A mold for integral sealing of multi-bottle bodies and a packaging method using the same

A technology of overall sealing and bottle body, which is applied in the direction of packaging sealing/fastening, packaging, wrapping paper, etc., can solve the problem of easy entry of a large amount of dust, etc., achieve the effect of simple packaging method, simple mold structure, and hygienic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

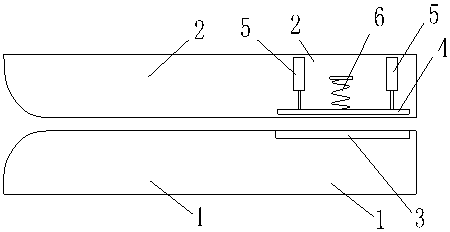

[0026] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present embodiment provides a mold for integral sealing of multi-bottle bodies, including two first side plates 1 arranged parallel to each other and facing each other, the upper end surfaces of the two first side plates 1 are flush, and each first A second side plate 2 is correspondingly arranged directly above the side plate 1, and the lower end surfaces of the two second side plates 2 are flush with each other, and the upper end surface of the first side plate 1 is aligned with the lower end surface of the second side plate 2 above it. Parallel, and the distance between the first side plate 1 and the corresponding second side plate 2 is 2cm, the outer sides of the two first side plates 1 are respectively provided with a heat-sealing press plate 3, and the top of the heat-sealing press plate 3 is correspondingly provided with The heat-sealing knife 4 is parallel to the corresponding heat-sealing platen 3,...

Embodiment 2

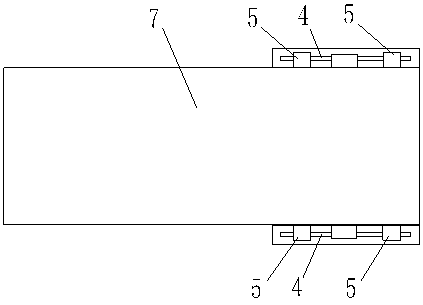

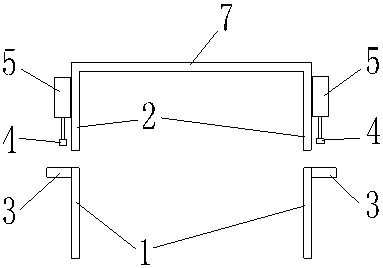

[0031] refer to figure 1 , Figure 5 and Figure 6 , Figure 5 The arrows in the figure point to the direction of the bottle packaging. This embodiment provides a mold for integral sealing of multiple bottles, including two first side plates 1 parallel to each other and facing each other. The two first side plates 1 The upper end surfaces of the two second side plates 2 are flush with each other, and a second side plate 2 is correspondingly arranged directly above each first side plate 1, and a top plate 7 is also provided on the upper ends of the two second side plates 2, and the two second side plates 2 The upper end of the top plate 7 is an integral structure, the lower end surfaces of the two second side plates 2 are flush, the upper end surfaces of the first side plate 1 are all parallel to the lower end surfaces of the second side plate 2 above it, and the first side plate The distance between 1 and the corresponding second side plate 2 is 4cm, and the outer sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com