Repairing needle for teflon coating and repairing method

A Teflon, coating technology, applied in the direction of coating, device for coating liquid on the surface, special surface, etc., can solve the problem of uncontrollable amount of powder and repairing process, workers are easily scalded, and the flatness of the coating is poor. and other problems, to achieve the effect of easy operation and control, simple structure and high qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the drawings and examples.

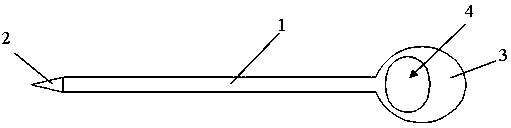

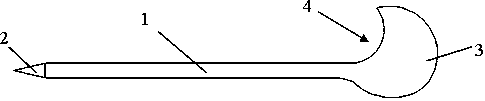

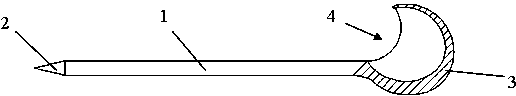

[0029] figure 1 It is a schematic diagram of the front structure of the Teflon-coated repair pin of the present invention; figure 2 It is a schematic diagram of the side structure of the Teflon-coated repair pin of the present invention; image 3 It is a sectional view of the powder scoop part of the Teflon-coated repair needle of the present invention.

[0030] like Figure 1 to Figure 3 As shown, the Teflon-coated repair needle of the present invention includes a needle shaft 1 constituting the main body of the repair needle, one end of the needle shaft forms a sharp needle point 2, and the other end of the needle shaft is set as a powder scoop 3.

[0031] The powder scoop has a semi-enclosed structure, and a space for containing powder is formed inside the powder scoop wall. The opening 4 of the powder scoop is arranged on the powder scoop wall close to the need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com