Polyurethane and foamed cement microscopically-composite heat insulating material and preparation method therefor

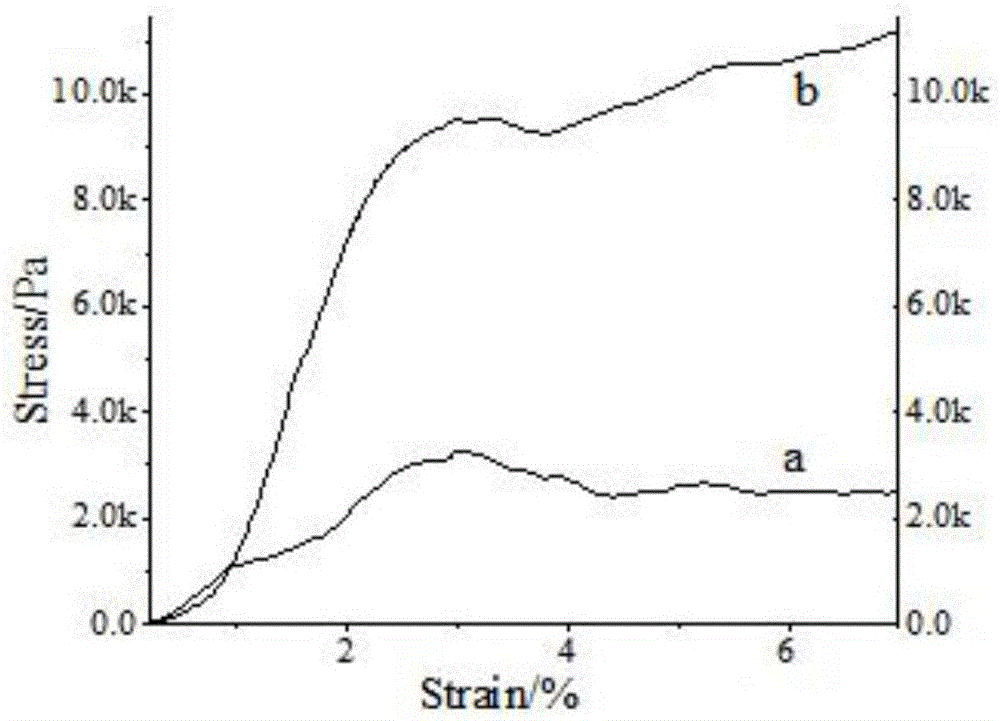

A foamed cement and thermal insulation material technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of low strength, high brittleness, high bulk density, and achieve the effects of high weather resistance, improved comprehensive performance, and stable composite interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

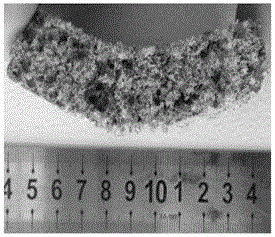

[0028] (1) Stir 100 parts of P.O.42.5 cement, 0.5 parts of PP chopped fiber, 2 parts of calcium formate, 1.5 parts of sodium dodecylbenzenesulfonate foam stabilizer with 50 parts of hot water at 45°C for 3 minutes according to the conventional method , quickly add 5 parts of hydrogen peroxide, and at the same time, stir at high speed for 10s, then pour into the mold, let it stand for 24hrs to demould, 48hrs to cut, then cured at room temperature to age and dried to constant weight.

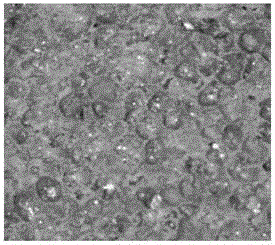

[0029] (2), first 13 parts of crude diphenylmethane diisocyanate, 10 parts of polyether polyol, 0.2 part of polysiloxane polyether, 0.01 part of diisobutyltin dilaurate catalyst are mixed into a homogeneous slurry, and then the step (1) Submerge the prepared dry foamed cement in the slurry, take it out after the slurry is completely soaked into the foamed cement, and let it solidify for 2 hours;

[0030] (3) Immerse the foamed cement obtained in step (2) into water again, and with the diffusion an...

Embodiment 2

[0033] (1), 85 parts of P.O.42.5 cement, 15 parts of Class I fly ash, 1.0 parts of PP chopped fiber, 1.5 parts of calcium formate, and 2.0 parts of sodium lauryl sulfate foam stabilizer were mixed with 55 parts of 47 ℃ according to the conventional method. After stirring in hot water for 2 minutes, quickly add 5.3 parts of hydrogen peroxide, and at the same time stir at high speed for 10 seconds, then pour it into the mold, let it stand for 24 hours to remove the mold, cut it for 48 hours, and then cure it at room temperature until it reaches its age and dry it to constant weight.

[0034] (2), first 20 parts of polymethylene polyphenyl diisocyanate, 15 parts of polyether polyol, 0.4 part of polysiloxane polyether, 0.1 part of triethylenediamine catalyst are mixed into a uniform slurry, and then the step (1) Submerge the prepared dry foamed cement in the slurry, take it out after the slurry is completely soaked into the foamed cement, and let it solidify for 3 hours;

[0035] (3...

Embodiment 3

[0038] (1), 90 parts of P.C.32.5 cement, 10 parts of grade II fly ash, 0.7 part of PP chopped fiber, 1.0 part of calcium formate, 2.0 parts of α-alkenyl sulfonate sodium foam stabilizer with 47 parts of 40 according to the conventional method After stirring in hot water at ℃ for 2 minutes, quickly add 4.5 parts of hydrogen peroxide, and at the same time stir at high speed for 10 seconds, then pour into the mold, let it stand for 24 hours to demould, cut for 48 hours, and then cure at room temperature to age and dry to constant weight.

[0039] (2), first 10 parts of toluene diisocyanate, 9 parts of polyether polyols, 0.15 parts of polysiloxane polyethers, 0.2 parts of bis(dimethylaminoethyl) ether catalysts are mixed into a homogeneous slurry, and then the step ( 1) Immerse the prepared dry foamed cement in the slurry, take it out after the slurry is completely soaked into the foamed cement, and let it stand for 4 hours to solidify;

[0040] (3) Immerse the foamed cement obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com