The bag feeding mechanism of the filling machine

A filling machine and filling technology, applied in packaging and other directions, can solve problems such as manufacturing troubles, transformation, and insufficient attractiveness of producers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

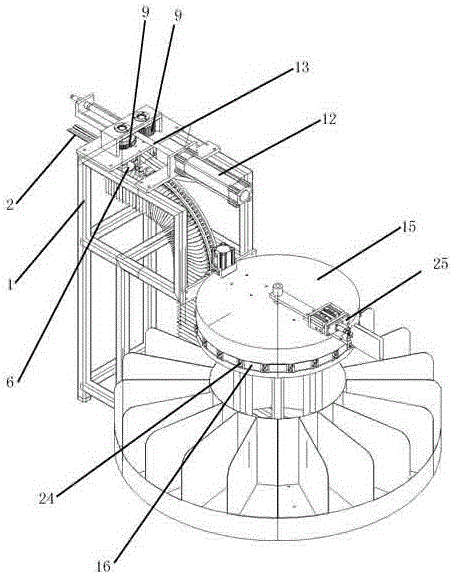

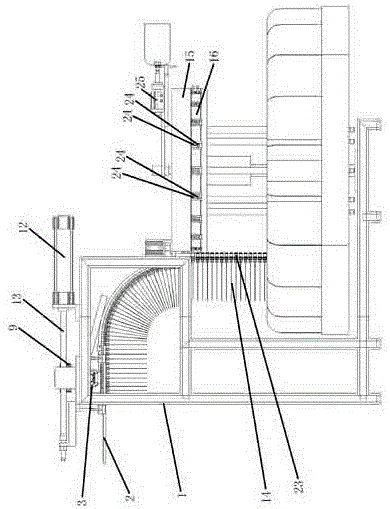

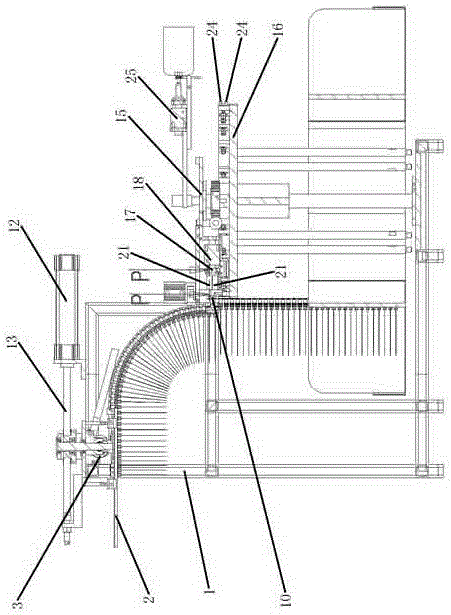

[0035] Such as Figure 1-7 As shown, the bag-feeding mechanism of the filling machine in this embodiment includes a frame 1 , a splice mechanism and a tube-extracting mechanism, and the above-mentioned tube-extracting mechanism is installed on the mechanism frame 1 .

[0036]The above-mentioned extubation mechanism includes a positioning chute 2 for filling and drinking pipes, a stripping mechanism for serially connected sheets, a pinching pipe mechanism, and a driving mechanism.

[0037] The above-mentioned pinch pipe mechanism is located above the positioning chute 2 of the filling drinking pipe, and the above-mentioned series strip stripping mechanism is located above the pinch pipe mechanism.

[0038] The above-mentioned serial sheet stripping mechanism includes a positioning transmission roller 3, the above-mentioned positioning transmission roller 3 is erected and rotatably installed on the frame 1 through a rotation shaft, and the rotation axis of the positioning transm...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is:

[0056] The above-mentioned driving device is a second motor, and a transmission gear 9 of the above-mentioned transmission mechanism is installed on the output shaft of the second motor.

[0057] The driving mechanism of the suspension turntable is composed of a cylinder, rack, gear, etc., but it must be noted that the gear needs to be installed on the rotation shaft of the suspension turntable through a one-way bearing, so that the gear can only drive the rotation shaft of the suspension turntable in one direction.

Embodiment 3

[0059] The difference between this embodiment and embodiment 1 is:

[0060] The above-mentioned driving mechanism adopts two driving devices to respectively drive the serial sheet peeling mechanism and the pinch pipe mechanism to rotate. The advantage of this design is that the rotation of the serial sheet peeling mechanism and the pinch tube mechanism can be adjusted separately according to the needs, so that the cooperation between the two is more precise, but the disadvantage is that the cost is relatively high.

[0061] The above-mentioned driving device is a motor. Above-mentioned motor can adopt servo motor or stepper motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com