Top-coal Gas Drainage System on Top Coal in Fully Mechanized Caving Face

A technology for fully-mechanized caving face and gas drainage, which is applied in gas discharge, mining equipment, earth-moving drilling, etc., can solve the problems of long gas drainage time, limitation of drilling length, production and excavation impact, etc., and achieves economical and Significant social benefits, increase the operating rate and output, and reduce the effect of gas overrun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

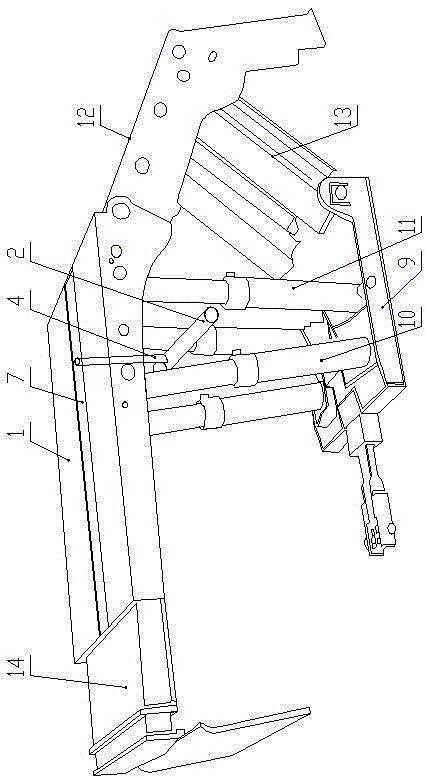

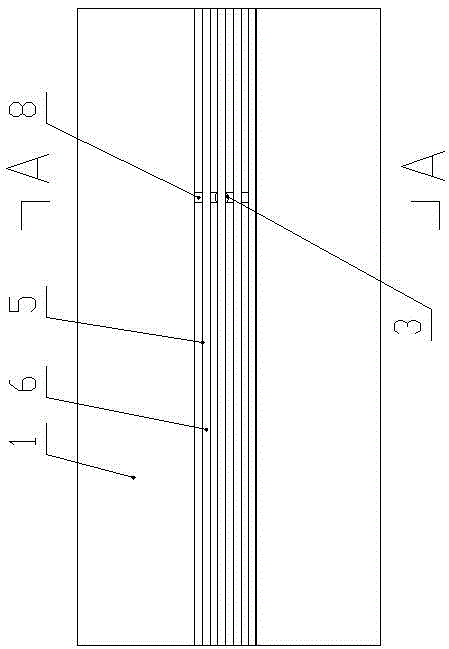

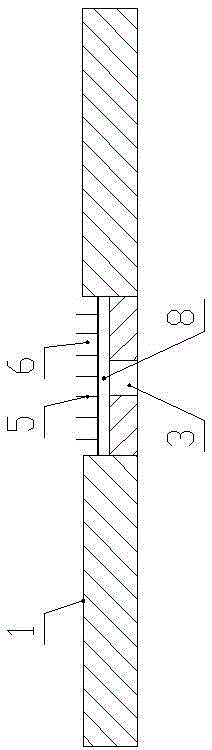

[0039] Such as figure 1 , figure 2 and image 3 As shown, the top-coal and gas extraction system of the present invention includes a hydraulic support, a top beam 1 is provided on the top of the hydraulic support, and a groove 7 is provided in the middle of the top beam 1 along the length direction. An overhead main pipe 2 is provided, and a drainage hole 3 communicating with the groove 7 is arranged on the top beam 1 , and the extraction hole 3 and the overhead main pipe 2 are connected through an overhead branch pipe 4 .

[0040] The top beam 1 can be made in one piece, or a reinforcing convex plate can be set on the left and right sides of the top beam 1, and a groove 7 with a width of about 300 mm and a depth of about 30 mm is formed between the upper surface of the top beam 1 and the two reinforcing convex plates. It plays the role of less air leakage in the extraction, and the concave area is a loose air-permeable area, and the extraction hole 3 is arranged at a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com