Detachable laminated plate heat exchanger

A heat exchanger, flat-stacked technology, which is applied in the field of micro-plate heat exchangers, can solve the problems of inability to remove inner cavity fouling through maintenance and maintenance measures, short service life of flat-stacked plate heat exchangers, and poor flow of heat exchange medium. Smooth and other problems, to achieve the effect of simple detachable structure, high production efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

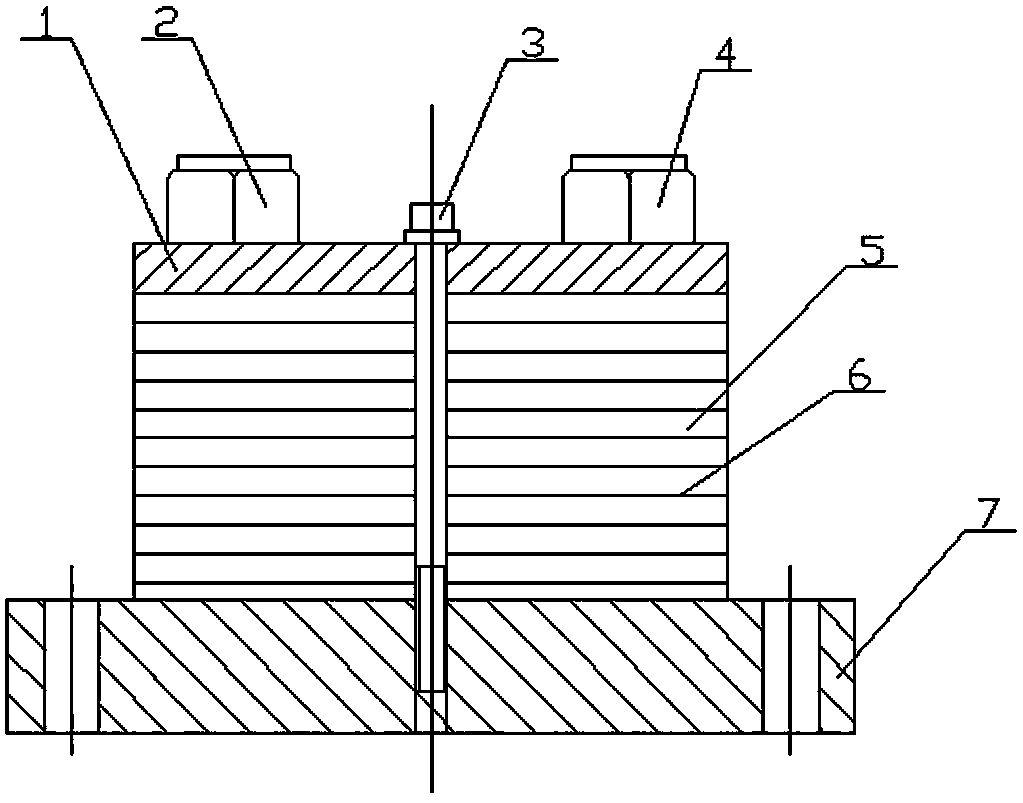

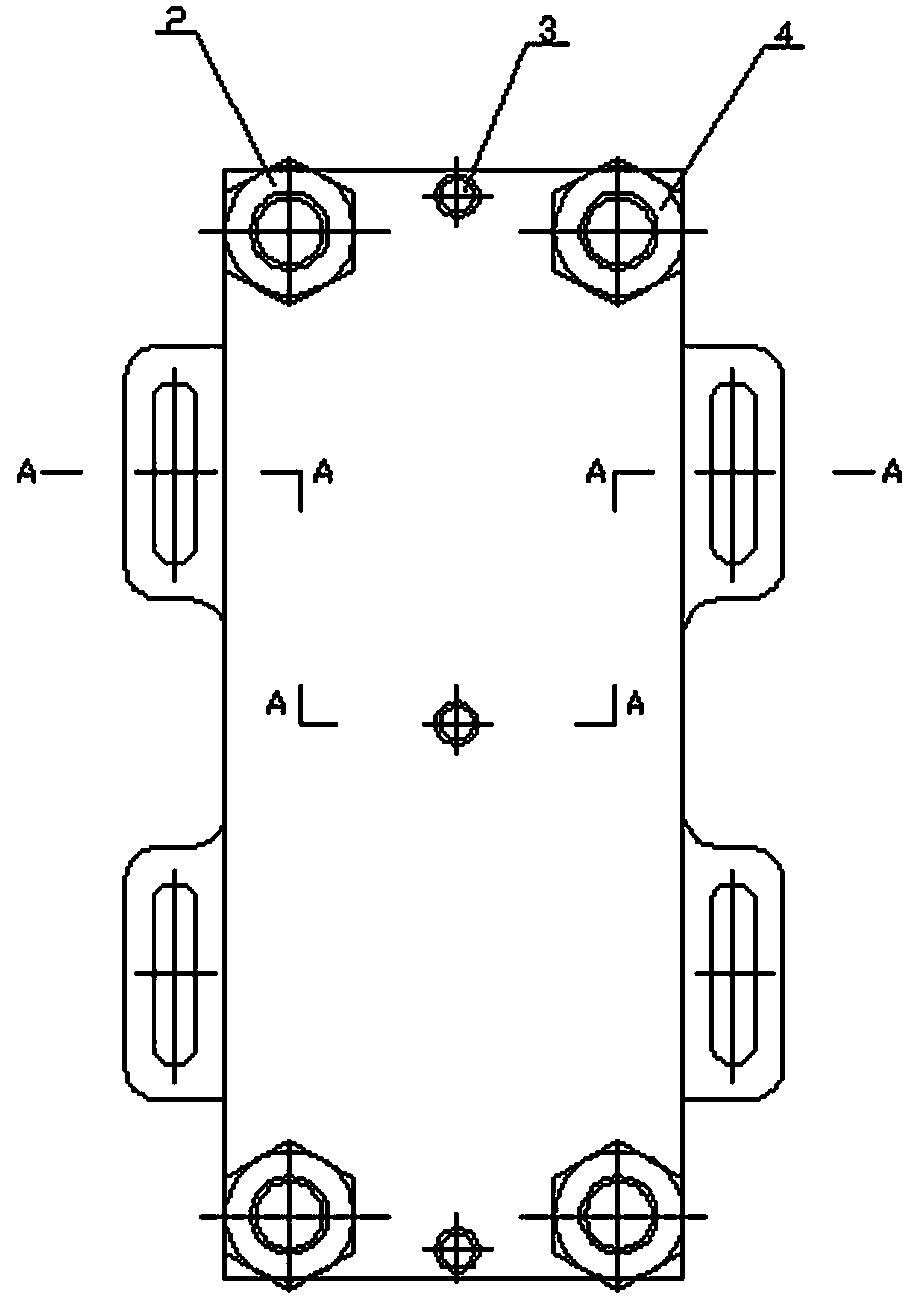

[0014] figure 1 Shown is a detachable flat-stack heat exchanger, example for use in the petrochemical industry. The heat exchange medium is oil-water. It includes a pressure plate 1, an inlet joint 2, a bolt 3, an outlet joint 4, a heat exchange plate 5, a sealing strip 6 and a bottom plate 7. The pressing plate 1 is located on the top layer, and it is a rectangular plate with screw holes communicating with the passages of the heat exchange plate 5 at the four corners. The inlet joint 2 and the outlet joint 4 are both threaded joints with built-in through holes, which are respectively paired and screwed into the screw holes at the four corners of the pressure plate 1 to prepare for introducing the heat exchange medium and the heat exchange medium respectively. The base plate 7 is a flat plate supporting the pressing plate 1, and is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com