A high-efficiency quenching plate quenching process

A process and steel plate technology, applied in the field of quenching plate production in heat treatment furnaces, can solve the problems of long valve adjustment time, water circulation system does not meet quenching conditions, etc., and achieve the effect of shortening quenching waiting time, maintaining fluctuations, and reducing water replenishment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

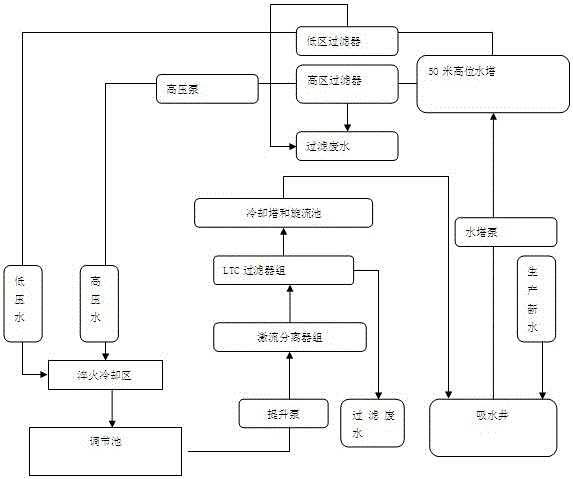

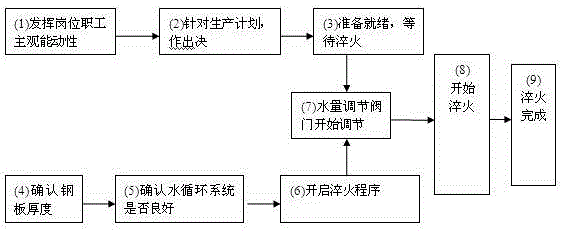

Method used

Image

Examples

Embodiment 1

[0037] In the high-efficiency quenching plate quenching process of the present invention, all employees participate in the production rhythm control, and water pump workers are included in the production rhythm control. When producing steel plates with a thickness ≥ 40mm, the water replenishment valve is opened 8-10 minutes in advance, so that the production of new water is replenished in advance, 5 in advance Turn on two water tower pumps and one high-pressure pump in minutes.

[0038] The opening and closing of the lifting pump is controlled manually according to the liquid level display of the regulating pool and the suction well. When the water level of the regulating pool is lower than 3.5 meters, the lifting pump must be closed; When the water level is below 5.5 meters, one lift pump is turned on; when the water level of the regulating pool is above 5.5 meters and the water level of the suction well is below 5.5 meters, two lift pumps are turned on.

[0039] The adjustme...

Embodiment 2

[0051] When producing steel plates with a thickness less than 40mm, the water supply valve should be opened 3-5 minutes in advance, and one water tower pump and two high-pressure pumps should be opened 5 minutes in advance.

[0052] Other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com