A fully waterproof eddy current sensor probe

A technology of eddy current sensor and compression screw sleeve, which is applied to instruments, electric devices, electromagnetic means, etc., can solve the problems of insufficient front-end sealing, water inflow, no waterproof device, etc., so as to maintain long-term reliable operation. , Reliable sealing effect, the effect of efficient sealing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

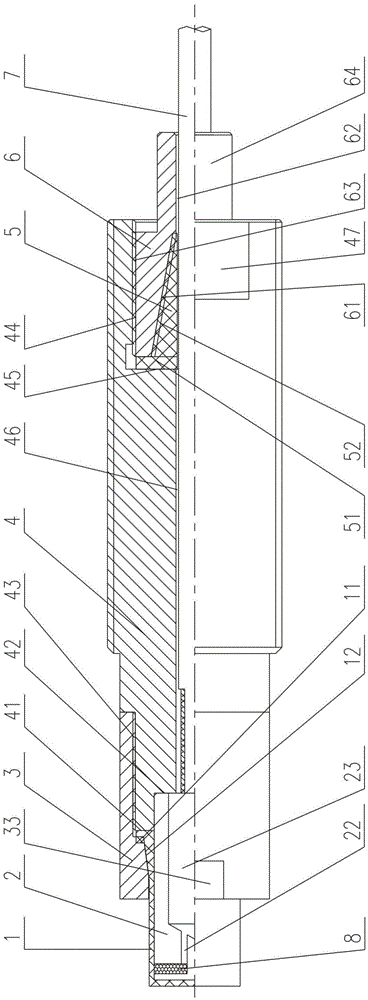

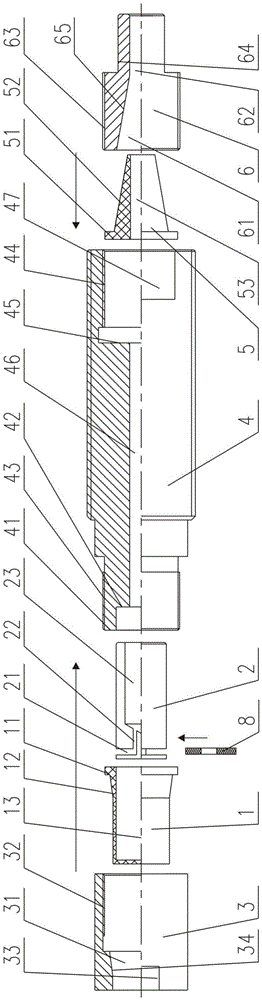

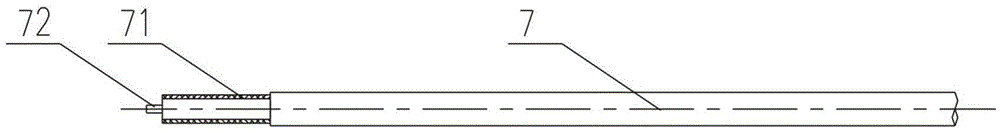

[0019] Such as figure 1 and figure 2 As shown, the full waterproof eddy current sensor probe of the present invention includes a probe housing 4, a skeleton 2, a coil 8, a blind sealing sleeve 1, a front compression screw sleeve 3, a rear compression screw sleeve 6 and a tapered sealing ring 5, The skeleton 2, the coil 8 and the blind sealing sleeve 1 are all mounted on the front end of the probe housing 4 (that is, the left end in the figure), the front end of the blind sealing sleeve 1 is sealed and the rear end is open, and the rear end of the blind sealing sleeve 1 extends outward from the circumference The front brim ring 11 is formed, the outer peripheral surface of the front section of the probe housing 4 is provided with a housing external thread 43, the outer peripheral surface of the rear section of the blind seal sleeve 1 is a front outer tapered surface 12 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com