Nail-carrying disc structure of circumcision stapler

A technology of suture staples and staplers, which is applied in the field of medical surgical instruments, can solve the problems of long staple removal time, troublesome staple removal, and increased work intensity of medical staff, so as to prevent infection and reduce operation intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

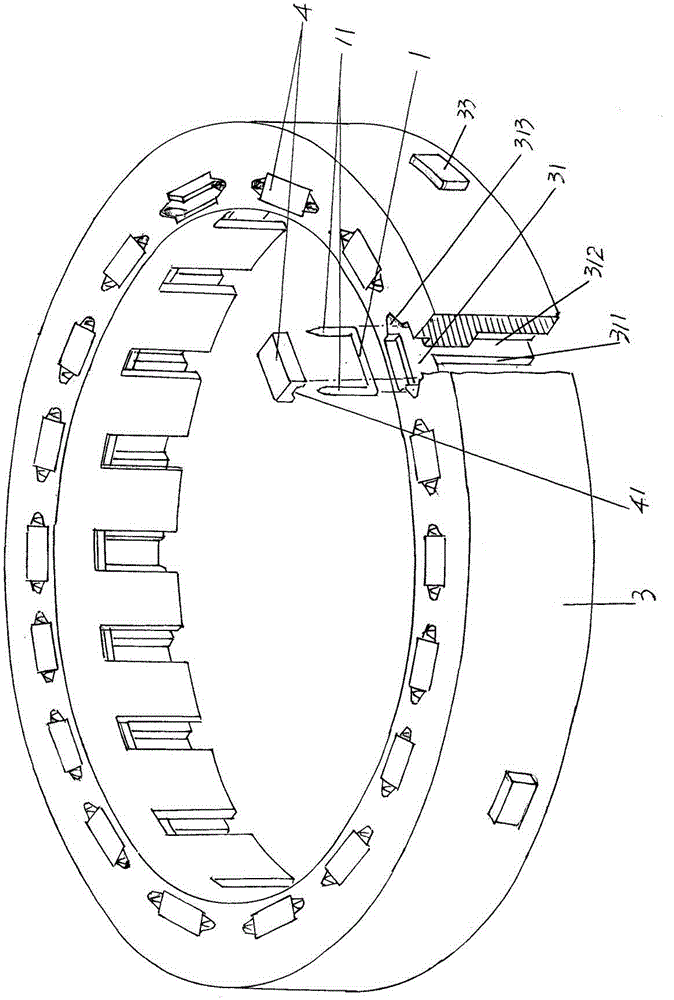

[0029] See figure 1 , provides a nail-loaded tray body 3, the overall shape of the nail-loaded tray body 3 is in the shape of a ring, and preferably plastic molding is used, on the nail-loaded tray body 3 and around the nail-loaded tray body 3 The circumferential direction of the nail loading chamber 31 is formed in a spaced state, and the nail loading chamber 31 penetrates from the upward side of the nail loading tray body 3 to the downward facing side, that is to say, from the height direction of the nail loading tray body 3 side ( figure 1 The upper side of the position state shown) through to the other side ( figure 1 The lower side of the shown position state), and the staple 1 is accommodated in the nail-carrying cavity 31 in an inserting manner, and the staple 1 has a pair of staple feet 11 for figure 1 The position state shown is an example, with a pair of staple feet 11 facing upwards. Depend on figure 1 It can be seen from the schematic diagram that the over...

Embodiment 2

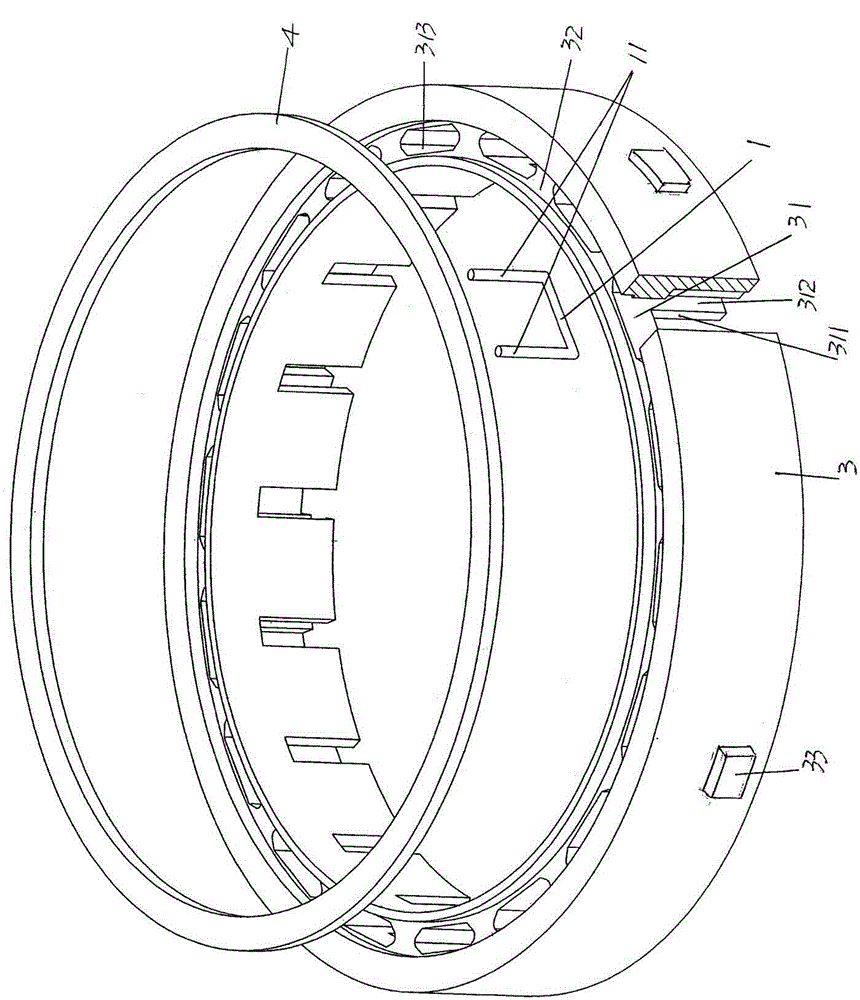

[0038] See figure 2 ,Should figure 2 Another structural form of the aforementioned staple pad 4 is shown, specifically, the structure of the staple pad 4 is an annular staple pad washer. Since the staple pad 4 is an annular staple pad washer, the upper side of the aforementioned staple tray body 3 (with figure 2 The shown position is taken as an example) and a washer groove 32 is recessed around the circumferential direction of the staple tray body 3 at a position corresponding to the nail loading cavity 31 , and the staple washer is embedded in the washer groove 32 .

[0039] In the present embodiment, the width of the aforementioned staple back washer is adapted to the width of the washer groove 32, and the thickness is adapted to the depth of the washer groove 32, for example, the width of the washer groove 32 is 3 mm, and the depth is 1 mm. , then the width of the staple pad gasket is also 3 mm, and the thickness is 1 mm. All the other are the same as the description...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com