Full-automatic cup piling machine

A cup stacking machine, a fully automatic technology, applied in the stacking, transportation and packaging of objects, can solve the problems of inability to meet large-scale industrial production, easy overturning of cup stacks, restrictions on the number and height of plastic cups, etc. Good, error-prone, hygienic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

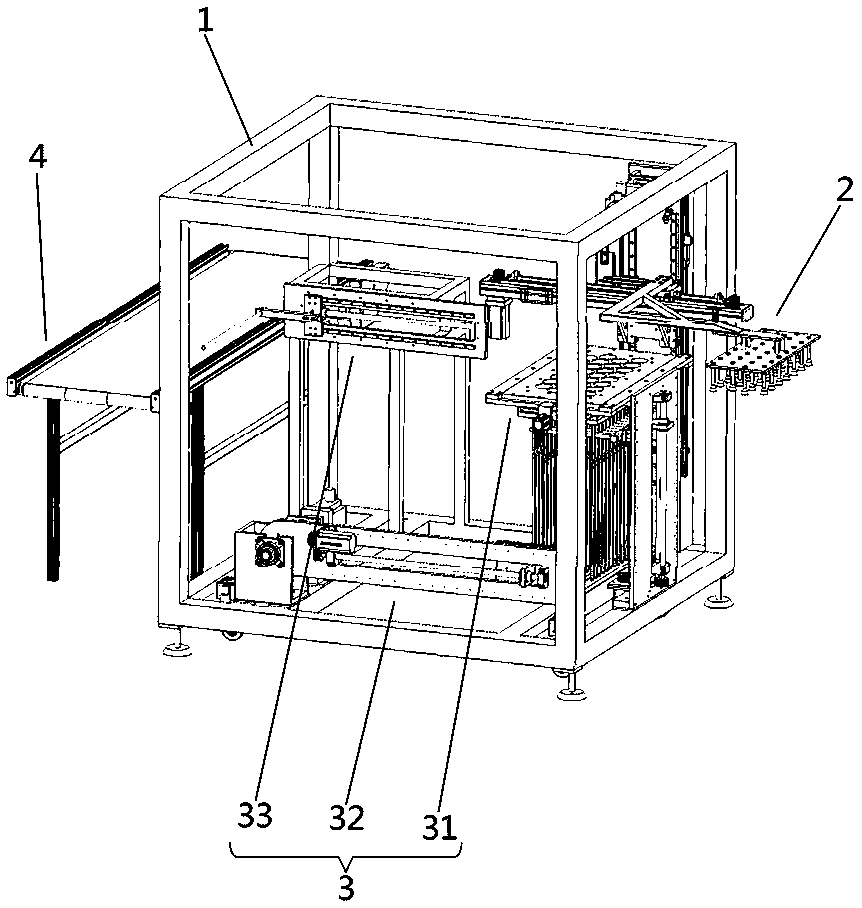

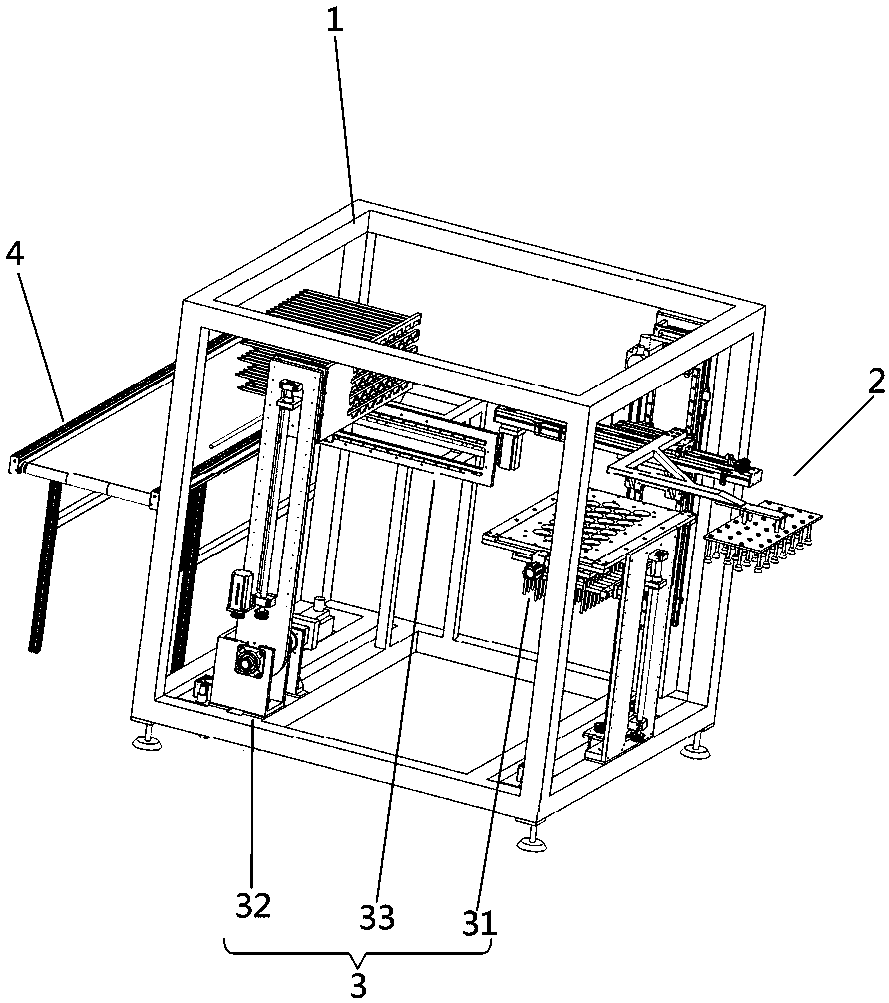

[0041] Such as Figure 1-13 As shown, the fully automatic cup stacking machine in this preferred embodiment includes a frame 1, a plastic cup grasping and placing mechanism that grabs the plastic cups on the molding mold and transfers the plastic cups, receives the plastic cups and stacks the plastic cups successively into The plastic cup stacking device 3 that stacks the cups and pushes them out, the finished product conveying mechanism 4 that receives the cup stacks and sends them out sequentially, the plastic cup pick and place mechanism, the plastic cup stacking device 3, and the finished product conveying mechanism 4 are installed on the frame 1 respectively.

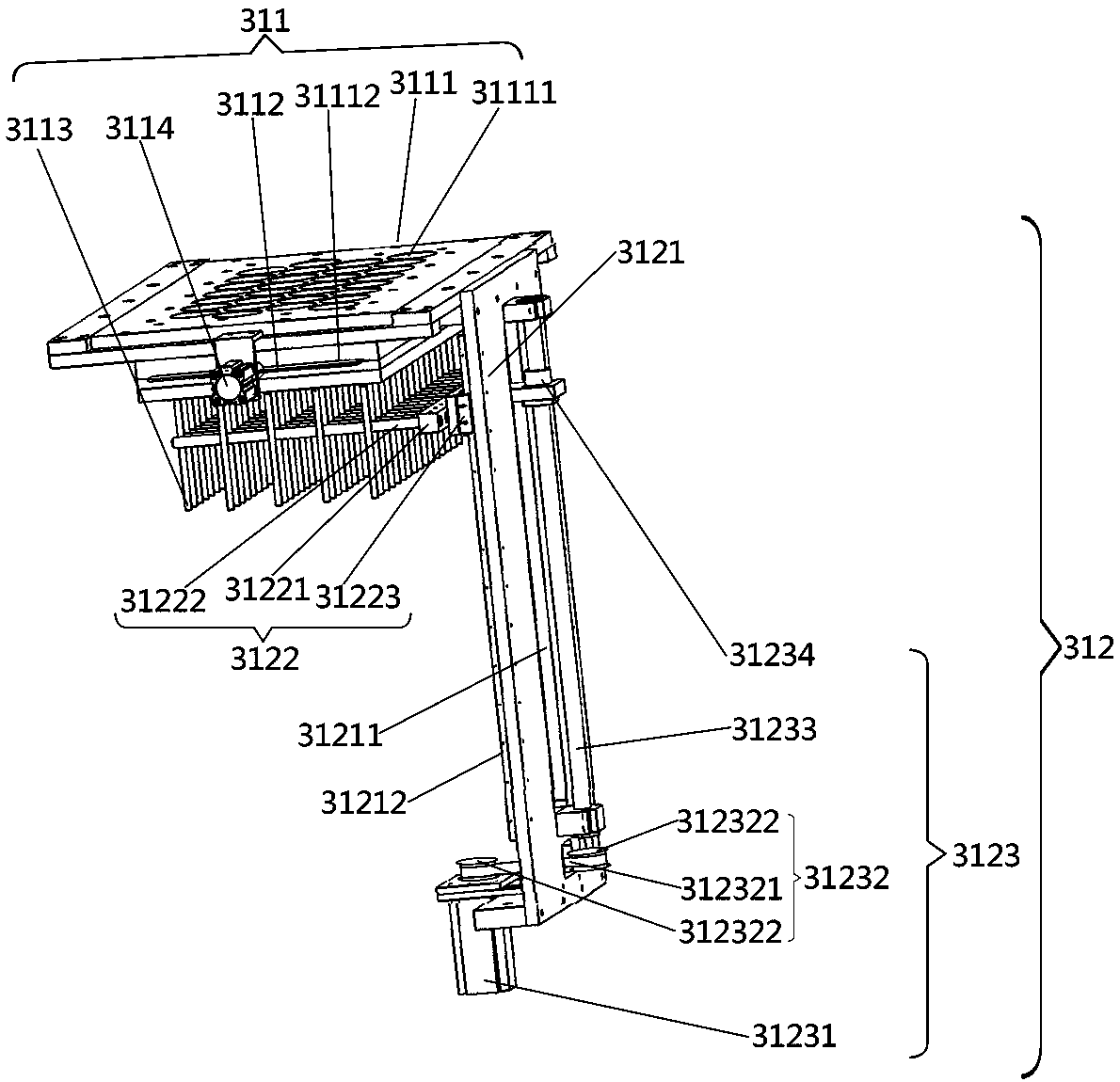

[0042] The plastic cup stacking device 3 includes a cup stacking mechanism 31 that receives and stacks the plastic cups transferred by the plastic cup pick-and-place mechanism, collects the plastic cups stacked by the cup stacking mechanism 31 to obtain a complete cup stack, and sends the plastic cups above the fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com