A method for improving the damping performance of high-strength iron-manganese-based damping alloy

A damping alloy, iron-manganese-based technology, applied in the field of damping alloys, can solve the problem of low damping performance, achieve the effects of improving damping performance, weakening resistance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

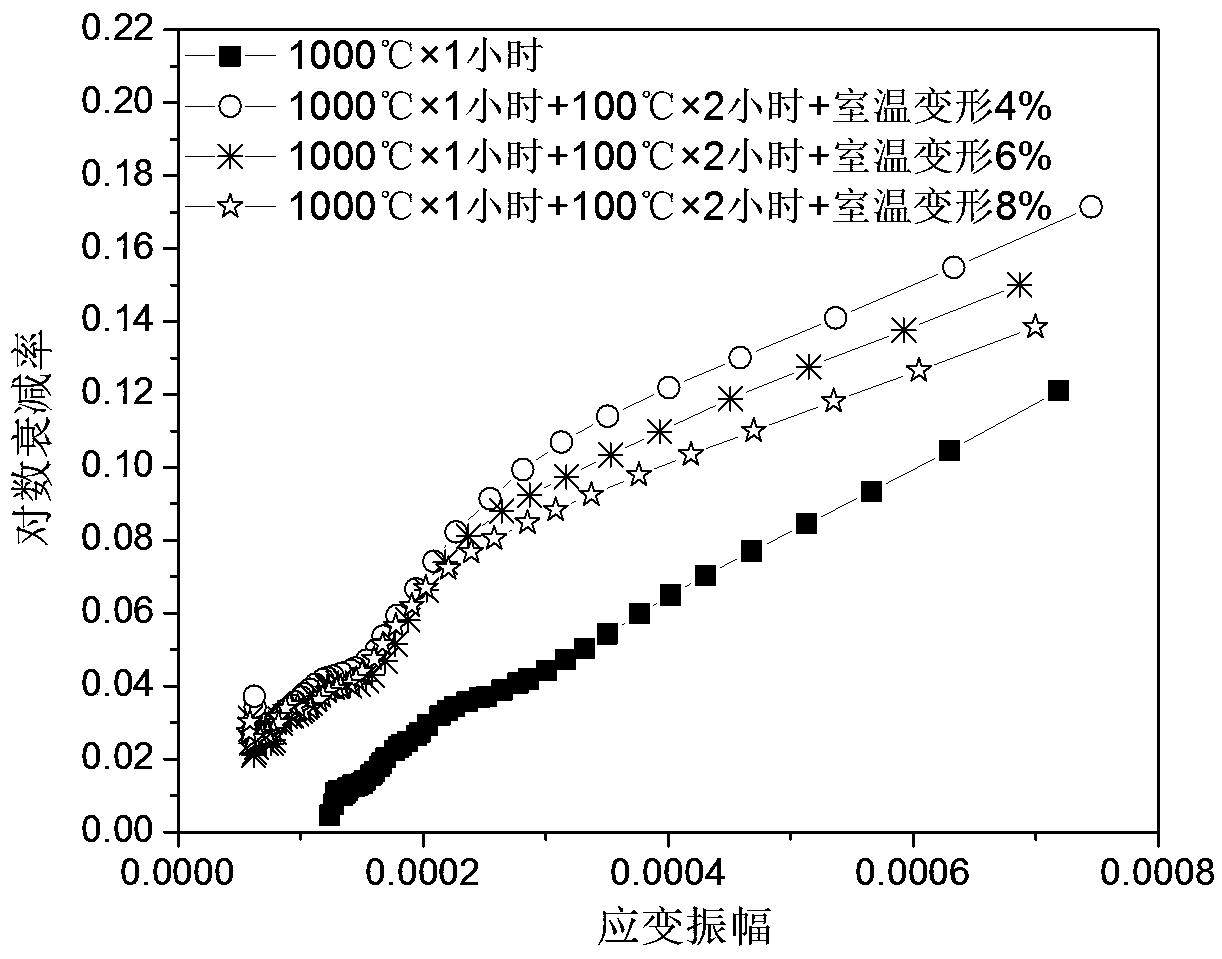

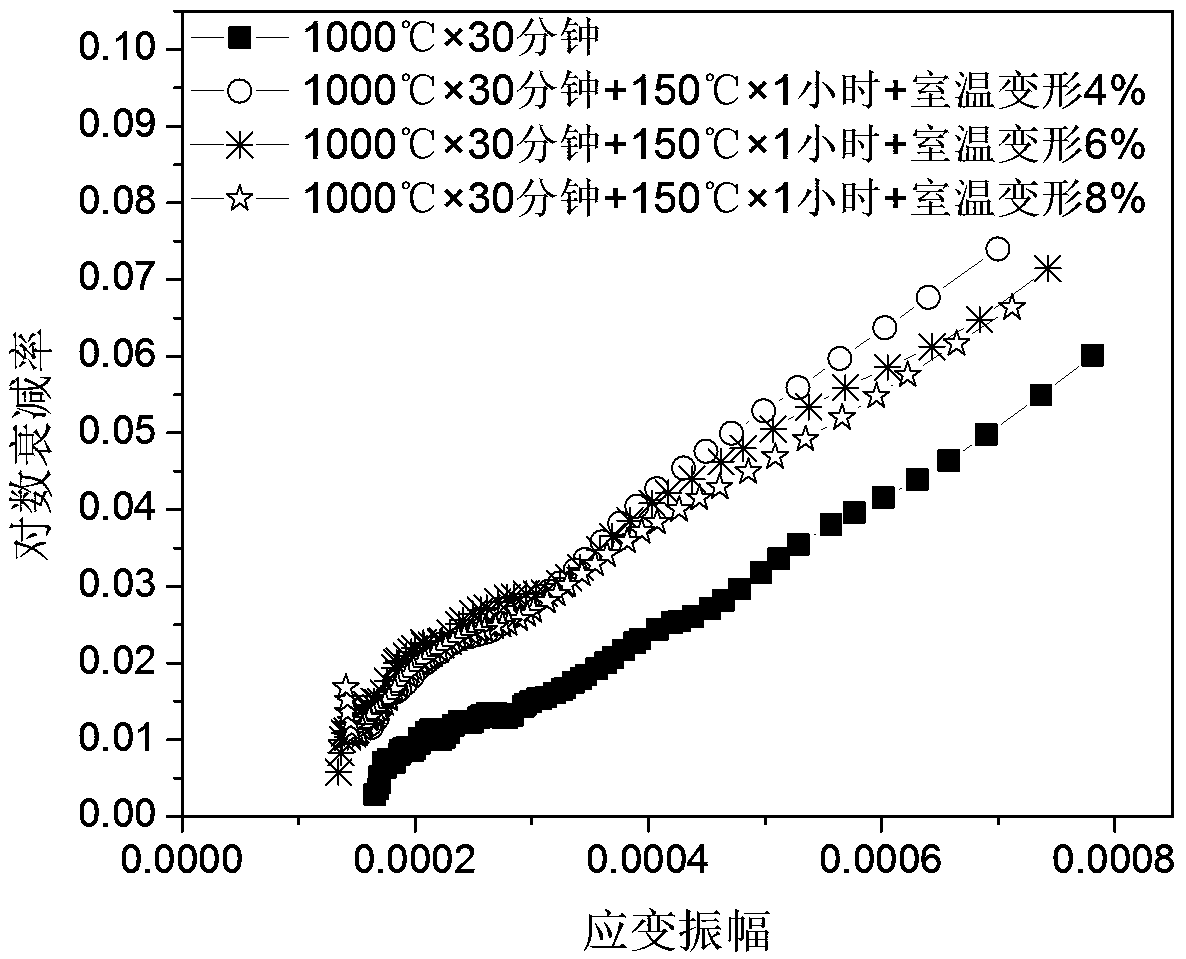

[0013] Embodiment two. The weight percentage content of each element of the Fe-17.82Mn-0.09C damping alloy is as follows: Mn17.82%, C0.09%, the rest is Fe and unavoidable impurities. The specific treatment method of the alloy is as follows: the alloy is solution treated at 1000°C for 30 minutes, then aged at 150°C for 1 hour, and finally deformed at room temperature by 4% to 8%. In order to prove that the present invention can significantly improve the damping performance of high-strength iron-manganese-based damping alloys, especially the damping performance at low strain amplitudes, an alloy that has only been solution treated at 1000°C for 30 minutes is used as a comparative example. According to the provisions of GB / T13665-1992 "Metal damping material damping ability test method torsional pendulum method and bending resonance method", the damping performance of the alloy is tested by the JN-1 Gurley inverted torsion pendulum internal friction tester. figure 2 The damping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com