A connection structure between a low-voltage terminal head and a conductive rod of an oil-immersed transformer

An oil-immersed transformer and connection structure technology, which is applied in the field of transformer manufacturing, can solve the problems of large lengths of compression nuts and exposed parts of conductive rods, long lengths of conductive rods, and high costs, and achieve the goals of saving raw materials, reliable installation, and reduced length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

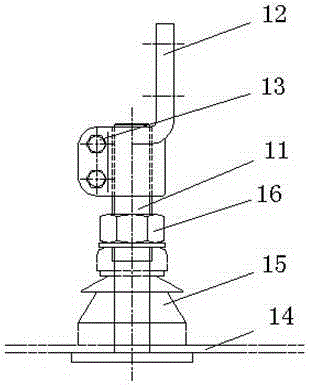

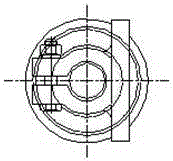

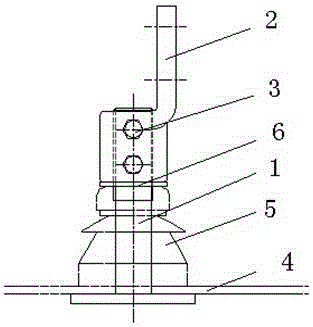

[0015] A connection structure between an oil-immersed transformer low-voltage terminal and a conductive rod, see image 3 and Figure 4 , the connection structure includes a conductive rod 1 and a terminal 2 . The upper part of the conductive rod is threaded, and the lower part is a polished rod. There are two mounting holes radially penetrating on the upper part of the conductive rod, and a terminal hole matching the mounting hole is provided on the terminal, and a screw thread suitable for the upper part of the conductive rod is also provided in the terminal. It is threadedly fitted on the conductive rod, and locked by two fastening bolts 3 arranged in the installation hole and the terminal hole; the terminal removes the clamping part of the traditional installation fastening bolt. An adjusting gasket 6 is sleeved on the conductive rod, and the adjusting gasket is located below the wiring head. The connecting head compresses the porcelain bottle 5 on the case cover 4 by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com