Pulp molded product edge trimming, bronzing and paper edge polishing linkage production line and method

A pulp molding, production line technology, used in grinding/polishing equipment, processes for producing decorative surface effects, gold powder printing, etc., can solve the inefficiency of bronzing and polishing, and cannot produce high quality on the same machine. products, etc., to achieve the effect of improving processing quality, production efficiency, and guaranteeing hygienic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

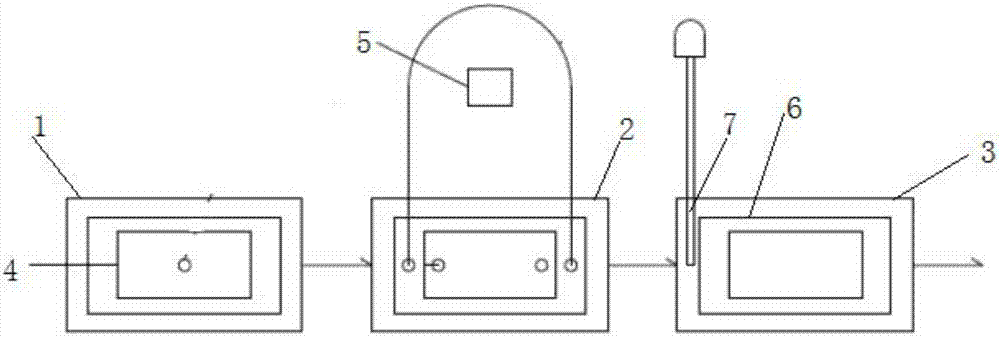

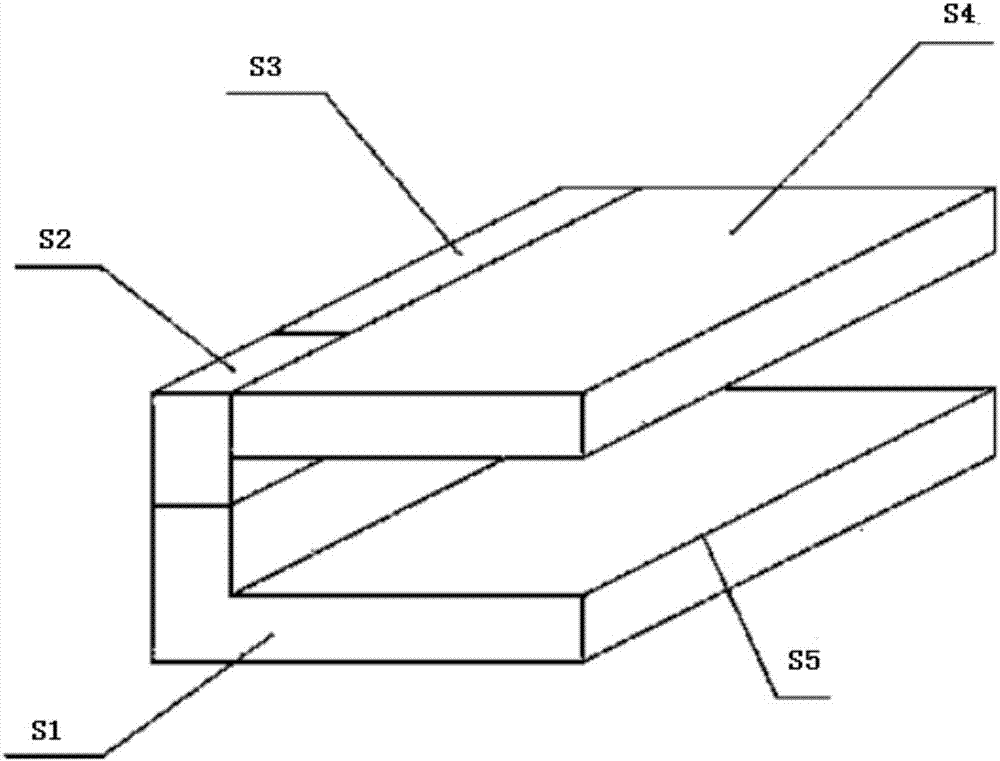

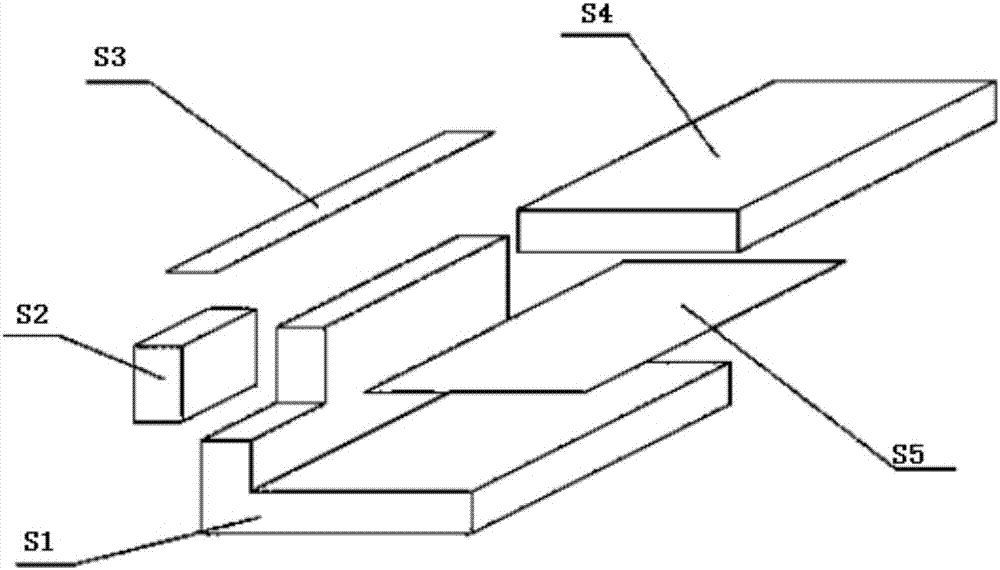

[0024] According to attached Figure 1-Figure 5 It can be seen that the pulp molding product edge trimming, bronzing and paper edge polishing linkage production line of the present invention includes a sequentially connected feeding table 1, a synchronization device 2 for edge trimming and bronzing, and an edge polishing device 3;

[0025] The feeding table 1 includes a preparation station, and the preparation station is provided with a positioning plate 4 that facilitates the positioning of the products to be cut, and is equipped with a conveyor belt for transporting the products to be cut, and the conveyor belt is used to send the products to be cut into the positioning plate 4 ;

[0026] The synchronous device 2 of trimming and bronzing comprises a trimming station, a power mechanism for trimming molds and driving trimming molds is arranged in the trimming stations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com