A magnetic capping device

A screw cap, magnetic technology, applied in the direction of screw caps, etc., can solve problems such as over-tightening of caps, pulse vibration of system parts, shortening the life of parts, etc., to achieve the effect of fixing, rotating smoothly, and reducing the difficulty of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples.

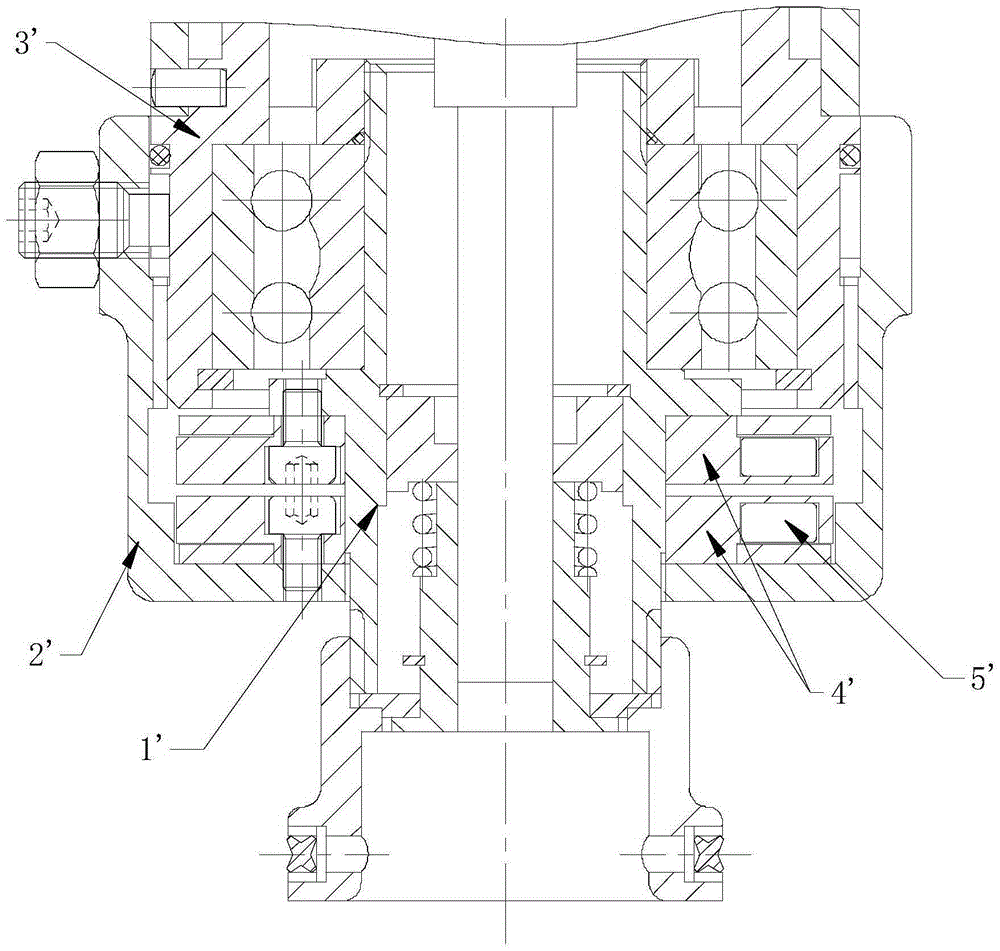

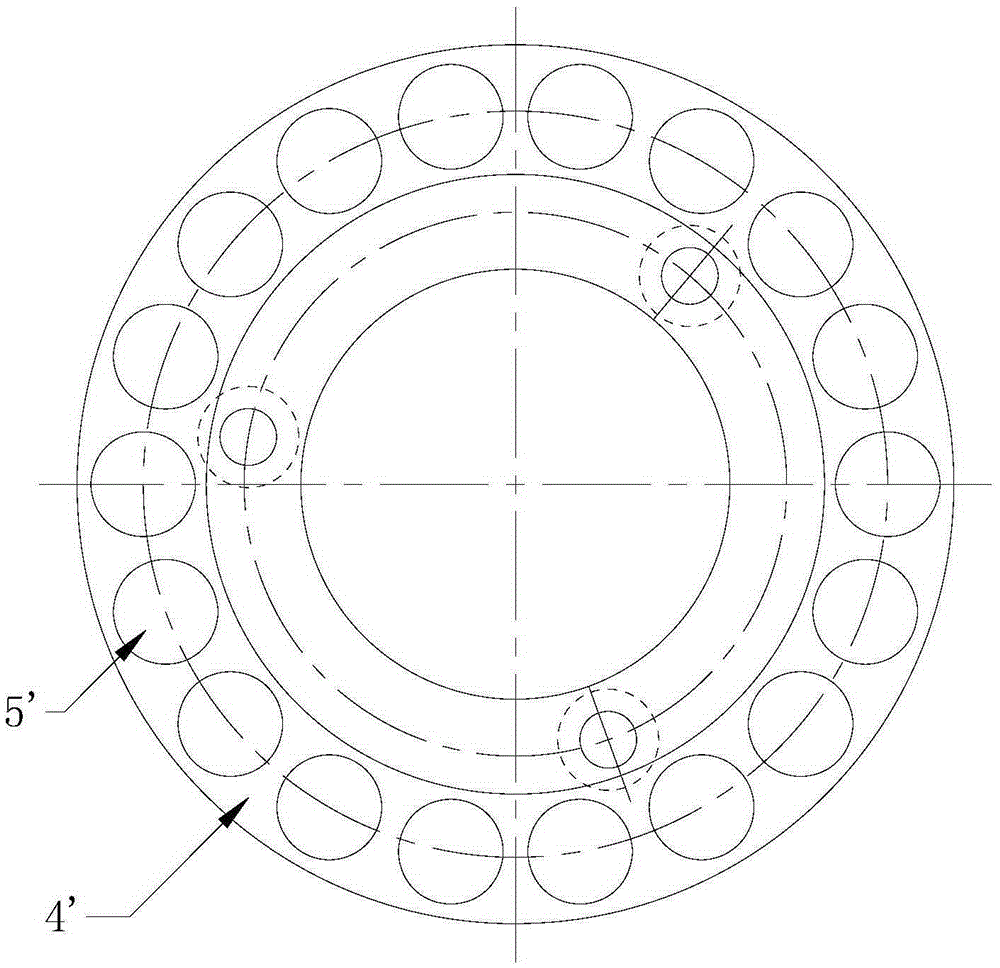

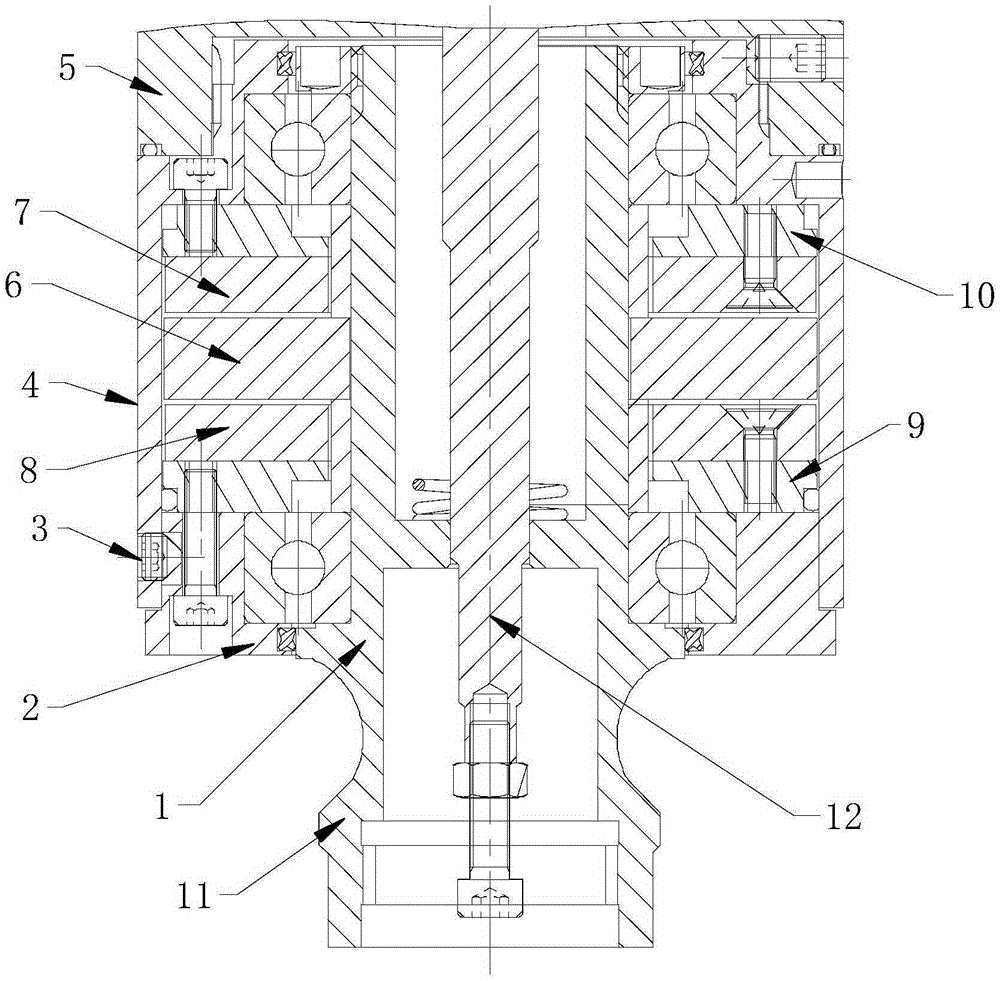

[0021] Such as image 3 , 4 As shown, a magnetic capping device includes a hollow shaft 1 and an adjusting ring 2. A top cover device 12 is installed elastically in the axial direction of the hollow shaft 1. The top cover device 12 includes a Top cap shaft; a return spring is arranged between the top cap shaft and the hollow shaft 1; when the bottle cap enters the screw capping mold 11 and is ready to be screwed, the top cap shaft will push against the upper end of the bottle cap, thereby making the bottle cap swing Positively, the lower end of the hollow shaft 1 is equipped with a capping mold 11, which can be detachably installed on the lower end of the hollow shaft 1, or can be integrated with the hollow shaft 1; the capping device also includes a power input sleeve 5. The fixed sleeve 4, the upper magnetic ring 7, the lower magnetic ring 8 and a magnetic ring 6; the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com