Working machine with both laser output and inkjet printing functions

A technology of inkjet printing and working machines, applied in typewriters, printing, etc., can solve problems such as work efficiency, process discounts, and cost increases, and achieve the effects of improving work efficiency and production efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

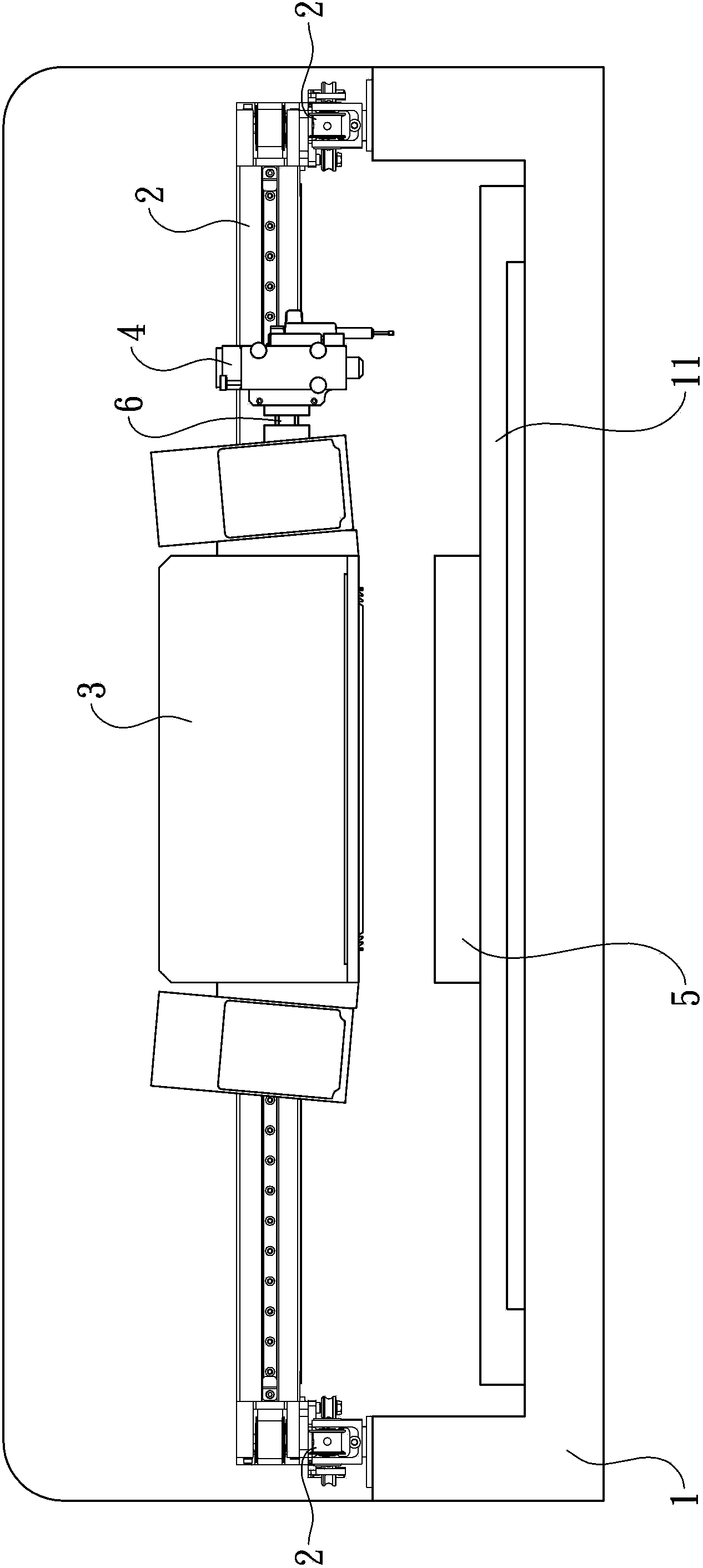

[0016] see figure 1 , the content of the drawing is an embodiment of the working machine with both laser output and inkjet printing in the present invention, which consists of a working machine 1, a set of working tracks 2, an inkjet module 3, a laser output module 4 and a Pivot device 6 is formed.

[0017] The working platform 1 is provided with a processing platform 11 for a workpiece 5 to be placed on, and the working track 2 is arranged on the working platform 1 and faces above the processing platform 11 .

[0018] The laser output module 4 is combined on the working rail 2, and through the control of the working machine 1, it can generate horizontal and vertical displacements above the processing table 11 for engraving or cutting patterns on the workpiece 5.

[0019] The inkjet module 3 is combined on the working track 2, and is combined with the laser output module 4 through the pivot joint device 6. Driven by the laser output module 4, the horizontal and vertical displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com