Multi-dimensional gearing for cleaning equipment

A transmission device and cleaning equipment technology, which is applied in the directions of cleaning methods using liquids, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of inconvenient production and assembly, complicated use functions, and no multi-dimensional transmission device and multi-dimensional transmission system. To achieve the effect of ensuring sealing performance, preventing high temperature transmission, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

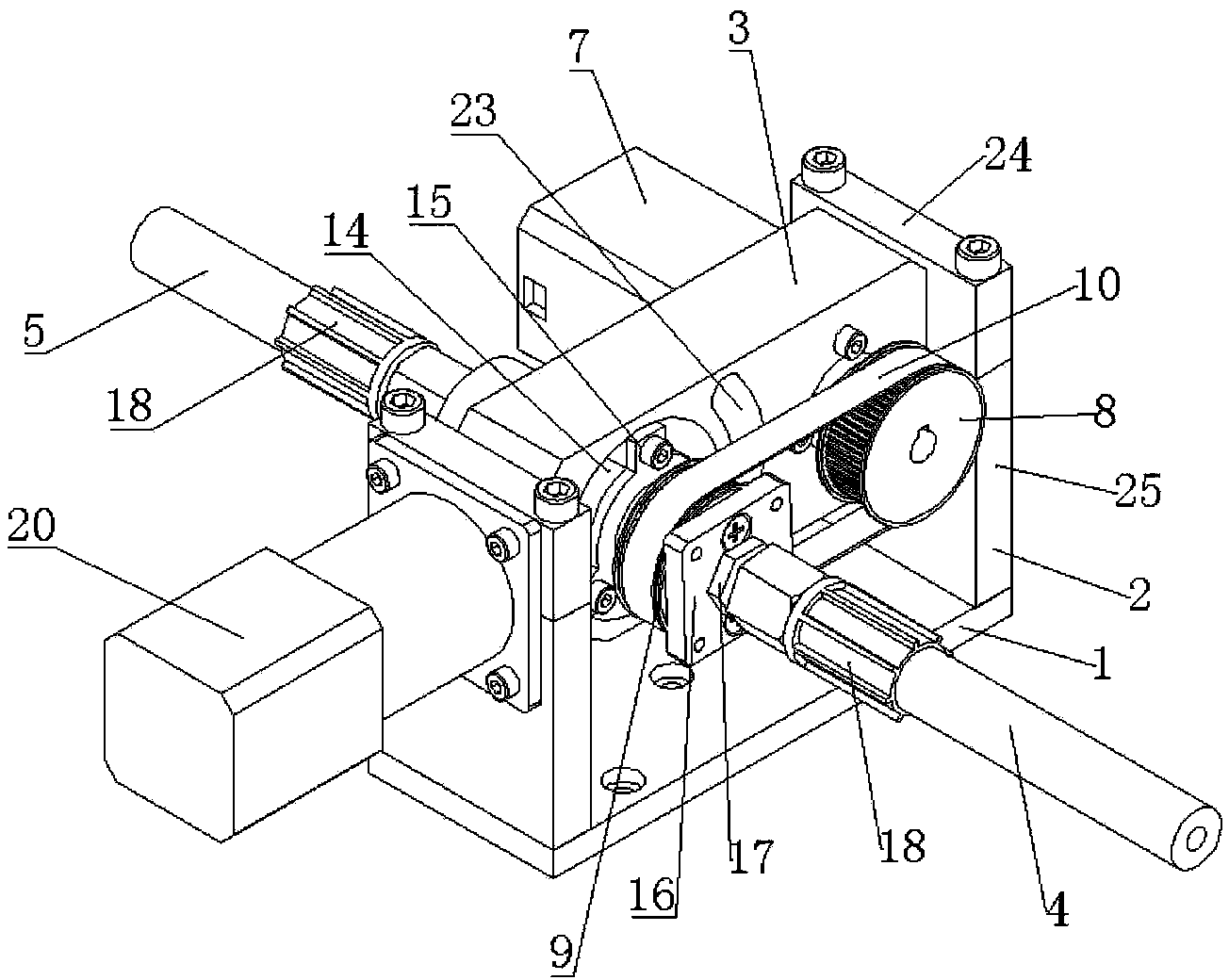

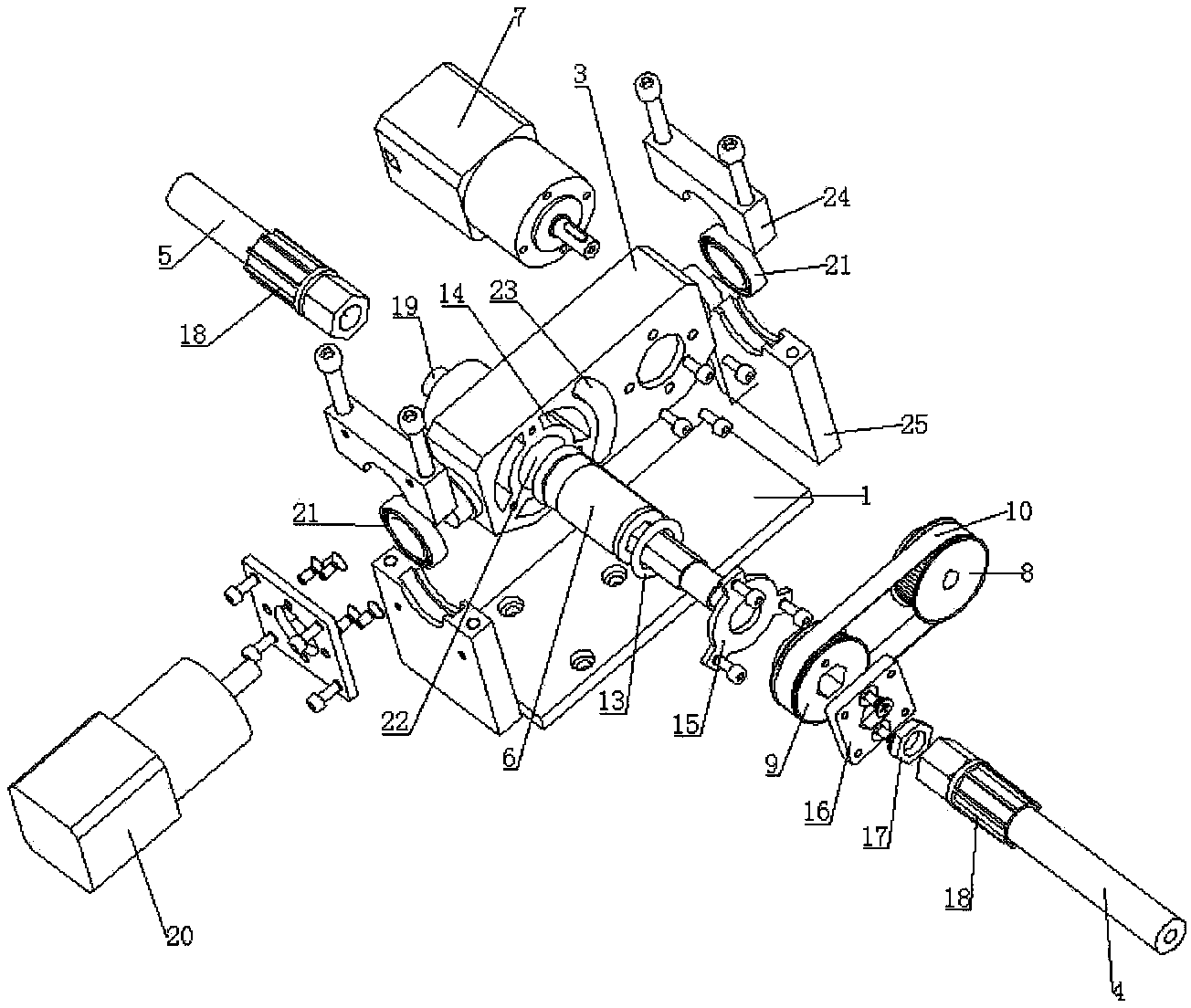

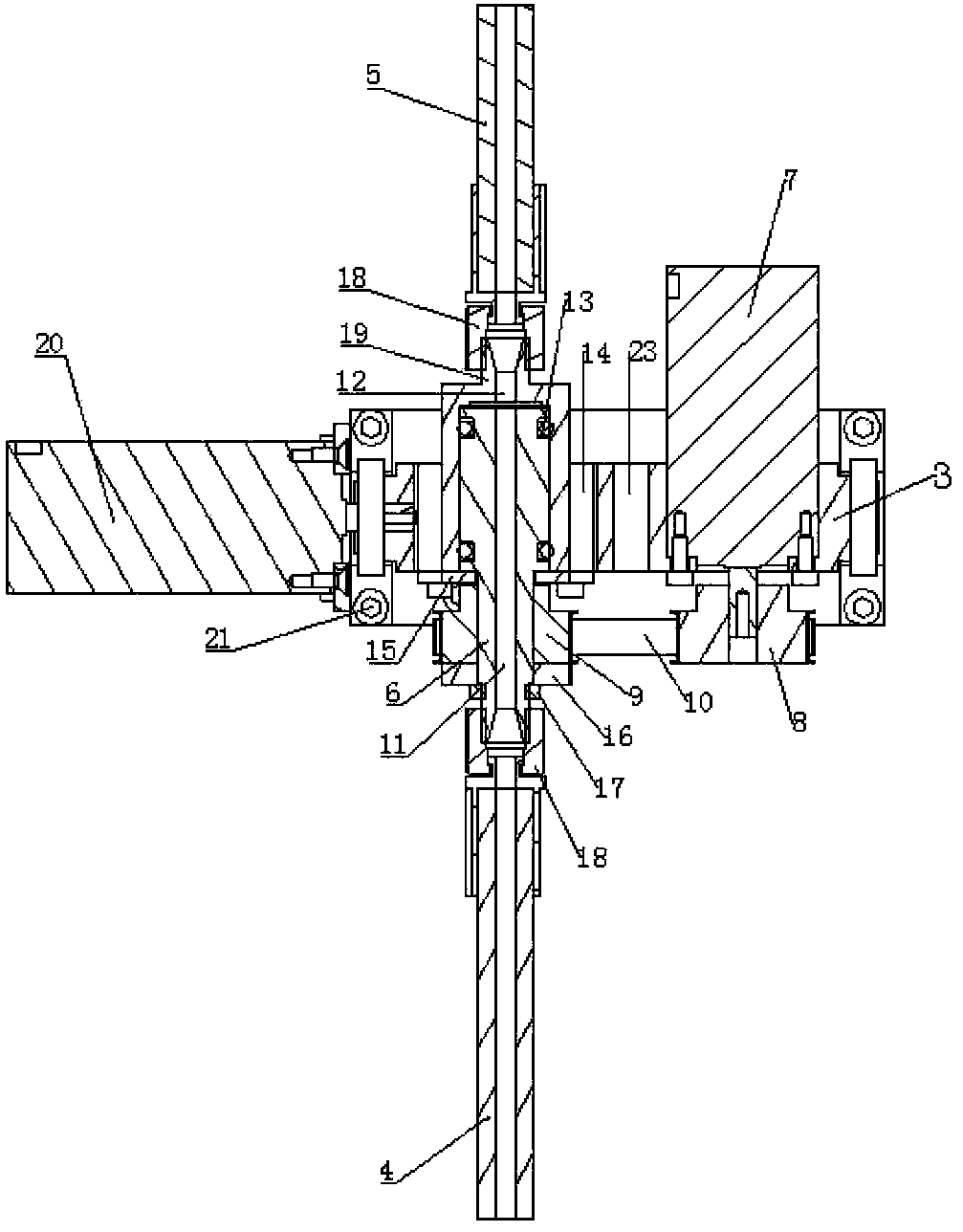

[0020] Such as Figures 1 to 3 As shown, the multi-dimensional transmission device for cleaning equipment proposed by the present invention includes: a bottom plate 1, two bearing seats 2 relatively arranged at the left and right ends of the bottom plate 1, and two ends of the two bearing seats 2 are respectively rotatable. Seat 3, horizontally communicated with the outlet pipe 4 and inlet pipe 5 arranged on the front and rear sides of the spray rod rotating seat 3, the lateral rotation device arranged between the outlet pipe 4 and the spray rod rotating seat 3, and the bearing seat 2 and the spray rod The longitudinal rotation device between the swivel seats 3 and the horizontal rotation device located at the bottom of the bottom plate 1; the longitudinal rotation device pushes the spray bar swivel seat 3 to rotate along the axis of both ends of the spray bar swivel seat 3, and the horizontal rotation device pushes the outlet pipe 4 along the outlet pipe 4 axis rotation, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com