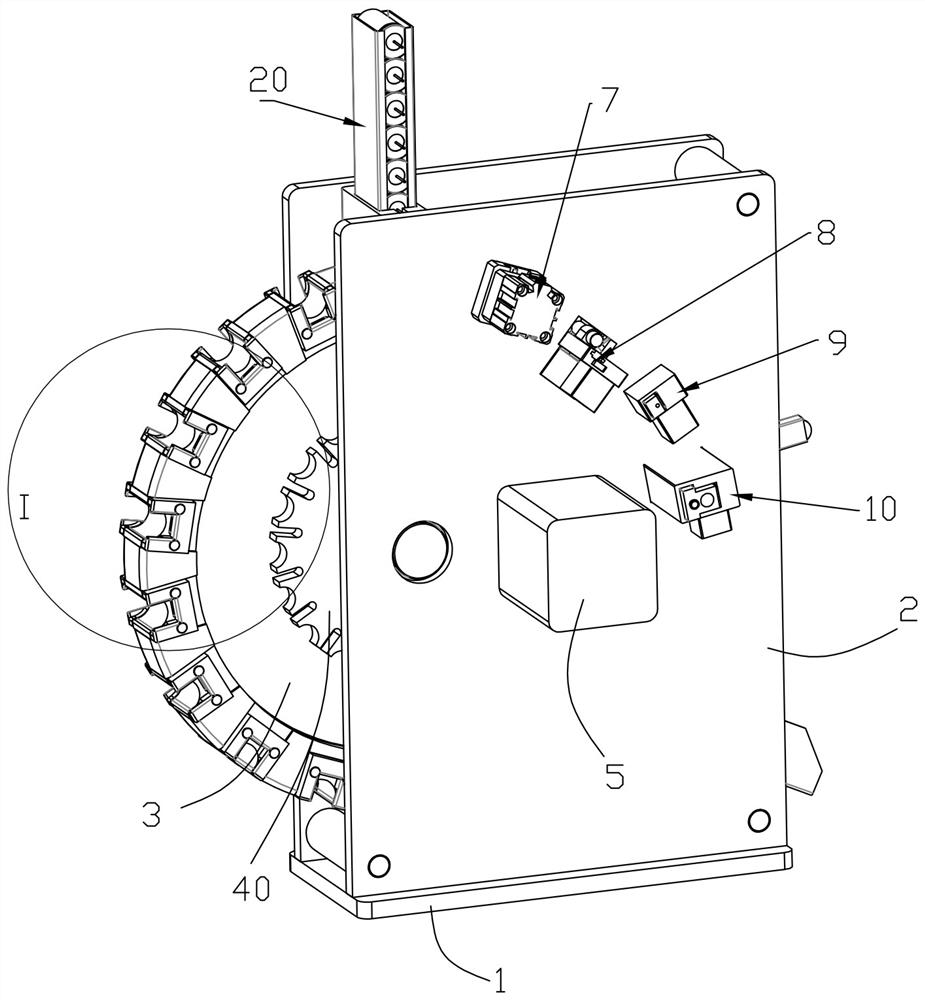

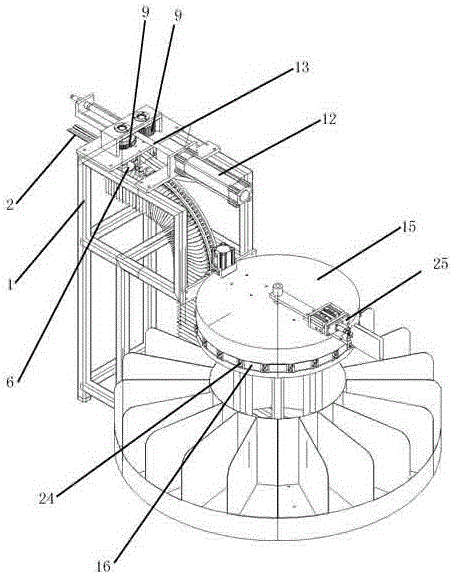

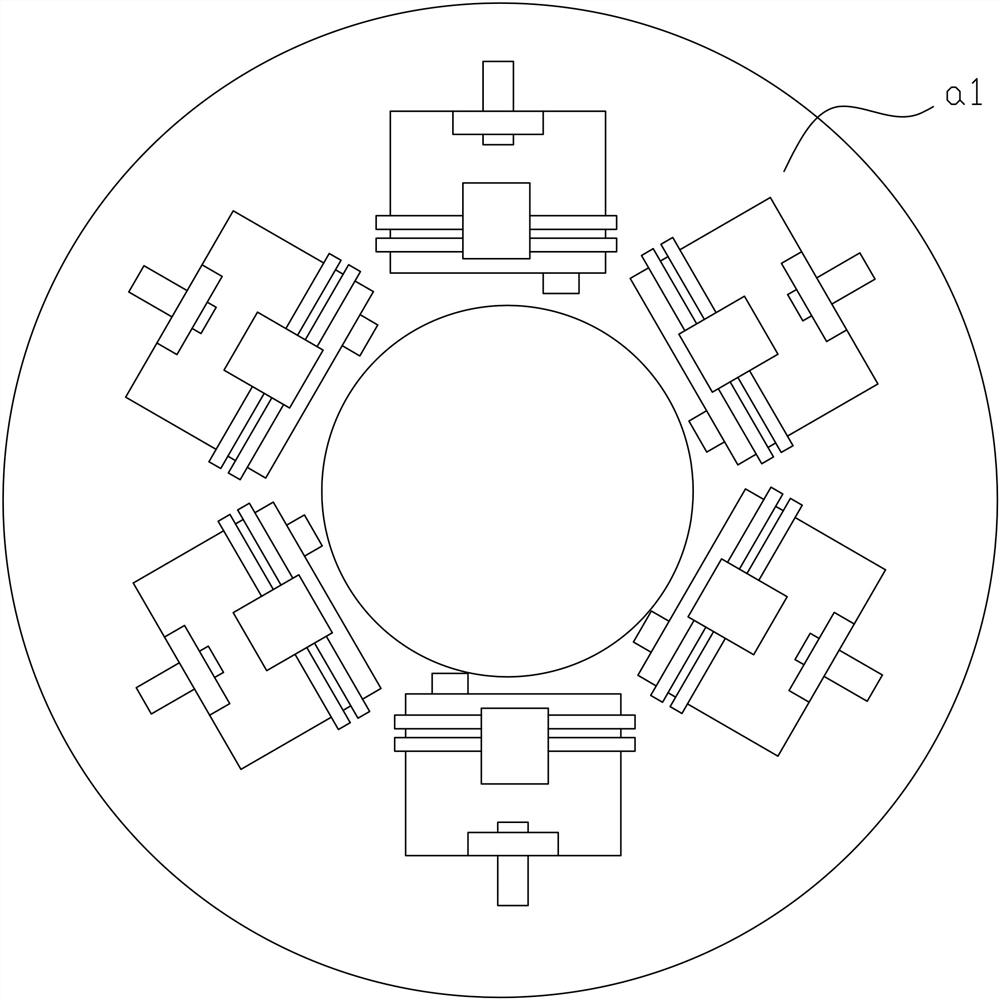

Intelligent rotary capacitor welding machine assembly line and welding method

ActiveCN111063554ARealize mechanized welding operationImprove welding efficiencyPrinted circuit assemblingTerminal applying apparatusAssembly lineCapacitor

The invention discloses an intelligent rotary capacitor welding machine assembly line and a welding method. A lead ball welding mechanism is used for carrying out ball head welding on leads on a capacitor, a gasket sleeving mechanism is used for sleeving the leads of the capacitor with insulating gaskets, and an electrode plate sleeving mechanism is used for sleeving the leads of the capacitor with electrode plates and welding the electrode plates and the leads together. Mechanical welding operation between the capacitor and the electrode plates can be achieved, the welding efficiency of the electrode plates is greatly improved, the product consistency is good, and the large-scale industrial production requirement is met.

Owner:陕西固德电子技术有限公司

Stable X-crystal-shaped agomelatine tablet and preparation method thereof

ActiveCN103655499ANo changeAdapt to the needs of large-scale industrial productionOrganic active ingredientsNervous disorderRoom temperaturePharmaceutic Adjuvant

The invention discloses a stable X-crystal-shaped agomelatine tablet and a preparation method thereof. The tablet is prepared by the following steps: selecting one or more protective agents, adding the protective agents in pure water, stirring, heating the mixture to 35-40 DEG C, dissolving until the solution is clear, cooling the solution to room temperature, adding X-crystal-shaped agomelatine, stirring the mixture uniformly, obtaining the protective agent containing the X-crystal shaped agomelatine, and keeping for standby use; mixing a part of pharmaceutic adjuvant uniformly, adding the protective agent containing the X-crystal-shaped agomelatine, mixing and pelletizing according to a wet method and drying to obtain particles containing the X-crystal-shaped agomelatine; at last, adding the other pharmaceutic adjuvants in the particles according to a proportion, mixing uniformly and tabletting. The preparation method can fully ensure that the crystal form of the X-crystal-shaped in the tablet preparation process is not changed; the stability between the X-crystal-shaped and the related substance is good to completely meet demand of large-scale production.

Owner:天津泰普制药有限公司

Stable crystalline form I agomelatine tablets and preparation method thereof

InactiveCN103690499AStir wellNo changeOrganic active ingredientsNervous disorderCrystallographyRoom temperature

Owner:TIANJIN TAIPU PHARMA SCI & TECH DEV

Stable crystalline form I agomelatine tablets and preparation method thereof

InactiveCN103690499BStir wellNo changeOrganic active ingredientsNervous disorderCrystallographyRoom temperature

The invention discloses stable crystalline form I agomelatine tablets and a preparation method thereof. The method comprises the following steps: adding one or several protective agents into purified water, stirring, heating to the temperature of 35-40 DEG C, dissolving until the mixture is clarified, cooling to room temperature, adding crystalline form I agomelatine, and uniformly stirring to obtain a protective agent containing the crystalline form I agomelatine; uniformly mixing partial pharmaceutical excipients, adding the protective agent containing the crystalline form I agomelatine, and performing wet mixed granulating and drying to obtain granules containing the crystalline form I agomelatine; finally, adding the rest pharmaceutical excipients for uniformly mixing according to a ratio, and tabletting. According to the preparation method, the condition that the crystalline form I is not changed in the tablet preparation process can be fully guaranteed; the stability of the crystalline form I and related substances is high, and the requirement of large-scale production can be completely met.

Owner:TIANJIN TAIPU PHARMA SCI & TECH DEV

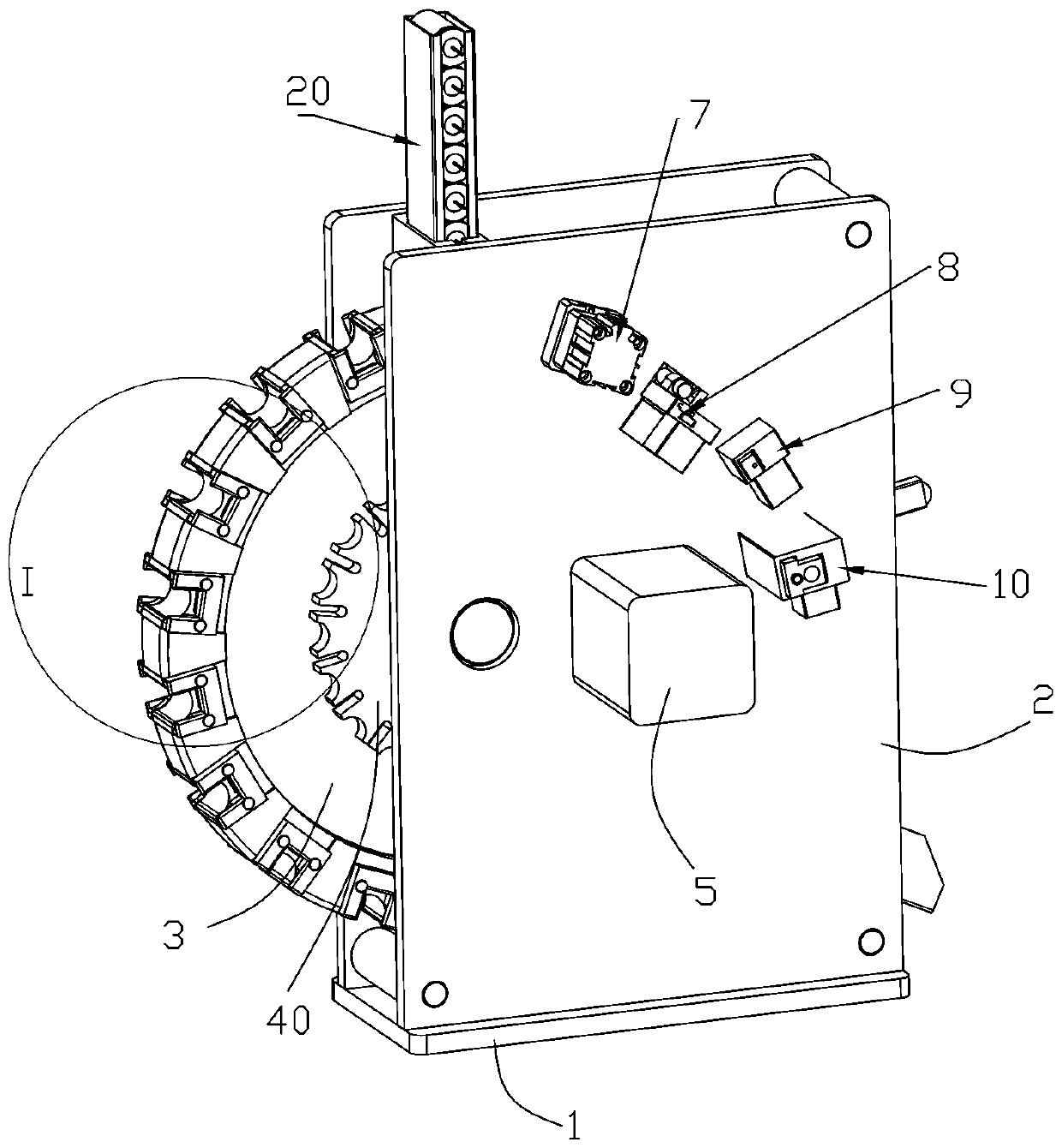

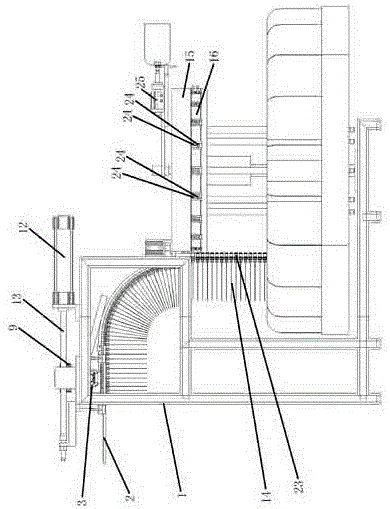

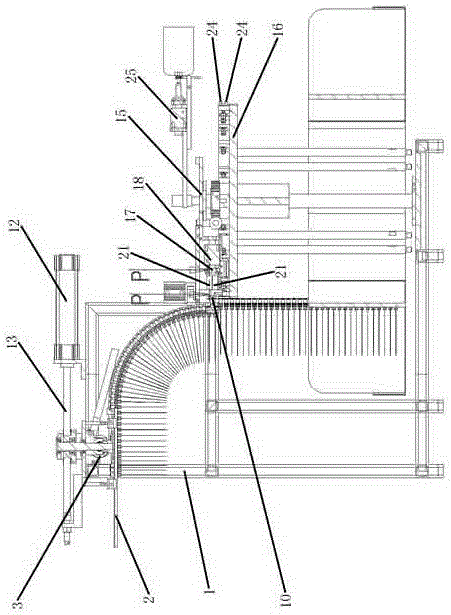

An intelligent rotary capacitor welding robot equipment

ActiveCN111063551BRealize mechanized welding operationImprove welding efficiencyTerminal applying apparatusMetal working apparatusElectric machineEngineering

The invention is a kind of intelligent rotary capacitor welding robot equipment, which discloses a rotary capacitor welding equipment, which includes a bottom plate, a vertical plate, a turntable, a fixture installation ring and a first motor, and the ring wall of the fixture installation ring is equally spaced Several electromagnetic clamping mechanisms are fixed, and the two vertical plates are respectively symmetrically provided with a lead wire cutting mechanism, a lead wire ball welding mechanism, a gasket sleeve mechanism, and an electrode sheet sleeve welding mechanism along the rotation direction of the turntable. The lead cutting mechanism is used to cut off the redundant lead part on the capacitor, the lead ball welding mechanism is used to perform ball welding on the lead wire on the capacitor, and the gasket sleeve mechanism is used to sleeve the insulating gasket into the capacitor On the lead, the electrode piece welding mechanism is used to put the electrode piece on the lead of the capacitor and weld the electrode piece and the lead wire together. The invention can realize the mechanized welding operation between the capacitor and the electrode sheet, greatly improves the welding efficiency of the electrode sheet, has good product consistency, and meets the needs of large-scale industrial production.

Owner:象山永光机械制造有限公司

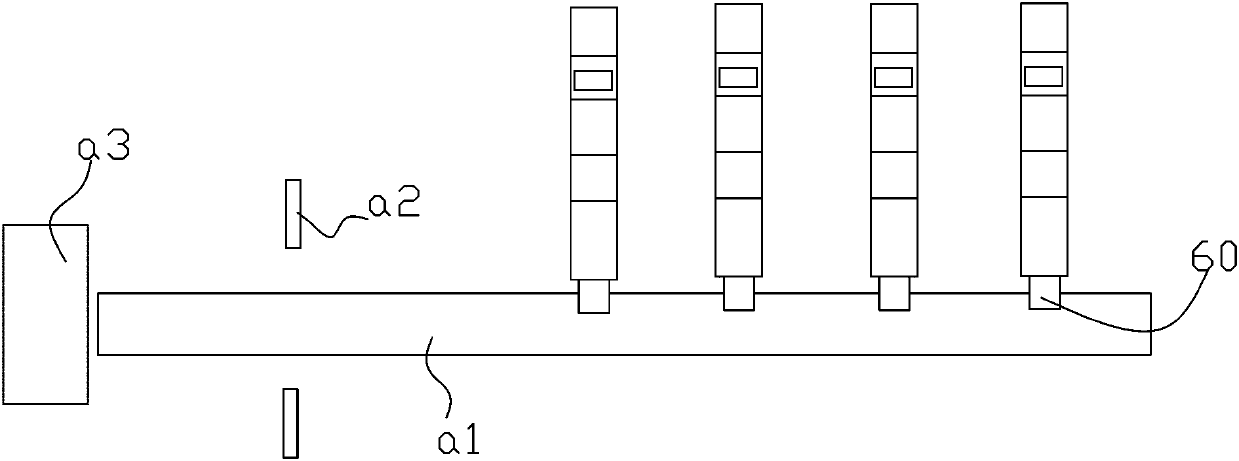

The bag feeding mechanism of the filling machine

ActiveCN103879591BImprove work efficiencyAdapt to the needs of large-scale industrial productionPackagingTube drawingEngineering

A bag feeding mechanism of a filling machine comprises a rack, wherein a tube drawing mechanism is installed on the rack, the tube drawing mechanism comprises a filling drinking tube positioning slide groove, a serial-connection sheet stripping mechanism, a tube clamping and feeding mechanism and a driving mechanism, wherein the filling drinking tube positioning slide groove can make outlet segments of filling drinking tubes of packaging bags slide along the groove and limit the outlet segments in the groove, the serial-connection sheet stripping mechanism is used for stripping serial-connection sheets for sorting packaging bags off the filling drinking tubes, the tube clamping and feeding mechanism is used for clamping the filling drinking tubes of the packaging bags and pushing the filling drinking tubes of the packaging bags forwards along the filling drinking tube positioning slide groove, and the driving mechanism drives the serial-connection sheet stripping mechanism and the tube clamping and feeding mechanism to rotate. The bag feeding mechanism has the advantages that the serial-connection sheets for sorting the packaging bags can be automatically stripped off the filling drinking tubes through the tube drawing mechanism, the filling drinking tubes are pushed to move forwards along the filling drinking tube positioning slide groove, the serial-connection sheets for sorting the packaging bags can be sequentially connected in series through a sheet connecting mechanism, so that the tube drawing mechanism can work conveniently, the working efficiency of the whole bag feeding mechanism is high, and the bag feeding mechanism can adapt to requirements for large-scale industrial production.

Owner:SHANTOU HONGQIAO PACKAGING IND CO LTD

Barium chloride production technology

InactiveCN101654274BReduce in quantityReduce wasteCalcium/strontium/barium chloridesAxial-flow pumpBarium salt

The invention discloses a technology for producing barium chloride by the witherite containing barium carbonate, which mainly comprises steps as follows: sulfur iron impurities are decomposed and oxidated to remove and the hydrated barium salt raw material liquid is prepared; the raw material liquid is electrically heated and concentrated in vacuum, which is driven by an axial flow pump, the solute is thermally crystallized to form the hydrated barium chloride dihydrate saturated crystalline; the crystallized hydrate is cooled to produce the serial barium salt products, wherein the vacuum heating condensation crystallization is a continuous production process; the whole technological process is implemented in the closed state; the by-products could be recycled; the crystallisation processis completed at one time and the production process is continuous. The products manufactured in the technological process has low impurity content, saves energy, is adaptive to the large-scale industrialization production and reduces the pollution and resource waste to a large extent.

Owner:重庆洋铭化工产品有限公司

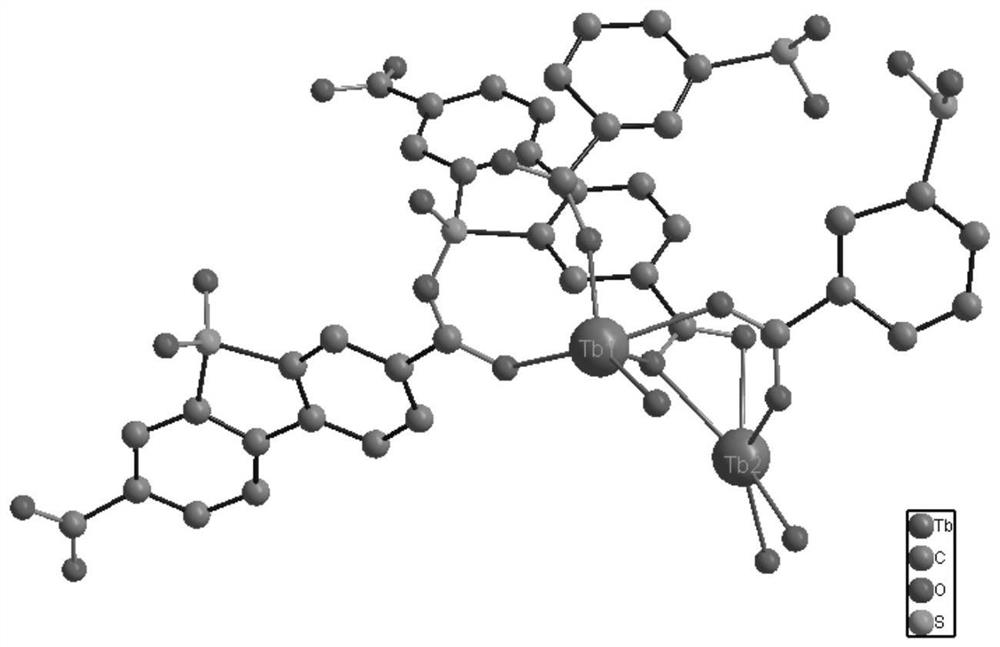

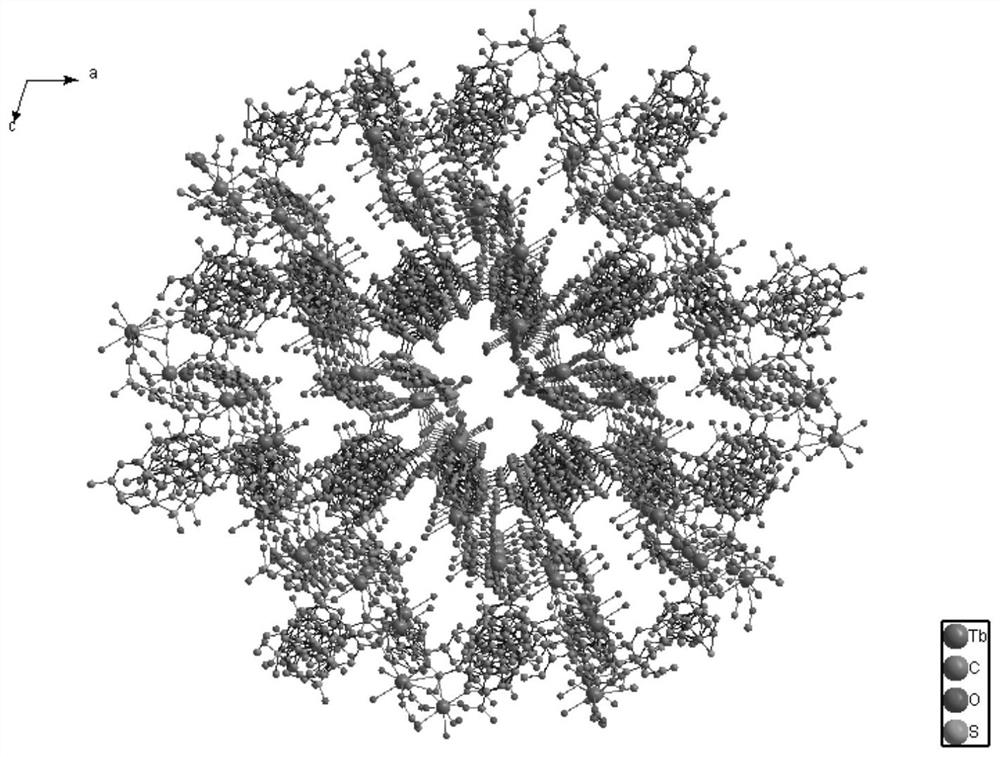

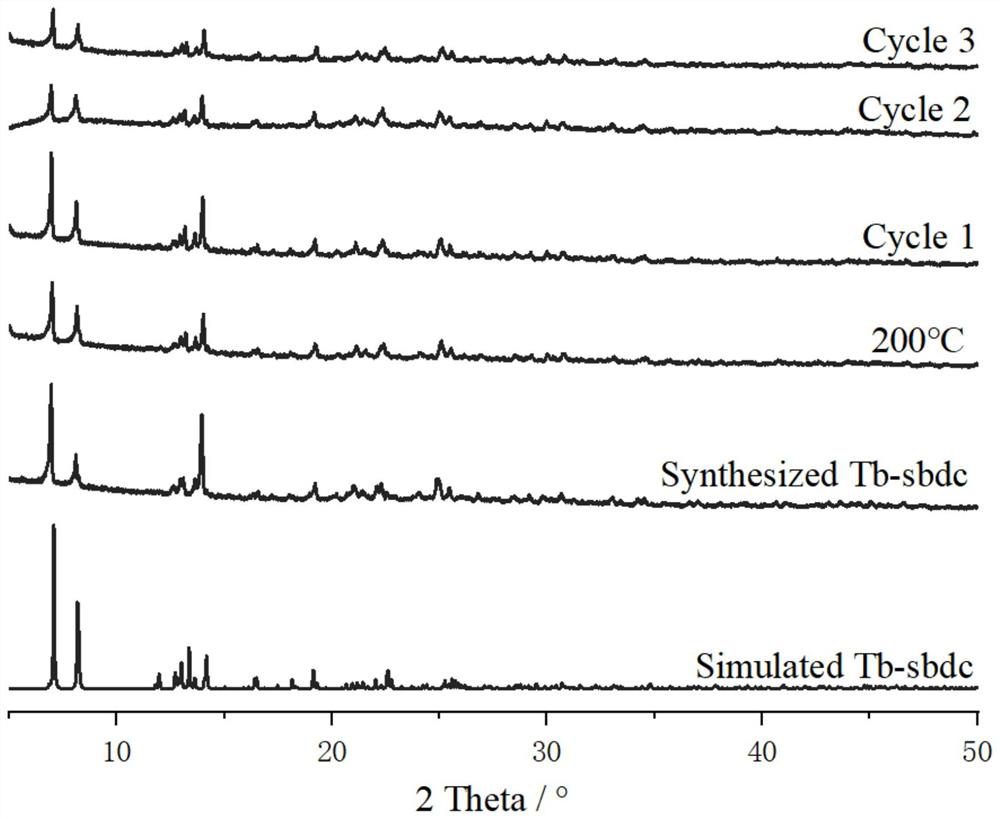

Preparation method and application of dibenzothienyl lanthanide metal organic framework compound

PendingCN114262448AThe synthesis method is simpleEasy to operateGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsMetal-organic frameworkPerylene derivatives

The invention belongs to the technical field of catalytic materials, and relates to a preparation method and application of a dibenzothienyl lanthanide metal organic framework compound, and the preparation method comprises the following steps: taking dibenzo [b, d] thiophene-2, 8-dicarboxylic acid-5, 5-dioxide H2sbdc in a dibenzothiophene derivative as a linking ligand, and carrying out one-step reaction to obtain the dibenzothienyl lanthanide metal organic framework compound. And preparing the dibenzothienyl lanthanide metal organic framework compound Tb-sbdc with a pore channel structure by taking Tb < 3 + > in lanthanide metal salt as a node through a hydrothermal synthesis method. According to the present invention, the catalyst synthesis method is simple, the practical operation is simple, the catalyst and the raw materials for the catalytic reaction are low in price, the reaction yield is high, and the obtained functional material has characteristics of thermal stability and chemical stability, easy large-area promotion and application, adaptation to the requirements of large-scale industrial production, and good industrial prospect.

Owner:DALIAN UNIV OF TECH

Smart and compact automated capacitor welding robot

InactiveCN111029176BReduce labor costsImprove consistencyWelding/soldering/cutting articlesTerminal applying apparatusCapacitorWelding process

The invention discloses an intelligent and compact automatic capacitor welding robot, which comprises a bottom plate, two support plates, a top plate, a capacitor feeding device fixedly connected to the top plate, a linear slide table fixed on the top plate, and a capacitor feeding device fixedly connected The laser line cutting device on the top also includes ball welding devices, gasket sleeve devices and electrode sheet sleeve welding devices symmetrically located on both sides of the capacitor feeding device. The linear slide table is used to simultaneously drive the ball welding devices on both sides of the capacitor feeding device, The gasket socketing device and the electrode sheet welding device complete the ball welding process, the insulating sheet socketing process, and the electrode sheet welding process for the capacitor in sequence; the invention can automatically realize the welding work between the capacitor and the electrode sheet, which greatly saves labor costs , to provide the welding efficiency of capacitors, good product consistency, adapt to the needs of large-scale industrial production, and compact structure, light weight, good portability, suitable for use in occasions where the workplace is frequently changed.

Owner:张美蓉

Intelligent compact automatic capacitor welding robot

InactiveCN111029176AReduce labor costsGood consistencyWelding/soldering/cutting articlesTerminal applying apparatusLaser cuttingElectrical and Electronics engineering

The invention discloses an intelligent compact type automatic capacitor welding robot comprising a bottom plate, two supporting plates, a top plate, a capacitor feeding device fixedly connected to thetop plate, a linear sliding table fixed to the top plate, and a laser cutting device fixedly connected to the capacitor feeding device. The intelligent compact type automatic capacitor welding robotalso comprises ball bonding devices, gasket sleeve joint devices and electrode plate sleeve welding devices which are symmetrically arranged on the two sides of the capacitor feeding device. The linear sliding table is used for simultaneously driving the ball bonding devices, the gasket sleeve devices and the electrode plate sleeve welding devices on the two sides of the capacitor feeding device to sequentially complete a ball bonding procedure, an insulating sheet sleeve procedure and an electrode plate sleeve welding procedure on the capacitor. The welding work between the capacitor and theelectrode plate can be automatically achieved, the labor cost is greatly saved, the welding efficiency of the capacitor is improved, the product consistency is good, the large-scale industrial production requirement is met, and the robot is compact in structure, light in weight, good in portability and suitable for being used in occasions where working places are frequently replaced.

Owner:张美蓉

Intelligent and compact automatic capacitor welding robot and welding method

ActiveCN111014992BReduce labor costsImprove consistencyCapacitor manufactureWelding apparatusCapacitorElectrical and Electronics engineering

The invention discloses an intelligent and compact automatic capacitor welding robot and a welding method. The linear sliding table is used to simultaneously drive the ball welding device on both sides of the capacitor feeding device, the gasket sleeve device and the electrode piece sleeve welding device to complete the ball welding of the capacitor in sequence. Sequence, insulating gasket socketing process, and electrode sheet welding process; the invention can automatically realize the welding work between the capacitor and the electrode sheet, greatly saving labor costs, improving the welding efficiency of the capacitor, good product consistency, and adapting to large-scale It is required for industrial production, and has a compact structure, light weight, and good portability, and is suitable for use in occasions where the workplace is frequently changed.

Owner:DEZHOU KASRY CNC TECH CO LTD

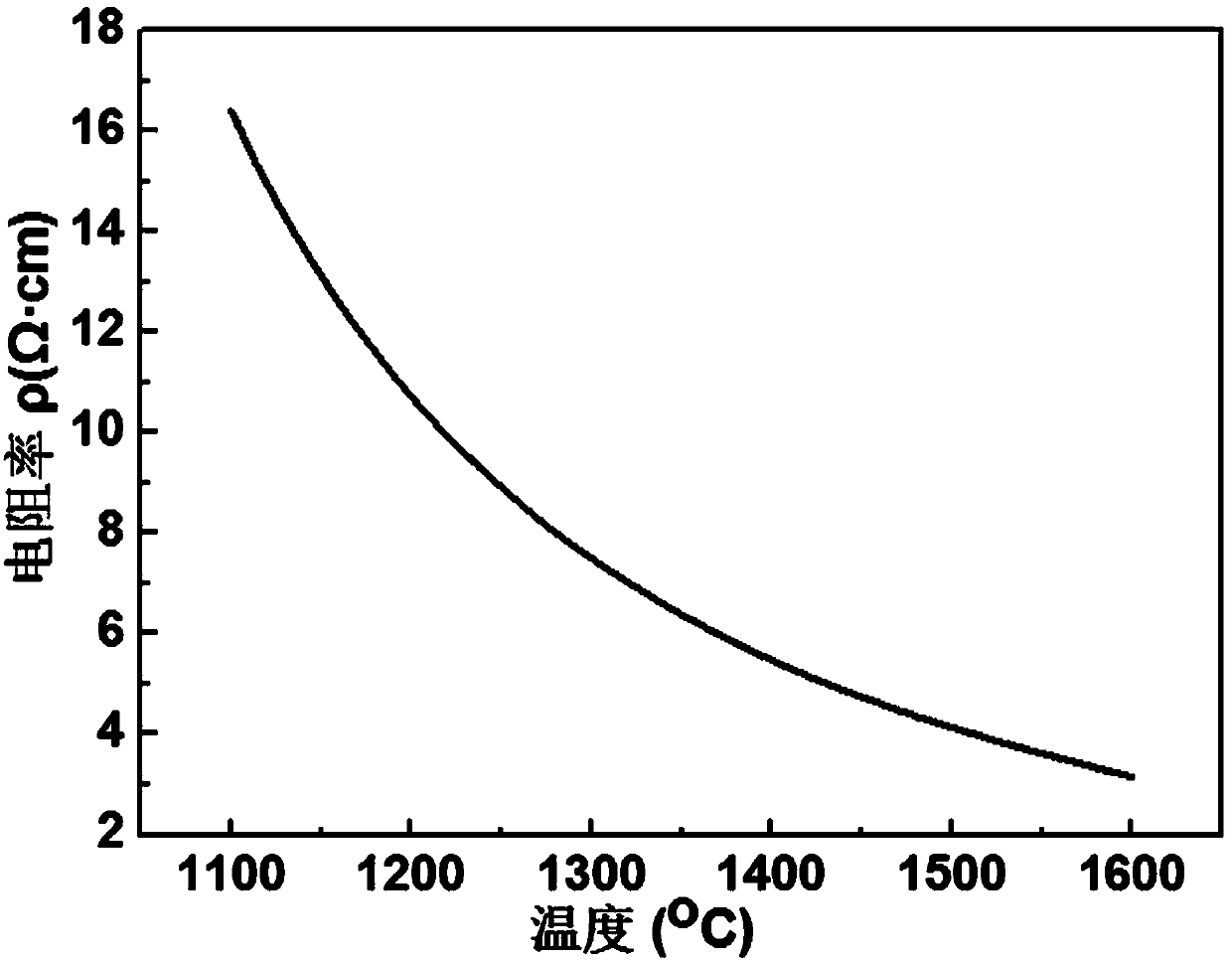

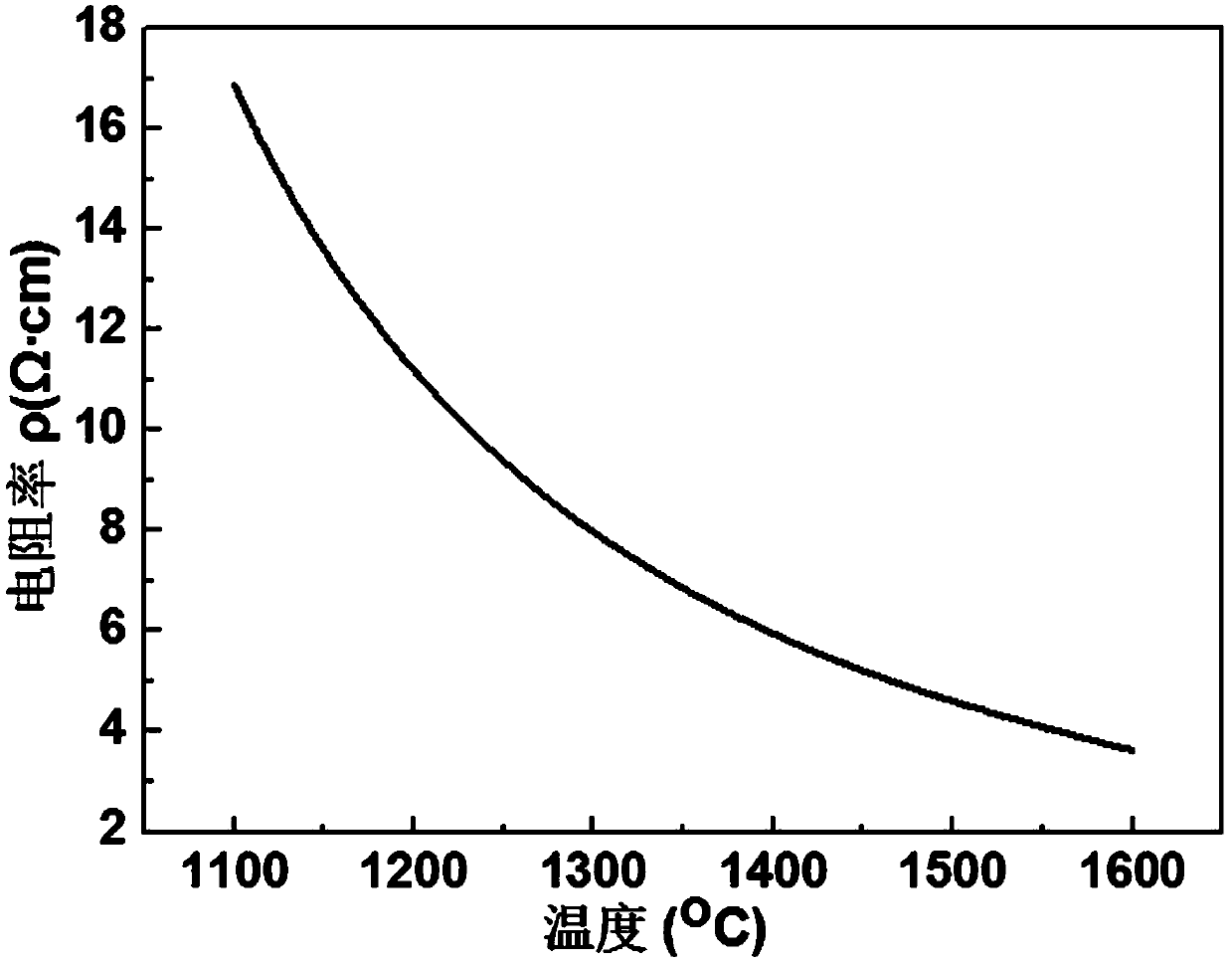

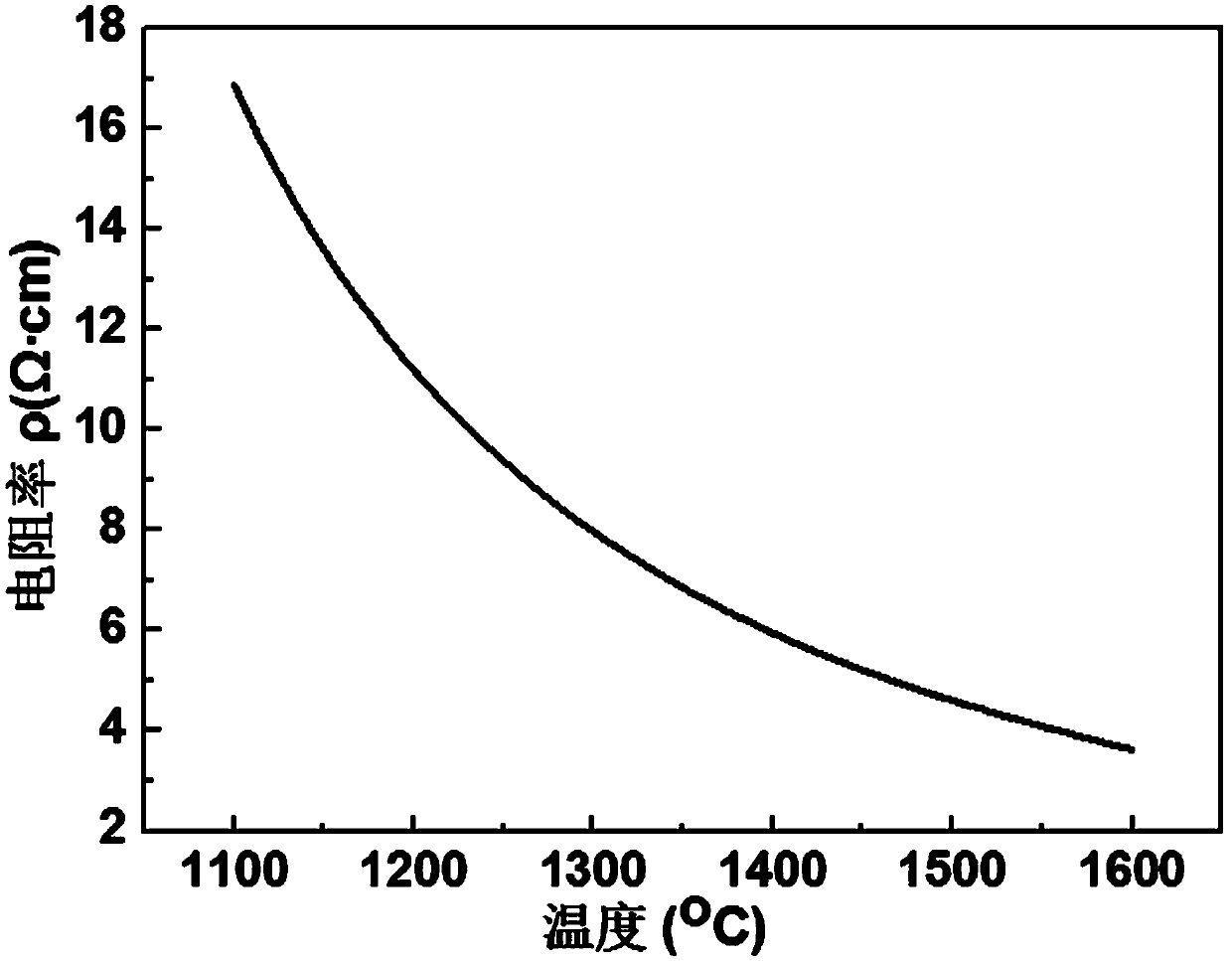

A high strain point aluminosilicate glass with high electrical resistance properties

ActiveCN107986618BGood clarificationImprove high temperature resistanceHigh resistanceArchitectural glass

The invention relates to high-strain-point aluminosilicate glass with high resistance properties. The aluminosilicate glass is prepared from the following components in mass percent: 55%-75% of a glass former oxide, 5%-22% of a network intermediate oxide and 9.1%-57.5% of an electrical property enhancer, wherein the electrical property enhancer is a mixture of a monovalent alkali metal, a divalentalkaline earth metal, a tetravalent oxide and a rare earth oxide. The glass provided by the invention has the advantages that the glass has higher resistance properties, can adapt to an electric smelting process, has high thermodynamic properties such as high product strain point, meets requirements of large-scale industrial production, has a good visual effect, can be well applied to thin film solar cells, electronic information display and building glass, has higher mechanical properties, is suitable for working under bad conditions, and improves the safety in use.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Cup conveyor belts for sheet forming machines

The invention discloses a receiving cup conveying belt of a sheet forming machine, and relates to a sheet forming machine, which comprises a belt conveying mechanism and is characterized by also comprising a product hoisting and transferring mechanism, wherein the belt conveying mechanism comprises a rack, a driving mechanism, a driving wheel, a driven wheel and at least two mutually parallel conveying belts, the driving wheel and the driven wheel are respectively fixed on the rack in a rotatable mode, each conveying belt is respectively sleeved on the driving wheel and the driven wheel, the driving mechanism is connected with the driving wheel, and the product hoisting and transferring mechanism is fixed on the rack and is positioned between the driving wheel and the driven wheel and at the inner side of each conveying belt. According to the conveying belt disclosed by the invention, the situation of product toppling-over is effectively avoided, so that the number of products conveyed by the transferring mechanism every time can be greatly increased, the working efficiency is effectively improved, and the need of large-scale industrial production can be met.

Owner:大连达诚环保机械有限公司

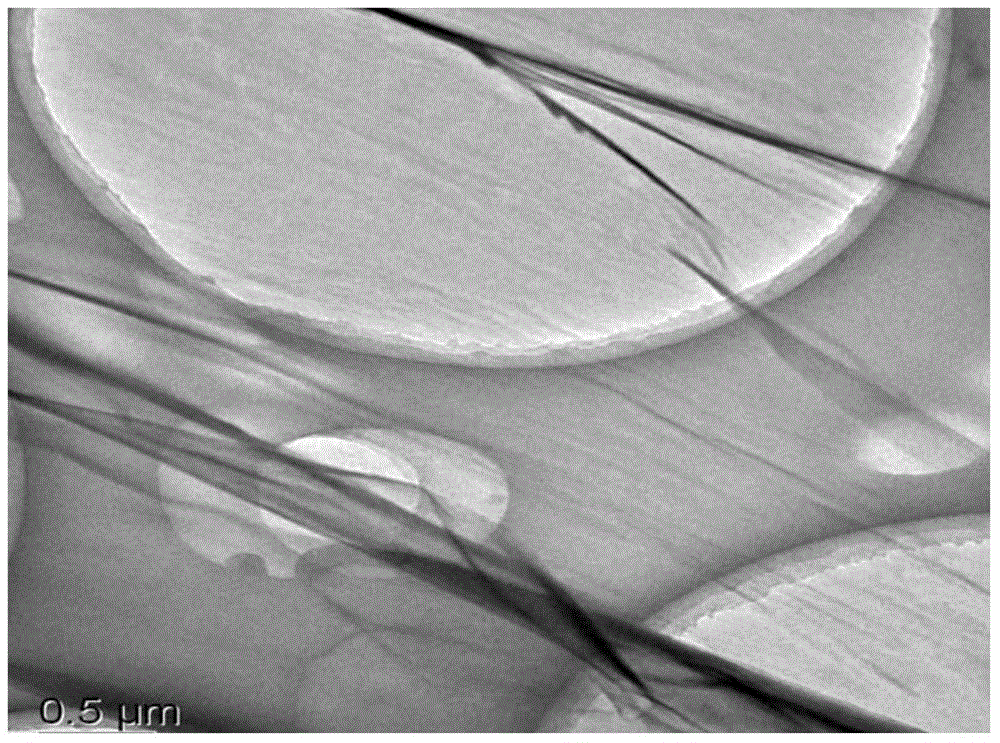

Superhigh water-soluble functionalized graphene/oxidized graphene and preparation method thereof

Owner:抚州鳌系新材料有限公司

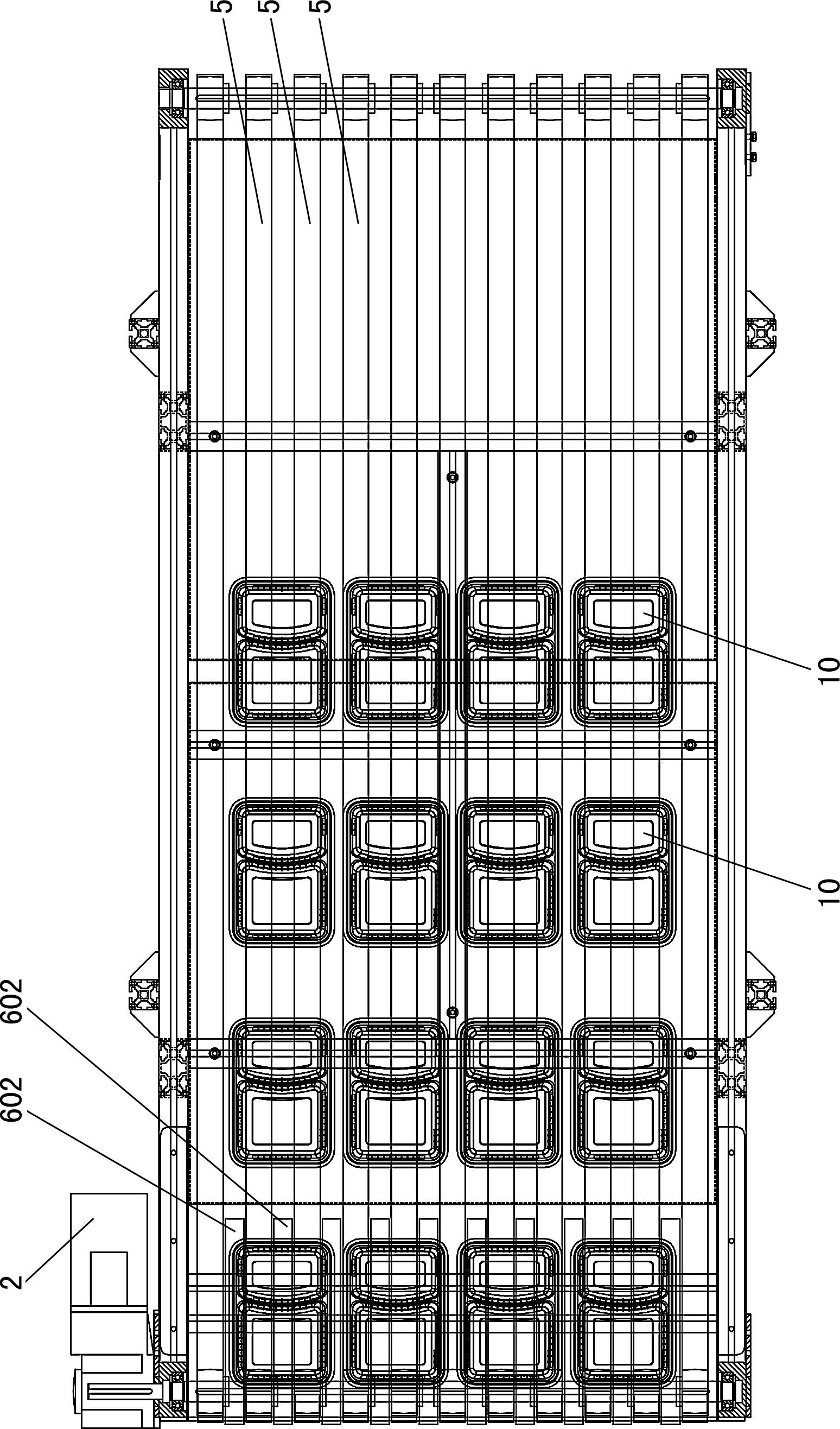

Loading system for plasma etcher

InactiveCN103219218BRealize continuous automatic etchingIncrease productivityElectric discharge tubesEngineeringManipulator

A plasma etcher loading system comprises a loading cavity body and a cavity cover, a sealing ring is arranged between the loading cavity body and the cavity cover, a manipulator sheet taking and sending opening is formed in one side of the loading cavity body, a gate valve is arranged in the sheet taking and sending opening and connected with a manipulator cavity body, the loading cavity body is connected with a vacuum mechanical pump and an external air source, a tray rack of a supporting sheet tray is arranged inside the loading cavity body, the tray rack is provided with a plurality of supporting positions of the supporting sheet tray, each supporting position is provided with a notch which allows the sheet tray to leave, the tray rack is fixed on a base frame which is connected with a lifting rotating device, the lifting rotating device comprises a lifting operation portion and a rotating operation portion, the lifting operation portion comprises a guide rod, a lifting motor and a lifting transmission mechanism, the rotating operation portion comprises a rotating motor and a rotating transmission mechanism which is used for connecting the guide rod with the rotating motor, and a gap between the guide rod and the cavity body is sealed. The plasma etcher loading system has the advantages of being large in productivity of the sheet tray and capable of achieving batch machining.

Owner:TDG MACHINERY TECH

A kind of polyurethane and foamed cement micro-composite thermal insulation material and preparation method thereof

ActiveCN106565167BComposite interface stabilityGood weather resistanceCeramicwarePolyolRoom temperature

The invention provides a polyurethane and foamed cement microscopically-composite heat insulating material and a preparation method therefor and belongs to the field of organic / inorganic composite type building materials. The preparation method is characterized by comprising the steps: adding ingredients such as cement and a foam stabilizer according to the conventional method, preparing foamed cement through carrying out foaming with hydrogen peroxide, and then, carrying out room-temperature curing until the foamed cement reaches an age; and then, mixing isocyanate, polyether polyol, polysiloxane polyether and a catalyst so as to obtain uniform slurry, then, submerging the dried foamed cement in the slurry, taking out the foamed cement after the foamed cement is completely impregnated with the slurry, carrying out standing for 2 to 4 hours so as to cure the foamed cement, then, submerging the foamed cement in water again, and then, carrying out foaming in a manner that water molecules are in contact with incompletely-reacted isocyanate through diffusion and infiltration, thereby obtaining the microscopically-composite heat insulating material. According to the material, organic polyurethane foam and inorganic cement foam are mutually independent and coexist in an interpenetrating manner, and microscopic compounding among interfaces is achieved, so that the foamed cement has relatively high compressive strength and relatively low coefficient of thermal conductivity.

Owner:CENT SOUTH UNIV

Bag threading device

ActiveCN103879758BImprove work efficiencyAdapt to the needs of large-scale industrial productionConveyor partsEngineeringMechanical engineering

The invention relates to a threading device of packaging bags. The threading device comprises a rack and is characterized in that a filling drinking pipe locating sliding groove, a bunched sheet conveying mechanism, a clamping pressing pipe mechanism and a driving mechanism are arranged on the rack, wherein filling drinking pipe outlet sections of the packaging bags are limited in a groove in the mode of being capable of sliding along the groove through the filling drinking pipe locating sliding groove, the bunched sheet conveying mechanism is used for conveying packaging bag tidying bunched sheets, the clamping pressing pipe mechanism is used for clamping filling drinking pipes of the packaging bags, tidying a neck and pressing the filling drinking pipes into tidying locating holes of the packaging bag tidying bunched sheets, the driving mechanism respectively drives the bunched sheet conveying mechanism and the clamping pressing pipe mechanism to rotate, the clamping pressing pipe mechanism is located below the filling drinking pipe locating sliding groove, and the bunched sheet conveying mechanism is located below the clamping pressing pipe mechanism. The threading device of the packaging bags has the advantages that the bunched sheet conveying mechanism is matched with the clamping pressing pipe mechanism, the work that the multiple packaging bags are sequentially arranged and bunched on the packaging bag tidying bunched sheets can be automatically completed, the working efficiency is high, and the threading device can be suitable for large-scale industrial production requirements.

Owner:SHANTOU HONGQIAO PACKAGING IND CO LTD

A kind of production method of water-based polyurethane synthetic leather

ActiveCN104695236BImprove processing stabilityIncrease productivityLamination ancillary operationsLaminationWater basedWorking environment

The invention relates to a method for manufacturing water-based polyurethane synthetic leather. The designed technological process comprises the steps of preparing base fabric, humidifying and arranging the base fabric, coating water-based sizing agent, acid-releasing, solidifying, forming, washing, drying and sizing. The method has the advantages that no solvent is added, the organic contamination is thoroughly eliminated from the source, the potential safety hazards are eliminated, the working environment of workers is improved, and green and environment protective cleaning production is achieved indeed; the performances of a product is close to or superior to those of a solvent type product in appearance, structure, hand feeling and physical property, and the product is the best substitute for the solvent type product as well as a mainstream product of synthetic leather field development in the future.

Owner:HUADA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com