Decoration anti-skid wallboard

A wallboard and anti-slip technology, which is applied in the field of building decoration materials, can solve the problems of affecting the overall appearance, reducing the compression resistance, and high production costs, and achieves the effects of reducing the weight of the board body, good compression resistance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

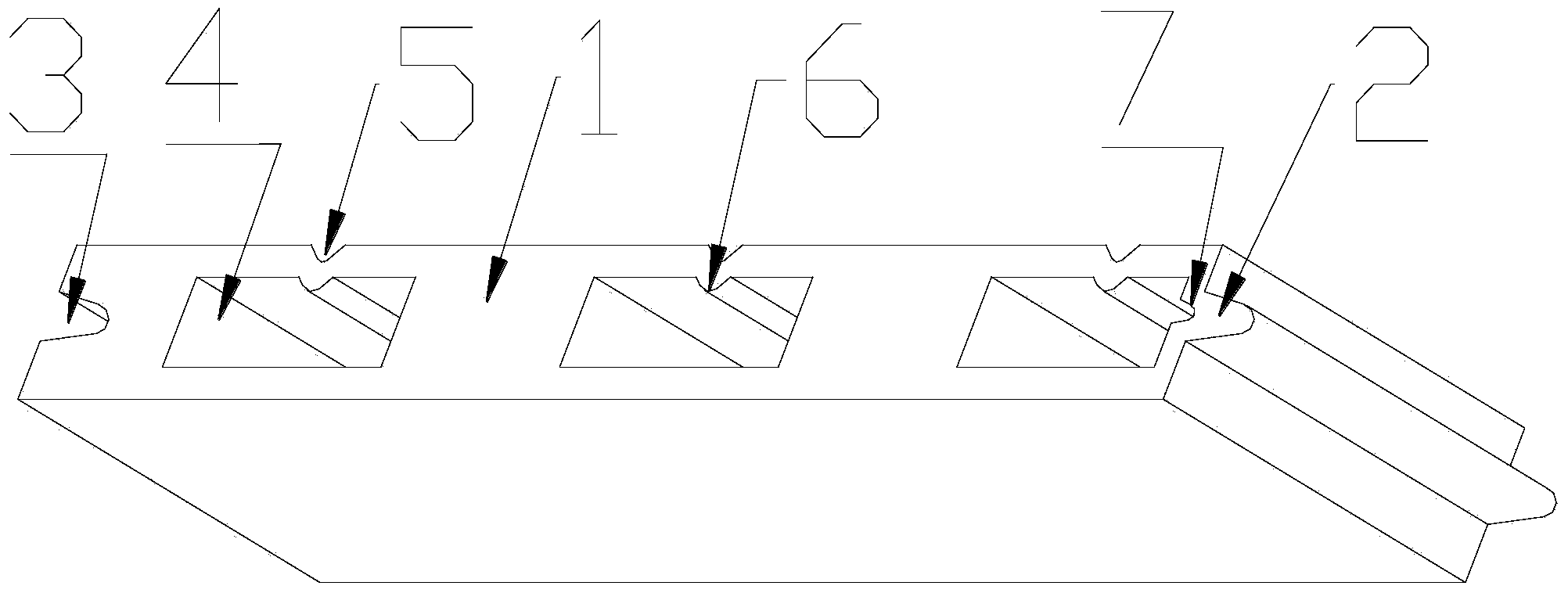

[0012] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a decorative anti-slip wallboard proposed by the present invention.

[0013] refer to figure 1 , the present invention discloses a decorative anti-slip wallboard, comprising a board body 1, the board body 1 includes a front face, a rear face, a left face, a right face, an upper face and a lower face, and the inside of the board body 1 has at least two The through hole 4, the right side protrudes to the right to form a raised portion 2, the left side is recessed to the right to form a groove portion 3 that can cooperate with the raised portion 2, the surface of the raised portion 2 and / or the surface of the groove portion 3 Has a buffer layer.

[0014] The right inner wall of the rightmost through hole 4 is partially recessed to the right to form a first groove 7, the first groove 7 extends from the front to the rear, and the first groove 7 is formed on the right side. A projection is within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com