Automatic combination-fireworks fuse inserting method and device

A combination of fireworks and automatic technology, applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of large deviation of the thread hole position, high production cost, safety accidents, etc., to ensure the safety of enterprise property, high degree of automation, guarantee The effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

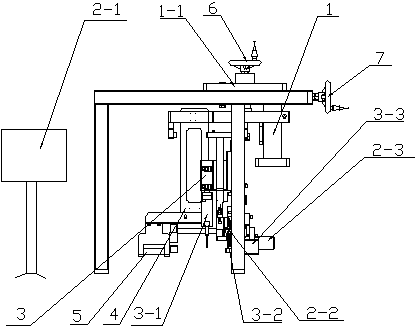

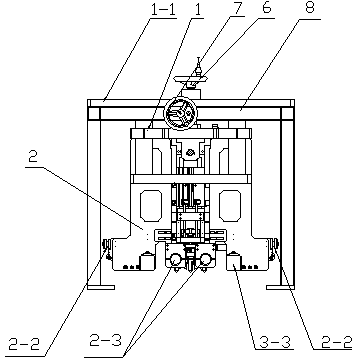

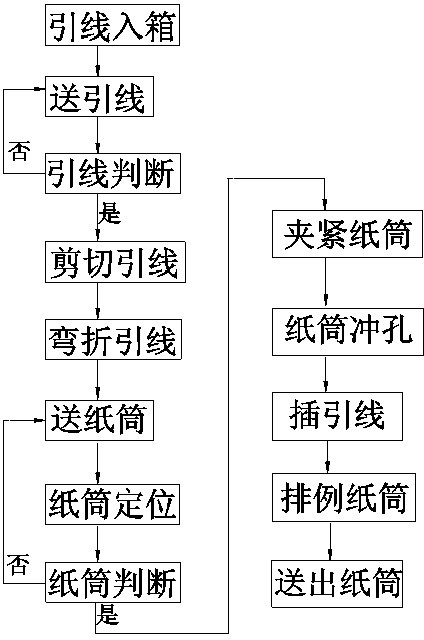

[0035] as attached image 3 Shown: a method for automatic insertion and introduction of combined fireworks, its process includes the following steps:

[0036] a. Put the coil lead wire in the explosion-proof lead wire storage box;

[0037] b. Feed one end of the lead wire through the stepping motor of the lead wire feeding part;

[0038] c. Use the sensor to judge whether the lead wire is in the specified position, if yes, proceed to the next step, if not, restart the stepping motor wire feeding part of the lead wire feeding part;

[0039] d. Pneumatic scissors cut the lead wire to the required length;

[0040] e. Bend the cut lead into a U shape;

[0041] f. Start the paper feeding tube device, and feed the paper tube into the combined fireworks automatic insertion device;

[0042] g. Use three rollers that can move up and down to position the paper tube that inserts the lead wire

[0043] h. Use the sensor to judge whether the paper tube is in the specified position, if...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com