Method for welding well ground pipeline for gas extraction in mining area

A technology of gas drainage and welding method, which is applied in the fields of gas emission, mining equipment, earth-moving drilling and mining, etc., can solve the problems of reducing production efficiency, combustion, and inability to weld the surface wellhead well pipe, so as to avoid temperature rise and ensure safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

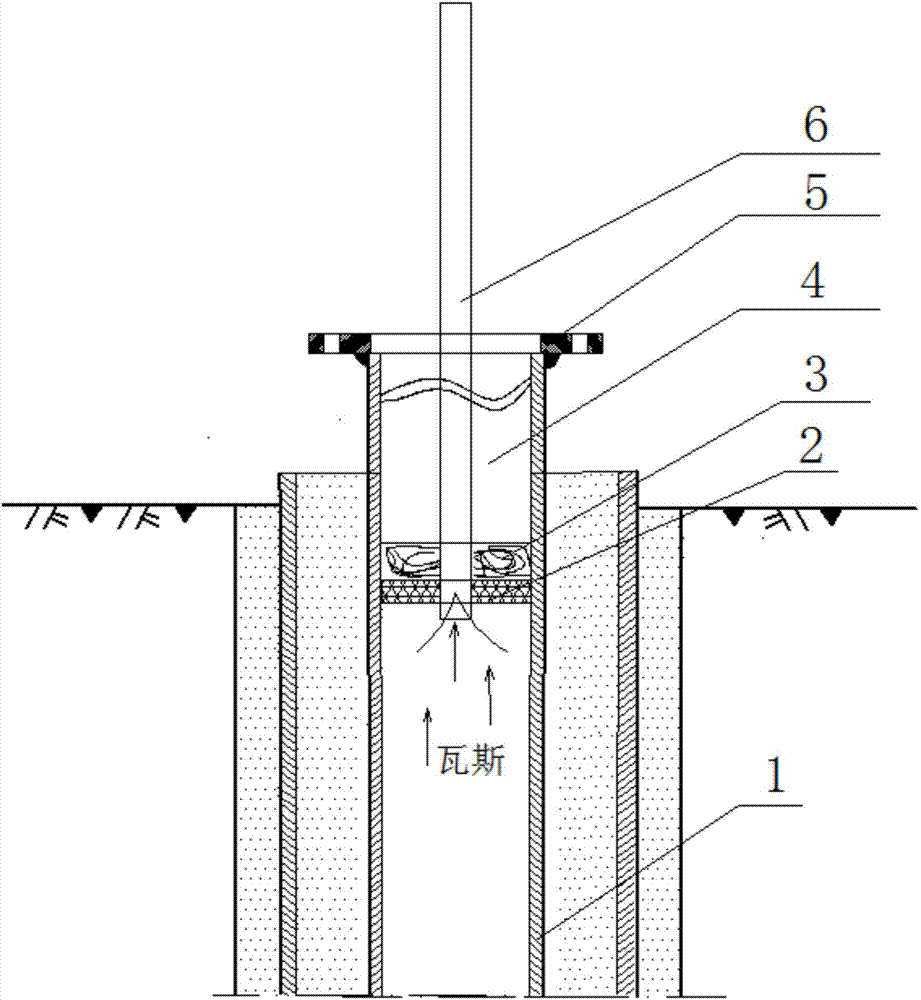

[0019] Such as figure 1 Shown, concrete steps of the present invention are:

[0020] A. Install a water-stop isolation strip at the end of the air duct 6;

[0021] B. Insert the protruding end of the air guide pipe 6 into the mining well pipe 1, so that the water-stop isolation zone and the mining well pipe 1 are closely attached; the ground height of the air guide pipe 6 is not less than 5m, so that Exported gas diffuses to the ground in concentrations below those capable of burning or detonating;

[0022] C. Inject mud or water from the port of the mining well pipe 1 to ensure that the mud or water depth above the water-stop isolation zone is not less than 2m to form a liquid blocking layer 4;

[0023] D. Perform flange 5 welding on the port of mining well pipe 1;

[0024] E. If the mud or water in the mining well pipe 1 drops during the welding process, continue to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com