Speed reducer special for cooling tower and air cooler

An air cooler and cooling tower technology, applied in mechanical equipment, transmission parts, gear transmission and other directions, can solve the problems of unstable transmission ratio and high noise of the reducer, and achieve a simple structure, low noise and high transmission efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

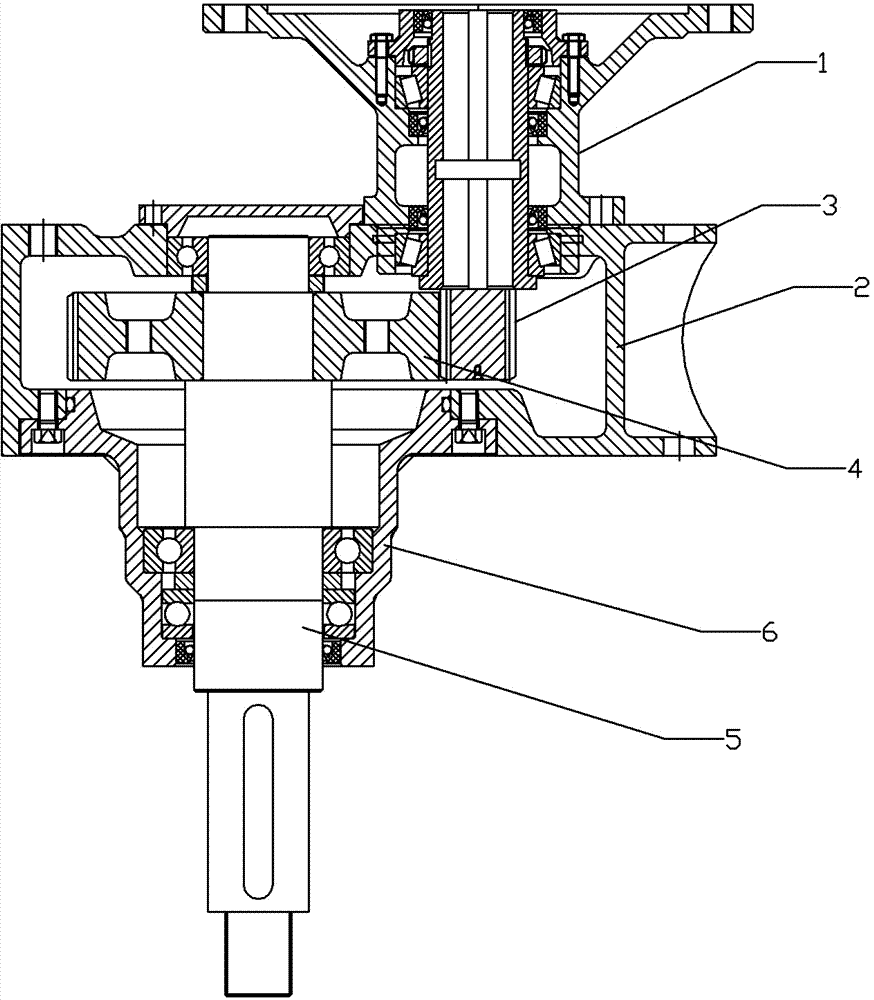

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0013] Such as figure 1 The special reducer for cooling towers and air coolers shown includes connecting plate 1, gear box 2, bearing seat 6, driving gear 3, driven gear 4 and main shaft 5, and connecting plate 1, gear box 2 and bearing seat 6 pass through The bolts are connected as a whole, which is very convenient for assembly, disassembly and maintenance. Based on this split structure, the driving gear of the general reducer is easily damaged and needs to be repaired or replaced. Therefore, when it is necessary to repair or replace the driving gear, it is not necessary to replace the entire When the reducer is removed from the equipment, it is only necessary to remove the connecting plate and the driving gear as a whole, which greatly facilitates the maintenance of the reducer.

[0014] The upper bearing of the main shaft 5 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com