Impeller without hump

A hump and impeller technology, applied in the field of impellers with no hump head, can solve the problems of energy loss, unstable operation of the pump set, hump of the flow head curve, etc., and achieve the effect of reducing inlet backflow, avoiding energy loss, and expanding the operating area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the appendix of the embodiment picture Specific embodiments of the present invention will be described in detail.

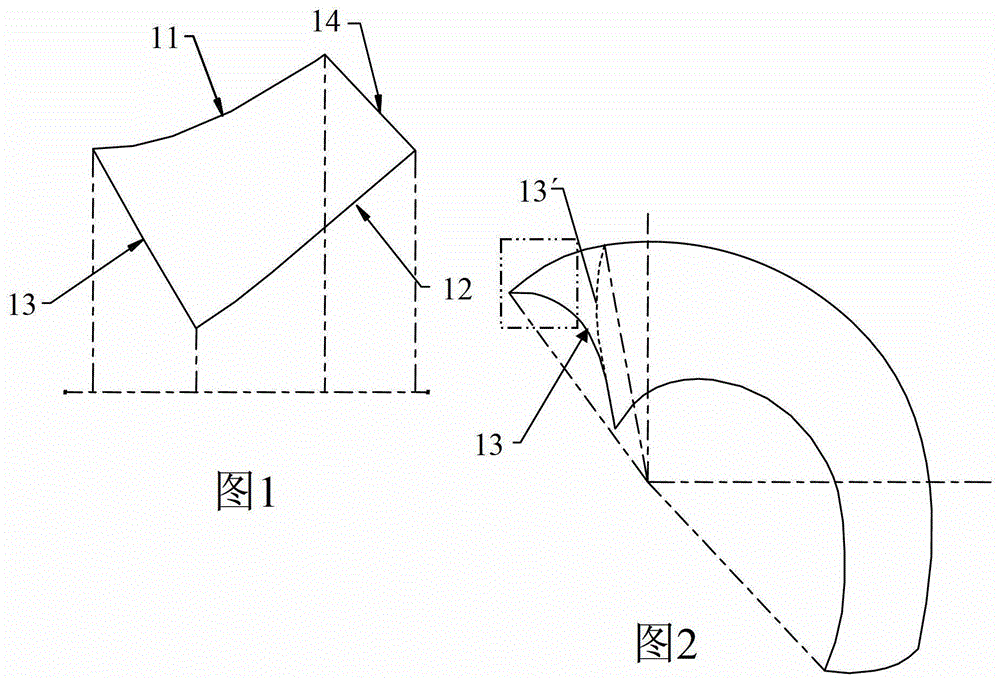

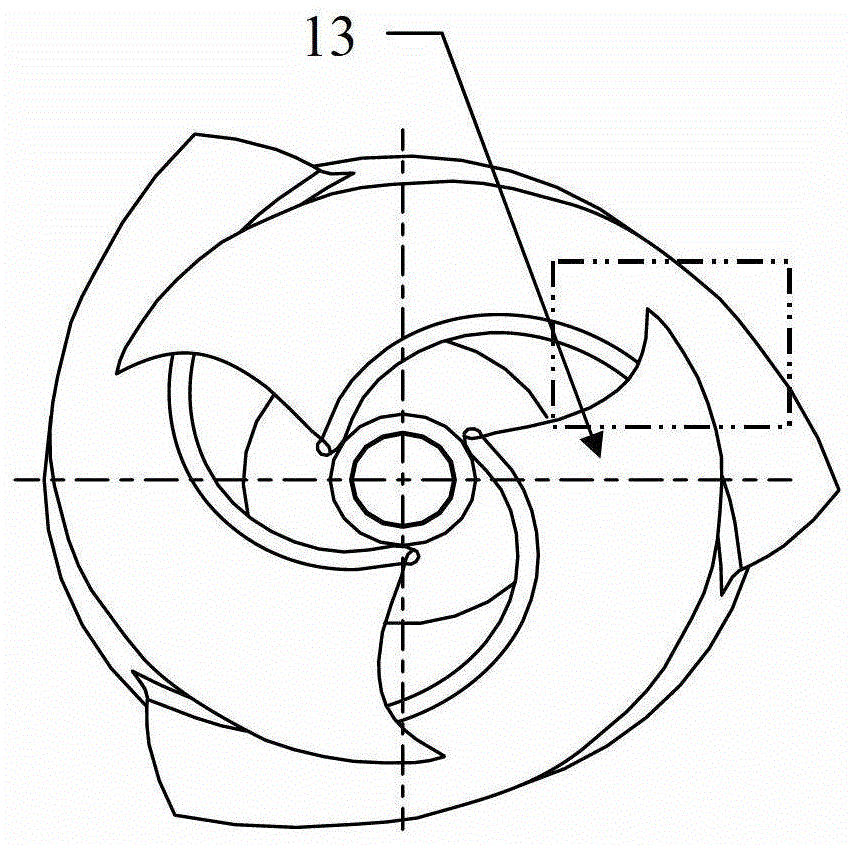

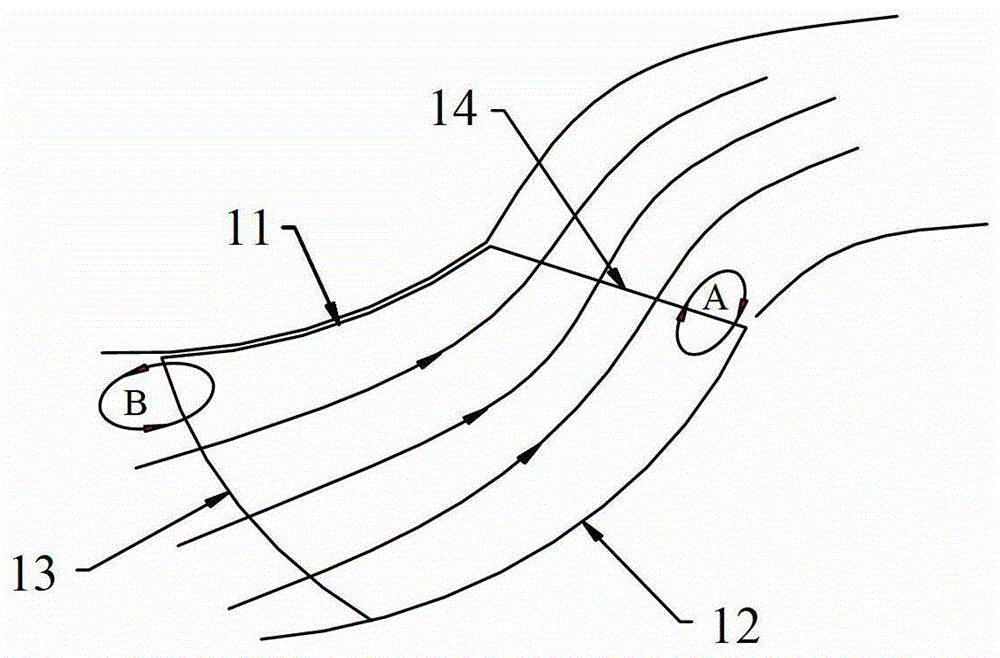

[0019] The impeller is located at the bottom of the volute of the pump, see Figure 1, the impeller includes a blade front cover 11, a blade rear cover 12, a hub and blades inside it, and multiple groups of blades are evenly distributed in front of the blades There is a fluid channel between the cover plate and the blade rear cover, and between the blades. The blade is firmly connected with the blade front cover and the blade rear cover by integral casting or welding. The blade rotates together through the shaft connected to the hub. The fluid flows along the working surface from the inlet side 13 of the blade to the outlet side 14 of the blade under the rotation of the blade, thereby realizing the function of pumping fluid.

[0020] As shown in Figures 1-3, the impeller with a head without a hump in the present invention adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com