Full automatic edge cutter of plant fibre moulding article

A technology of plant fibers and molded products, applied in metal processing, etc., can solve problems such as unhygienic, unsafe, and low product efficiency, and achieve the effects of ensuring hygienic conditions, improving production efficiency, and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

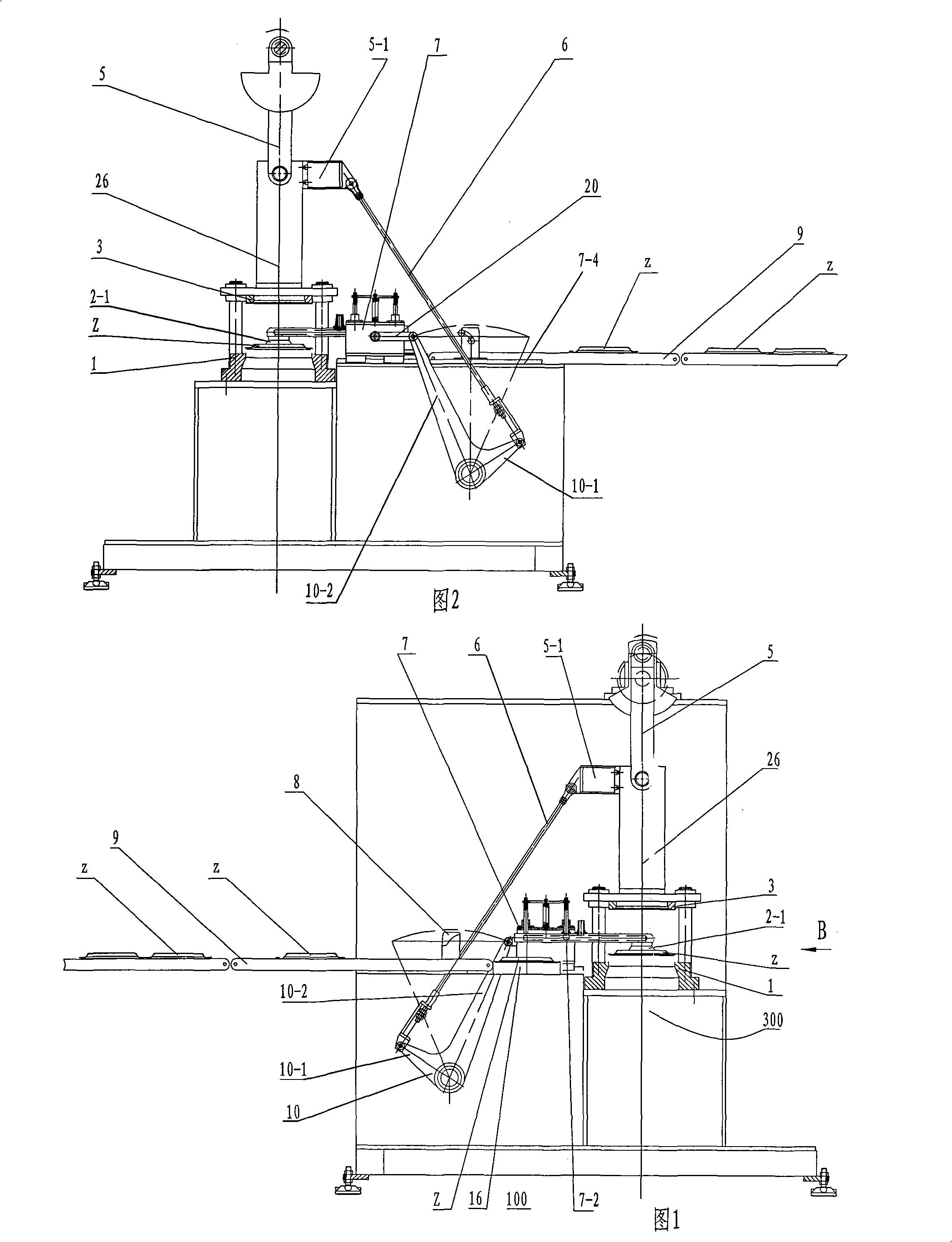

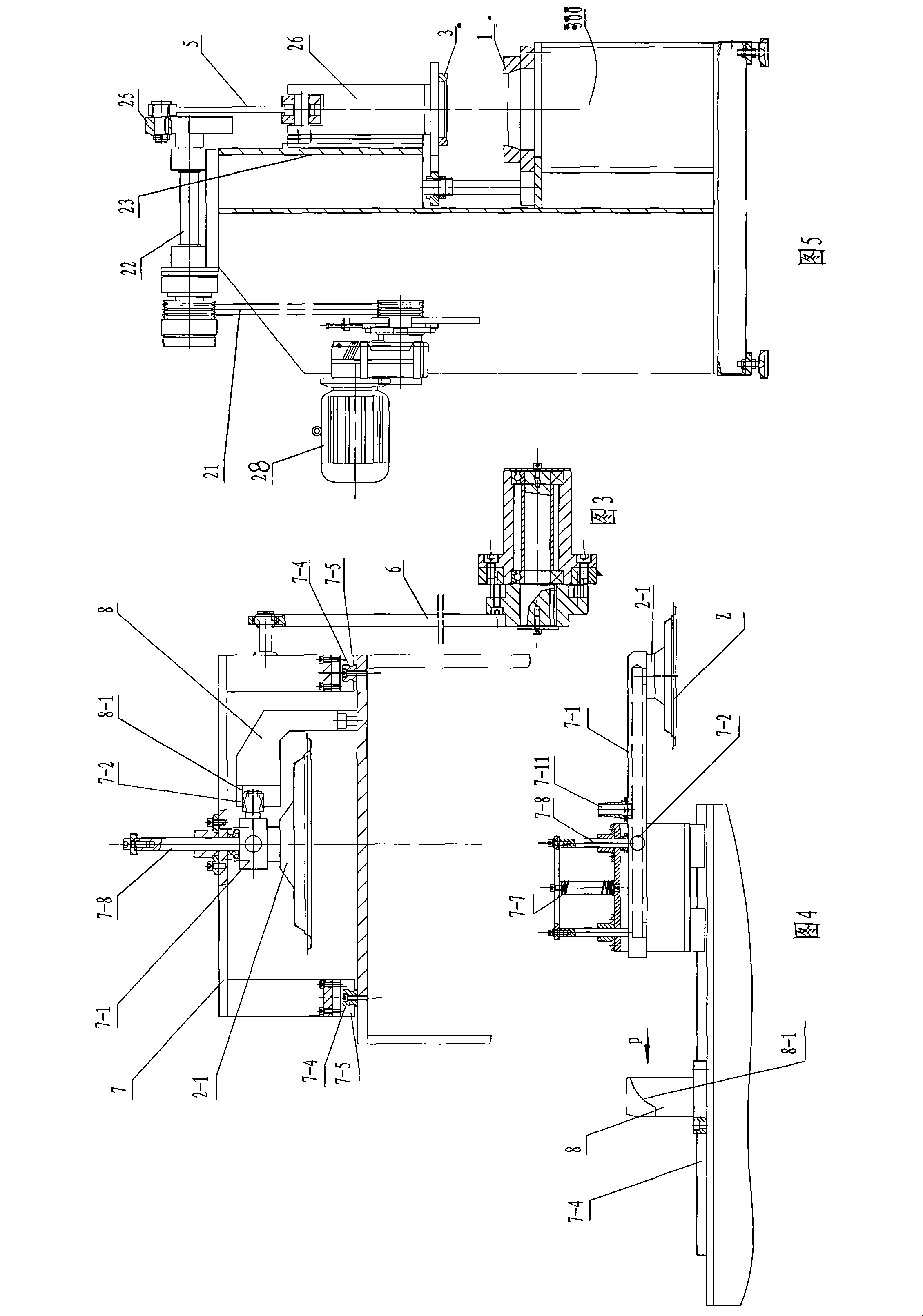

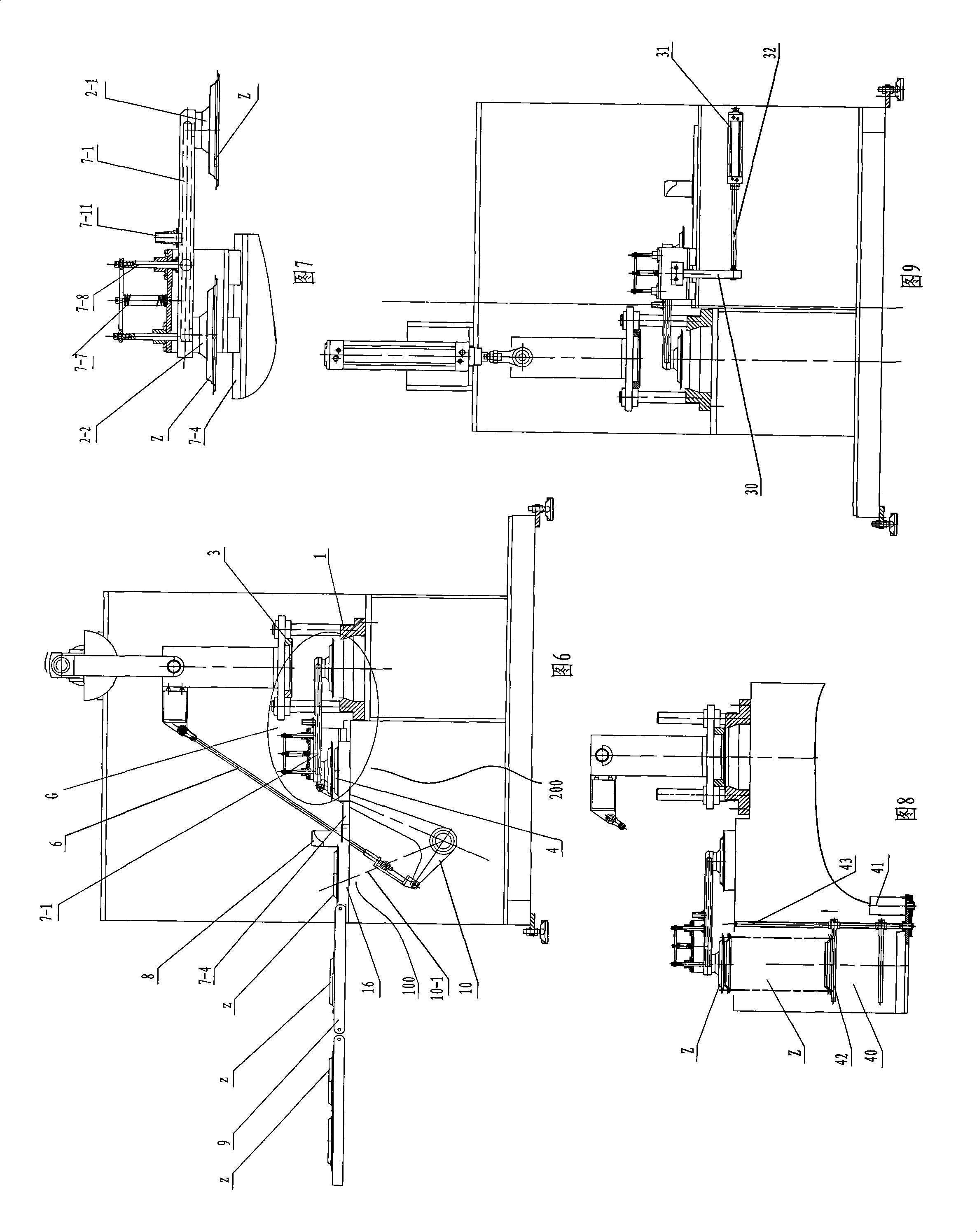

[0039] As shown in Figure 5, the edge trimming station 300 in the full-automatic plant fiber molded product edge trimming machine, the included edge trimming mold and the power mechanism driving the edge trimming mold are all existing mechanisms; wherein: the power transition of the upper mold The plate 26 can slide vertically up and down along the slide rail on the vertical plate 23 of the frame; since the connecting rod 5 hinged on the crank 25 at one end of the shaft 22 is hinged with the power transition plate 26 of the upper die, the motor 28 drives the shaft through the transmission belt 21 After 22 rotations, the edge trimming upper die 3 just reciprocates up and down, and cooperates with the edge trimming lower die 1 to trim the edges of the molded products put therein.

[0040] In the present invention, a preparation station 100 is added next to the edge trimming station, and a transfer device is arranged to transport the products to be cut sequentially between the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com