Laminated outdoor roof tiles

A layered, outdoor technology, applied in the direction of roofing, layered products, roof coverings, etc., can solve the problems of uncoordinated tiles, cumbersome laying process, unfavorable maintenance, etc., to meet the needs of waterproofing, simple structure, and improve heat preservation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

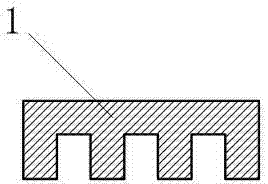

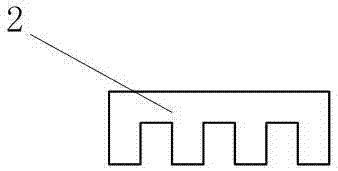

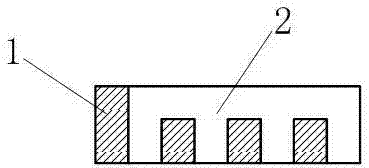

[0016] Such as Figure 1~3 The stacked outdoor roof tiles shown include base-level roof tiles, and its special feature is that the utility model adopts stacked staggered-layer decorative tiles on the base-level roof tiles. Specifically, the staggered decorative tiles are placed at an interval from the underlying roof tiles. In this way, due to the staggered interval, the relative thickness between the roof tiles can be increased, and the performance of waterproof and heat insulation can be improved. Moreover, the overall number of layers can be adjusted according to the location of the house.

[0017] At the same time, in order to facilitate the laying and guide the flow of rainwater, one end of the grass-roots roof tiles is used as the main connection end, and the other end of the grass-roots roof tiles is the main flow end. Correspondingly, one end of the staggered decorative tile is the auxiliary connecting end, and the other end of the staggered decorative tile is the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com