Method of depositing film

A film-forming method and technology of a film-forming device, which are applied in the directions of gaseous chemical plating, coating, electrical components, etc., can solve problems such as inability to properly adsorb, film wafers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0032] Film forming device

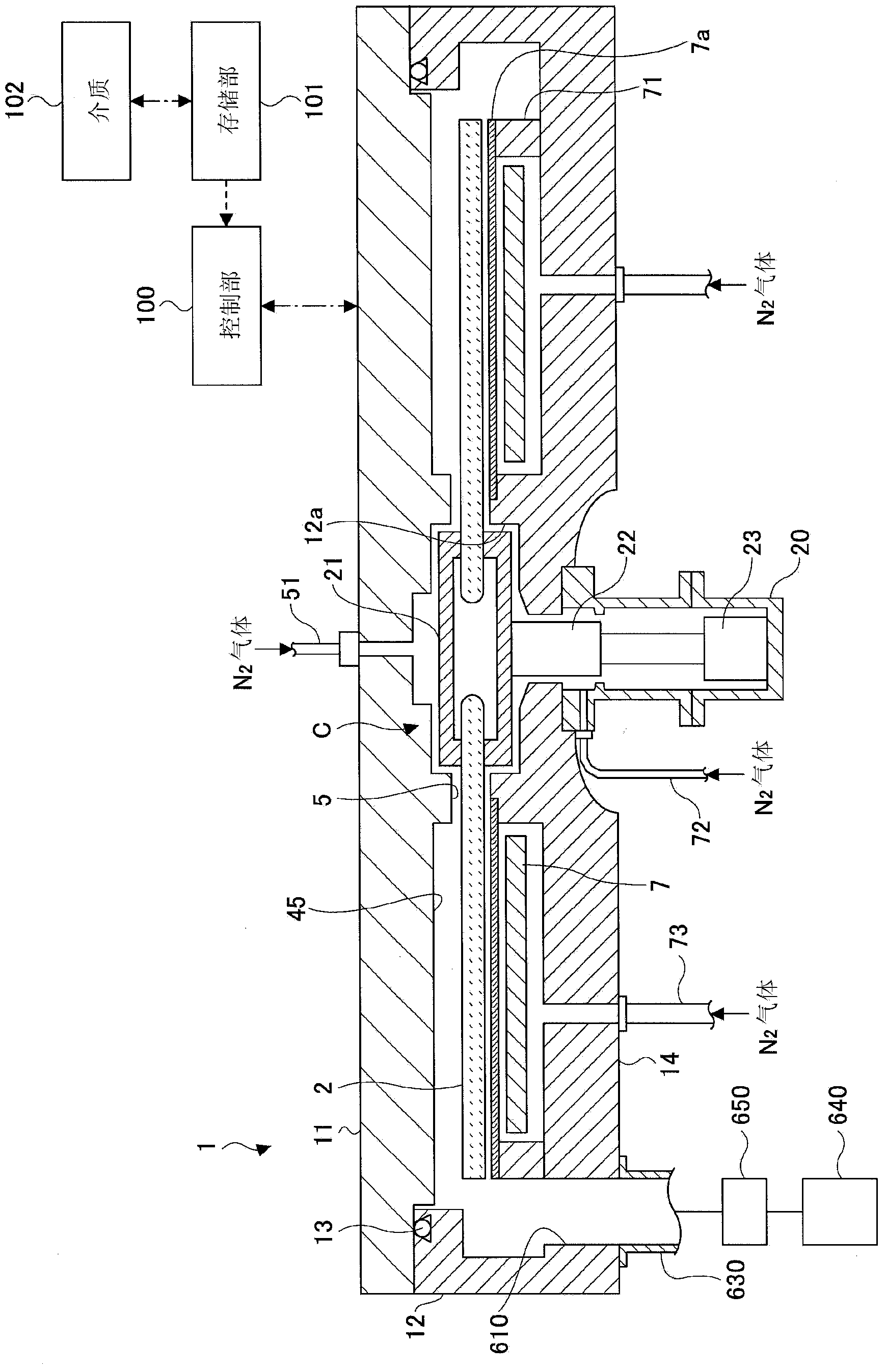

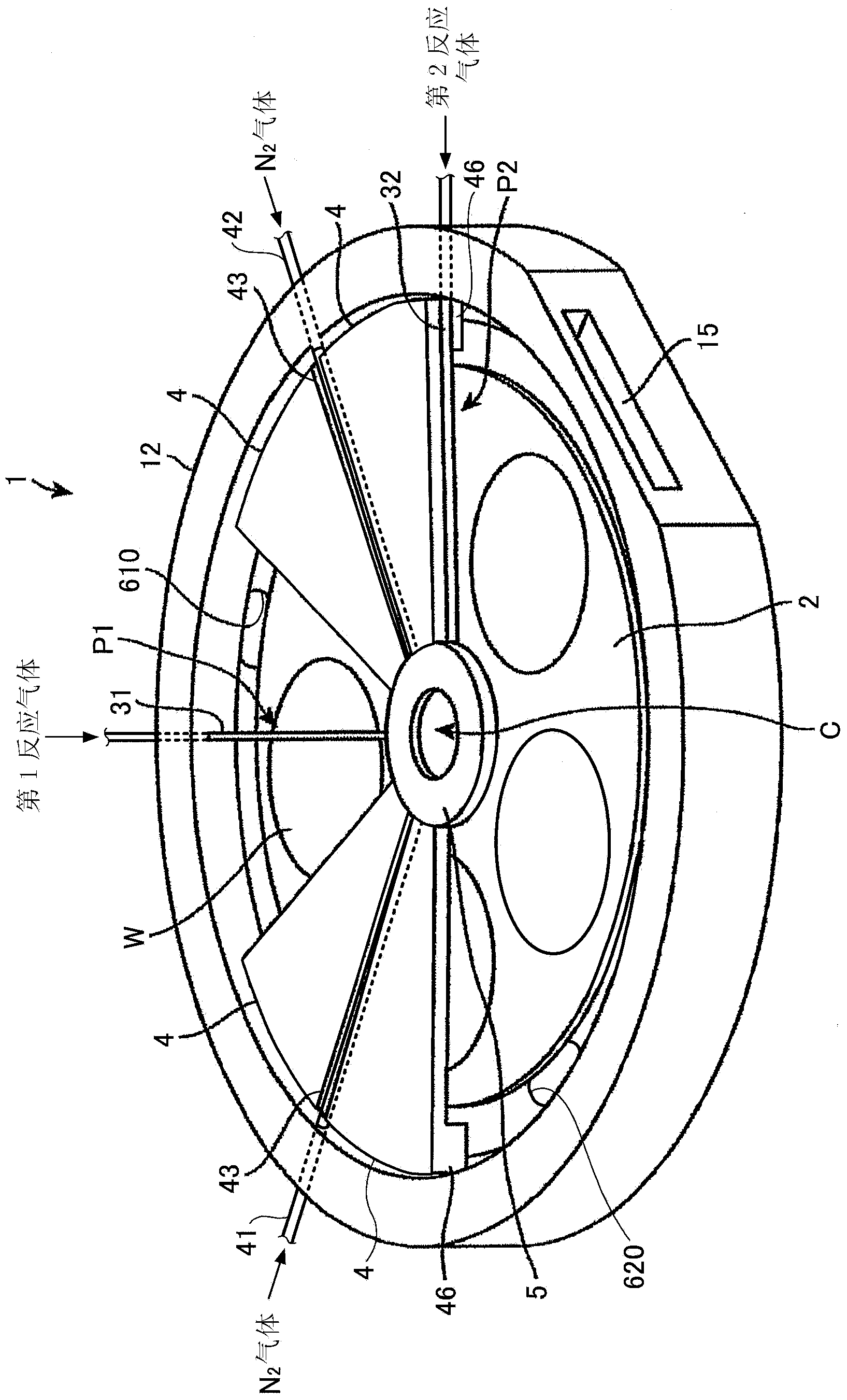

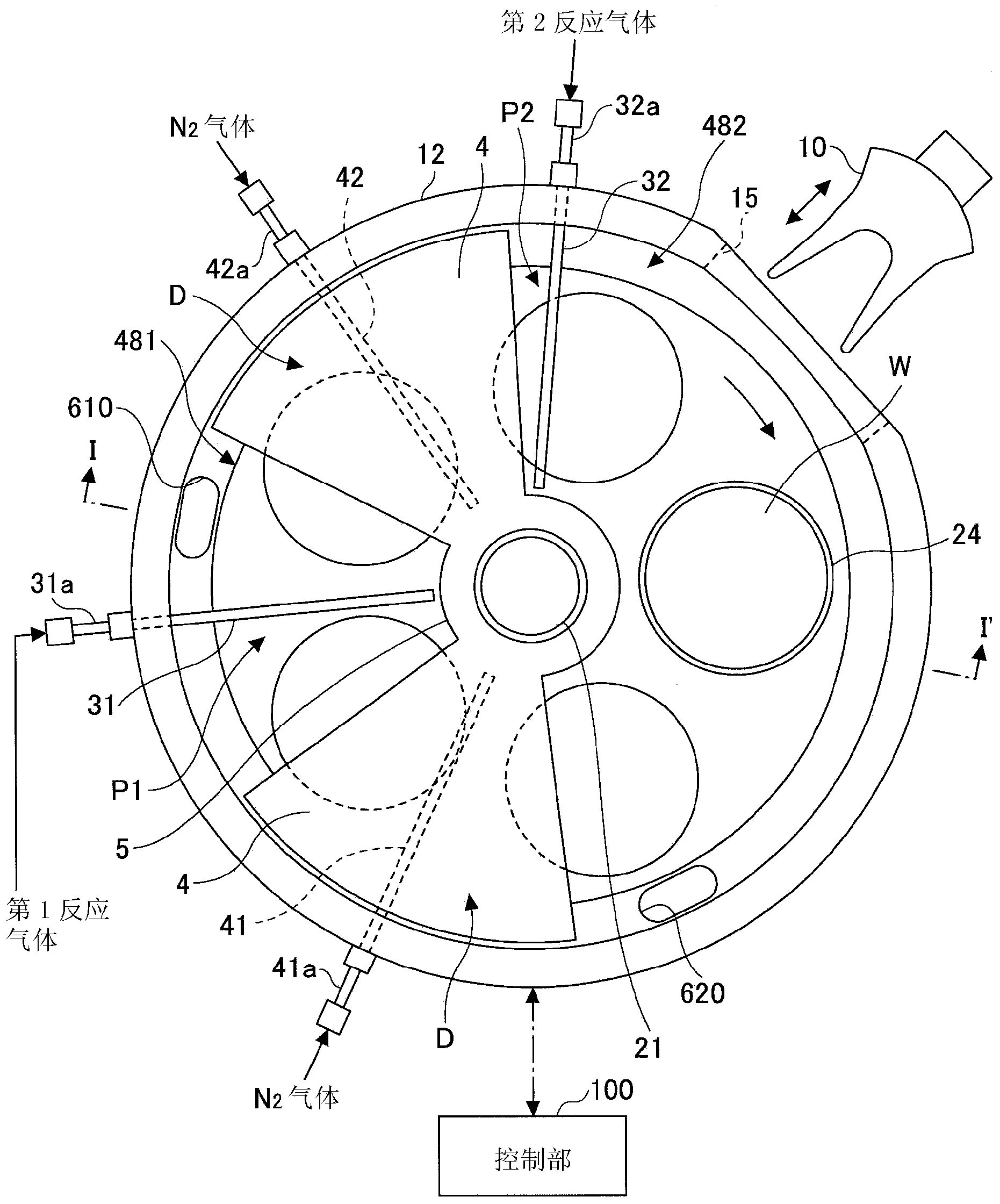

[0033] First, use Figure 1 ~ Figure 3 A film forming apparatus suitable for carrying out the film forming method according to Embodiment 1 of the present invention will be described.

[0034] figure 1 It is a cross-sectional view showing a film forming apparatus suitable for carrying out the film forming method according to the embodiment of the present invention. figure 2 yes means figure 1 A perspective view of the structure inside the vacuum vessel of the film formation apparatus. image 3 yes means figure 1 A schematic plan view of the structure inside the vacuum chamber of the film formation apparatus.

[0035] refer to Figure 1 to Figure 3 , The film forming apparatus of Embodiment 1 includes: a flat chamber 1 having a substantially circular planar shape; The chamber 1 has: a container main body 12 having a bottomed cylindrical shape; a top plate 11 sandwiching a sealing member 13 such as an O-ring ( figure 1 ) is airtightly and ...

Embodiment approach 2

[0100] Figure 8 It is a sequence diagram showing an example of the film forming method according to Embodiment 2 of the present invention. In the film formation method of Embodiment 2, it is explained that the hafnium oxide (HfO) film and silicon oxide (collectively referred to as "SiO") may contain SiO 2 ) film formed as an example of an HfSiO film in a laminated configuration. The HfSiO film is also used as a so-called High-k film having a high dielectric constant.

[0101] In addition, in Embodiment 2, an example in which the same film-forming apparatus as that described in Embodiment 1 is used as the film-forming apparatus will be described. In addition, descriptions of the same contents as in Embodiment 1 are omitted or simplified as appropriate.

[0102] exist Figure 8 In step 1, a standby process is performed. In addition, since the content of introducing the wafer W into the chamber 1 until entering the standby process is the same as that described in Embodiment...

Embodiment approach 3

[0124] Figure 10 It is a figure which shows an example of the sequence of the film-forming method of Embodiment 3 of this invention. In Embodiments 1 and 2, an example of forming an oxide film was given and described, but in Embodiment 3, an example of forming a nitride film will be described. Specifically, in the film-forming method of Embodiment 3, film-forming of a TiAlN film having a laminated structure composed of a TiN film and an AlN film will be described as an example. In addition, a TiAlN film is also used as a so-called High-k film having a high dielectric constant.

[0125] In addition, in Embodiment 3, an example in which the same film formation apparatus as that described in Embodiments 1 and 2 is used as the film formation apparatus will be described. In addition, descriptions of the same contents as those in Embodiments 1 and 2 are appropriately omitted or simplified.

[0126] exist Figure 10 In the same manner as Embodiments 1 and 2, the turntable 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com