Plate-type gas combustion condensing water boiler

A gas-fired, hot-water boiler technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of inability to condense water vapor, low boiler efficiency, and high exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

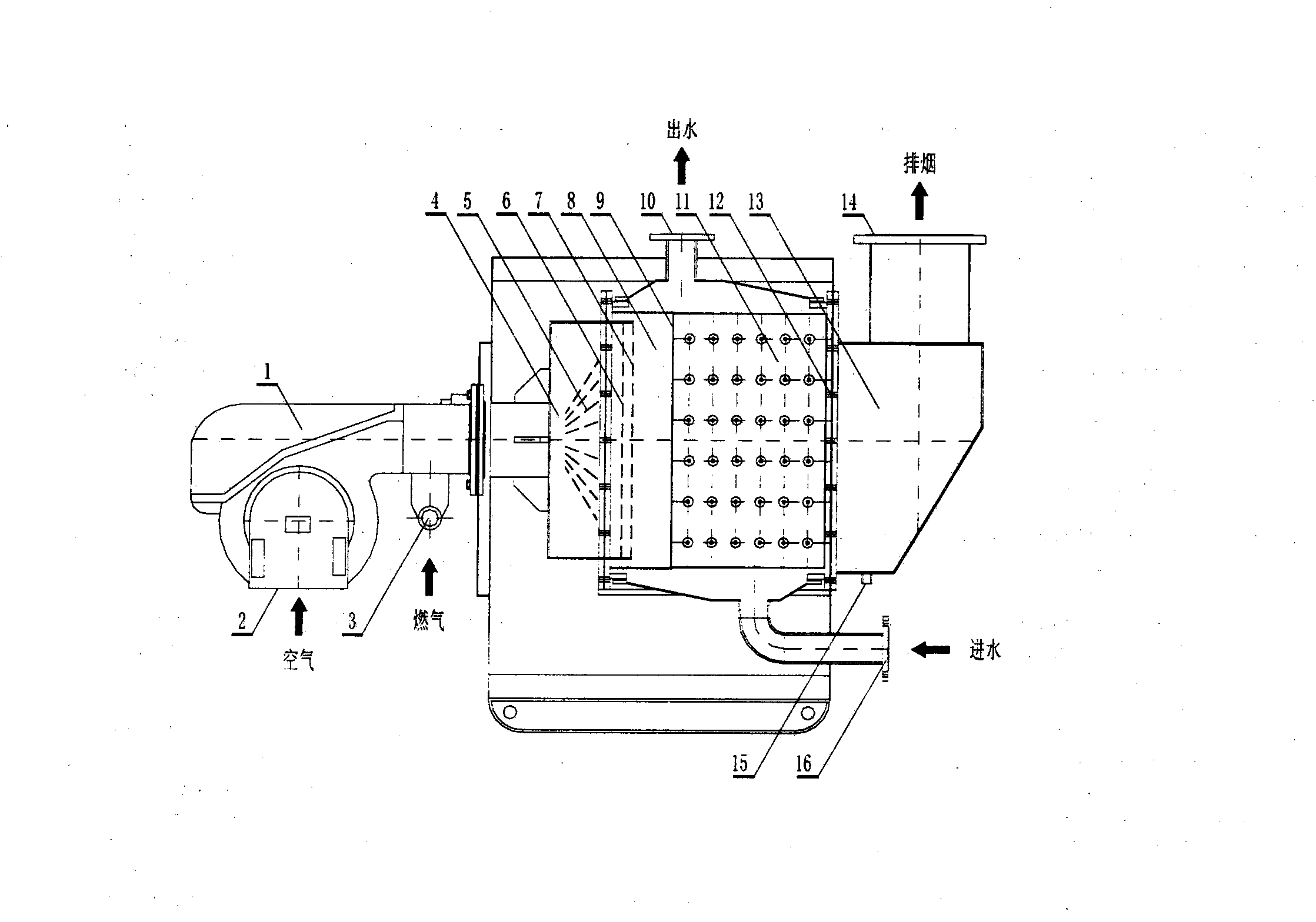

[0009] In the figure, the air intake fan 1 sucks in air through the air inlet 2, and the gas entering with the gas inlet 3 forms a mixed gas in the air and gas premixing chamber 4. The mixed gas is sprayed evenly through the gas distributor 5, and then further stabilized by the gas pressure stabilizing plate 6. The pressure-stabilized mixed gas is discharged through the surface of the porous metal combustion plate 7 and ignited on the surface of the porous metal combustion plate. The ignited mixed gas burns in the combustion chamber 8, and generates a large amount of heat after the mixed gas burns to form high-temperature flue gas. The high-temperature flue gas enters the flue gas-water plate heat exchanger 9 from the smoke-water plate heat exchanger, and enters the smoke-water plate heat exchanger 11. In the smoke-water plate heat exchanger, the high-temperature flue gas exchanges heat with water, and the temperature of the high-temperature flue gas drops , the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com