Cathode filament and cathode lamp

A cathode and filament technology used in cathode lamps. It can solve the problems of poor thermal uniformity of the filament assembly, uneven pitch, and influence on cathode emission, and achieve the effects of less on-off times of the filament, improved winding stability, and good winding stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

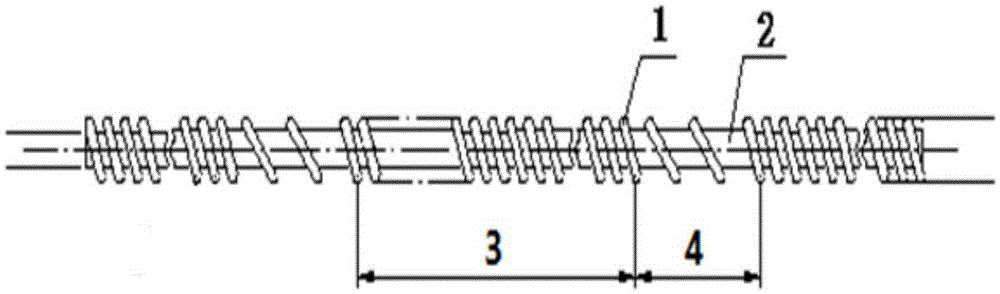

[0036] The present invention also provides a method for preparing a cathode filament, which includes the process of continuously winding a tungsten-rhenium wire 1 on the outer periphery of a molybdenum wire 2, wherein the tungsten that is continuously wound on the outer periphery of the molybdenum wire 2 The rhenium wire 1 includes a first winding circle 3 and a second winding circle 4, the first winding circle 3 is 45-55 turns, and the distance between two adjacent turns is 0.2-0.3mm, and the second winding circle 4 is 1-4 turns, the distance between two adjacent turns is 1-4mm, and the distance between the first winding circle 3 and the second winding circle 4 is 0.5-2mm.

[0037] Preferably, the first winding circle 3 is 48-53 turns, and the distance between two adjacent turns is 0.23-0.27mm; the second winding turn 4 is 1-3 turns, and the distance between two adjacent turns is 0.23-0.27mm. The distance between them is 1-3 mm, and the distance between the first winding circ...

Embodiment 1

[0049] Carry out the first winding of tungsten-rhenium wire 1 with the travel speed of molybdenum wire 2 as 15mm / min and the winding speed of tungsten-rhenium wire 1 as 131mm / min, then, change the winding speed of tungsten-rhenium wire 1 into 50mm / min for tungsten A second winding of rhenium wire 1 yielded a filament (17.05 mm in length). Its structure is as follows: the number of turns of the first winding circle 3 is 49 turns, the interval between two adjacent turns is 0.25mm, the number of turns of the second winding turn 4 is 2 turns, and the interval between two adjacent turns is 2mm , the distance between the first winding circle and the second winding circle is 0.8 mm.

Embodiment 2

[0051] Carry out the first winding of tungsten-rhenium wire 1 with the travel speed of molybdenum wire 2 as 15mm / min and the winding speed of tungsten-rhenium wire 1 as 133mm / min, then, change the winding speed of tungsten-rhenium wire 1 into 50mm / min for tungsten Second winding of rhenium wire 1, resulting in a filament (16.96 mm in length). Its structure is as follows: the number of turns of the first winding circle 3 is 51 turns, the interval between two adjacent turns is 0.26 mm, the number of turns of the second winding turn 4 is 2 turns, and the interval between two adjacent turns is 1.5 mm. mm, the distance between the first winding circle and the second winding circle is 0.7 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com