A hidden rotary lock cylinder and unlocking key

A rotary lock cylinder, hidden technology, applied in the field of locks and keys suitable for the locks, to achieve the effect of strong unlocking feeling and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

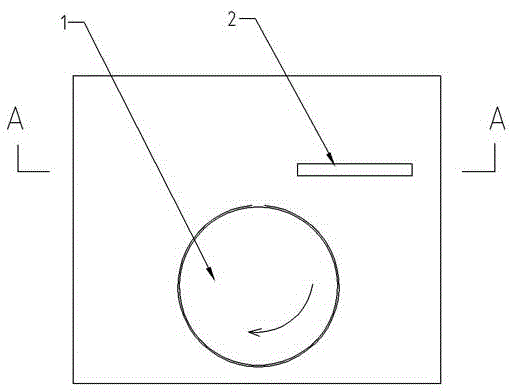

[0020] Attached figure 1 Shows a hidden rotary lock core, including a lock core and a rotary lock drive bolt 1; the lock core is a square block with a round through hole in the middle.

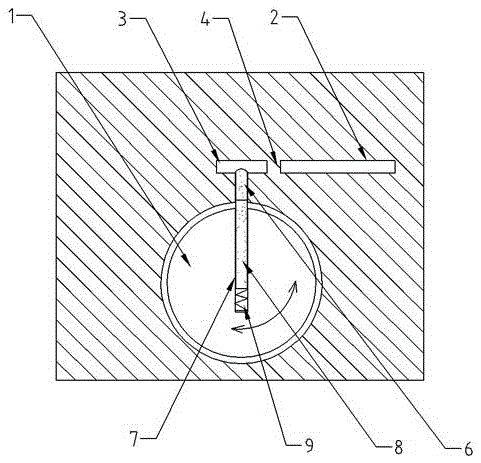

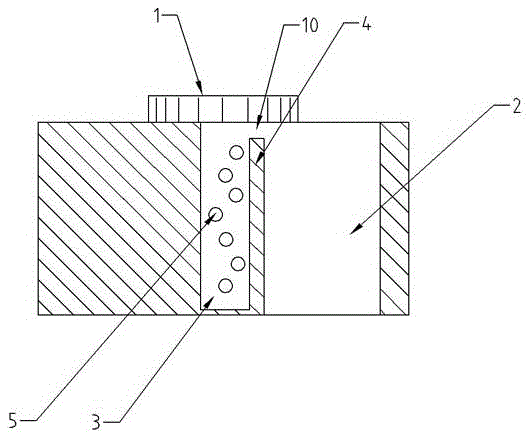

[0021] figure 2 with image 3 It means that two strip holes with different widths are arranged in parallel inside the lock cylinder; among them, the wide strip hole 2 communicates with the front face of the square block to form an insertion port; the narrow strip hole 3 does not communicate with the front face of the square block; A partition wall 4 is formed in the lock core between the wide strip hole 2 and the narrow strip hole 3; the narrow strip hole 3 has a section of marble holes 5, and each marble hole 5 has a side pillar pin 6; The rotary lock drive bolt 1 is movably matched with the round through hole of the lock cylinder, so that the rotary lock drive bolt 1 can rotate relative to the lock cylinder to realize direct or indirect unlocking; the rotary lock drive bolt 1 is provided with a...

Embodiment 2

[0025] A hidden rotary lock core includes a lock core and a rotary lock drive bolt 1; the lock core is a cylindrical block with a round through hole in the middle. Two strip-shaped channels with different widths are arranged in parallel inside the lock cylinder; among them, the wide strip-shaped channel 2 communicates with the front of the cylindrical block to form an insertion port; the narrow strip-shaped channel 3 does not communicate with the front face of the cylindrical block; A partition wall 4 is formed in the lock core between the wide strip hole 2 and the narrow strip hole 3; the narrow strip hole 3 has a section of marble holes 5, and each marble hole 5 has a side pillar pin 6; The rotation lock drive bolt 1 is movably matched with the round through hole of the lock cylinder, so that the rotation lock drive bolt 1 can rotate relative to the lock cylinder to achieve direct or indirect unlocking; the cylinder surface of the rotation lock drive bolt 1 is provided with T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com