Multi-proportion dividers

A technology of compasses and compasses legs, which is applied to circular curve plotters, printing, writing utensils, etc. It can solve the problems of low precision, labor and time, and achieve the effect of ensuring the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

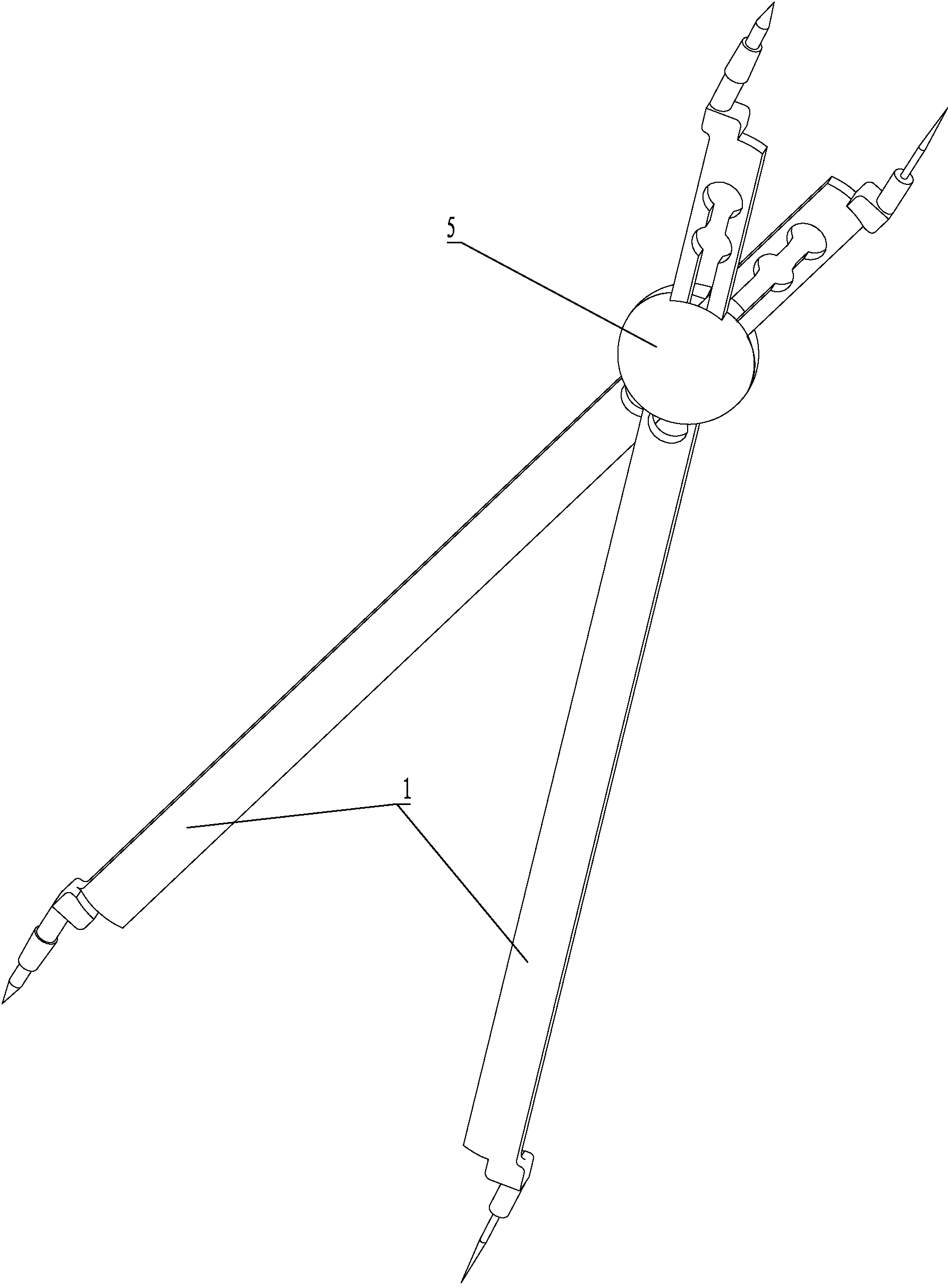

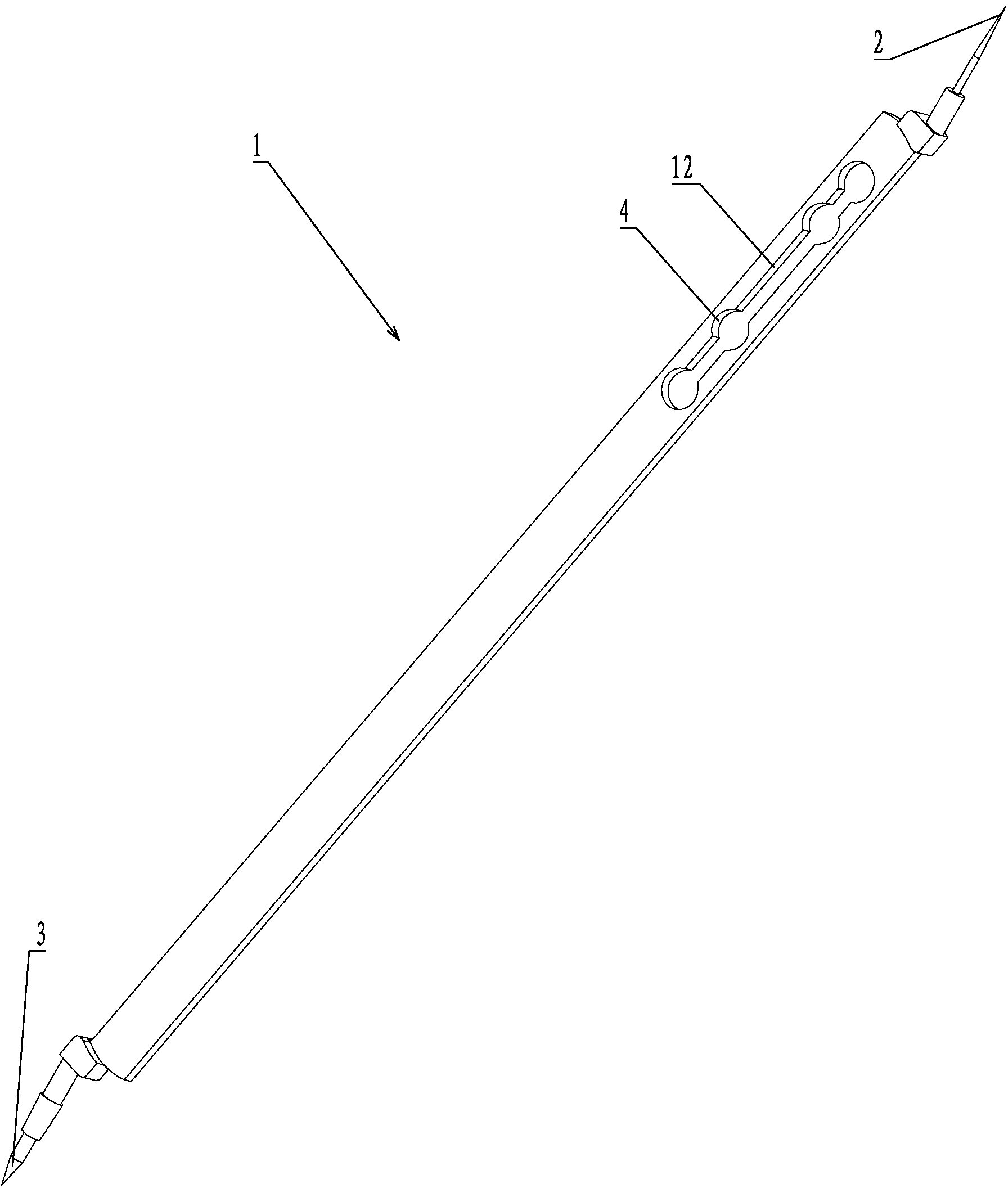

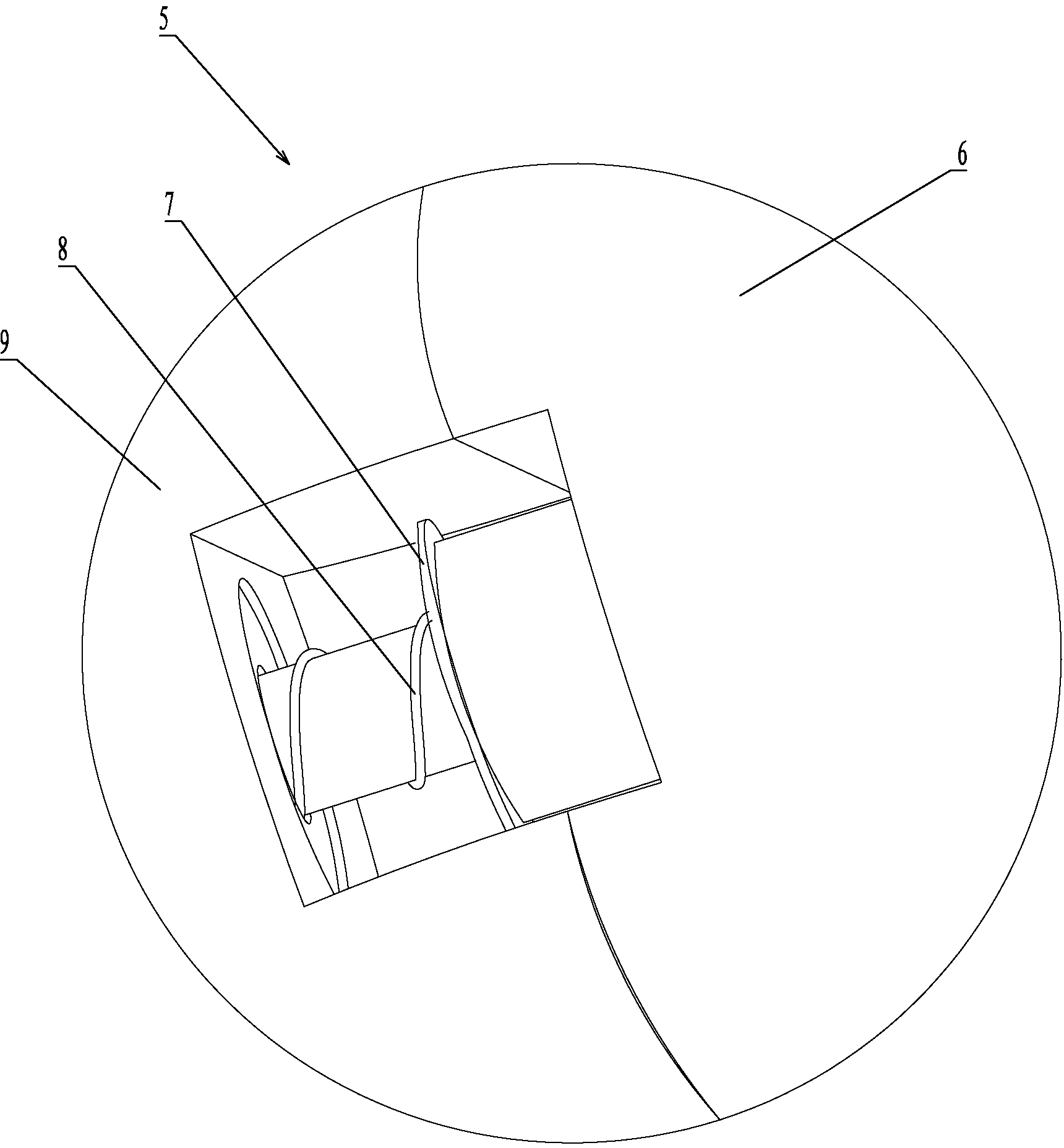

[0024] Such as Figure 1 to Figure 4 As shown, the present embodiment includes two compass legs 1, and a compass needle 2 and a pencil lead 3 are arranged at both ends of each compass leg 1 respectively, and a plurality of fixed ratio holes 4 are arranged between the compass needle 2 and the pencil lead 3 of the compass leg 1 , when carrying out scale drawing, to realize the rapid and accurate determination ratio of various proportions and carry out scale drawing; Pin sliding groove 12 is arranged between fixed ratio hole 4, and the groove width of pin sliding groove 12 is less than the diameter of fixed ratio hole 4 , to ensure that the radial position between the coupling device 5 and the two compass legs 1 is relatively stable, and only when the ratio needs to be changed, the coupling device 5 can slide along the pin sliding groove 12 to realize switching of different ratios; the coupling device 5 wears into the fixed ratio hole 4 corresponding to the two compass legs 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com