Magnetic drive pump with pressure sensor

A technology of pressure sensor and magnetic pump, applied in the field of magnetic pump, can solve the problems of wasting water source, wasting electric energy, pump damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

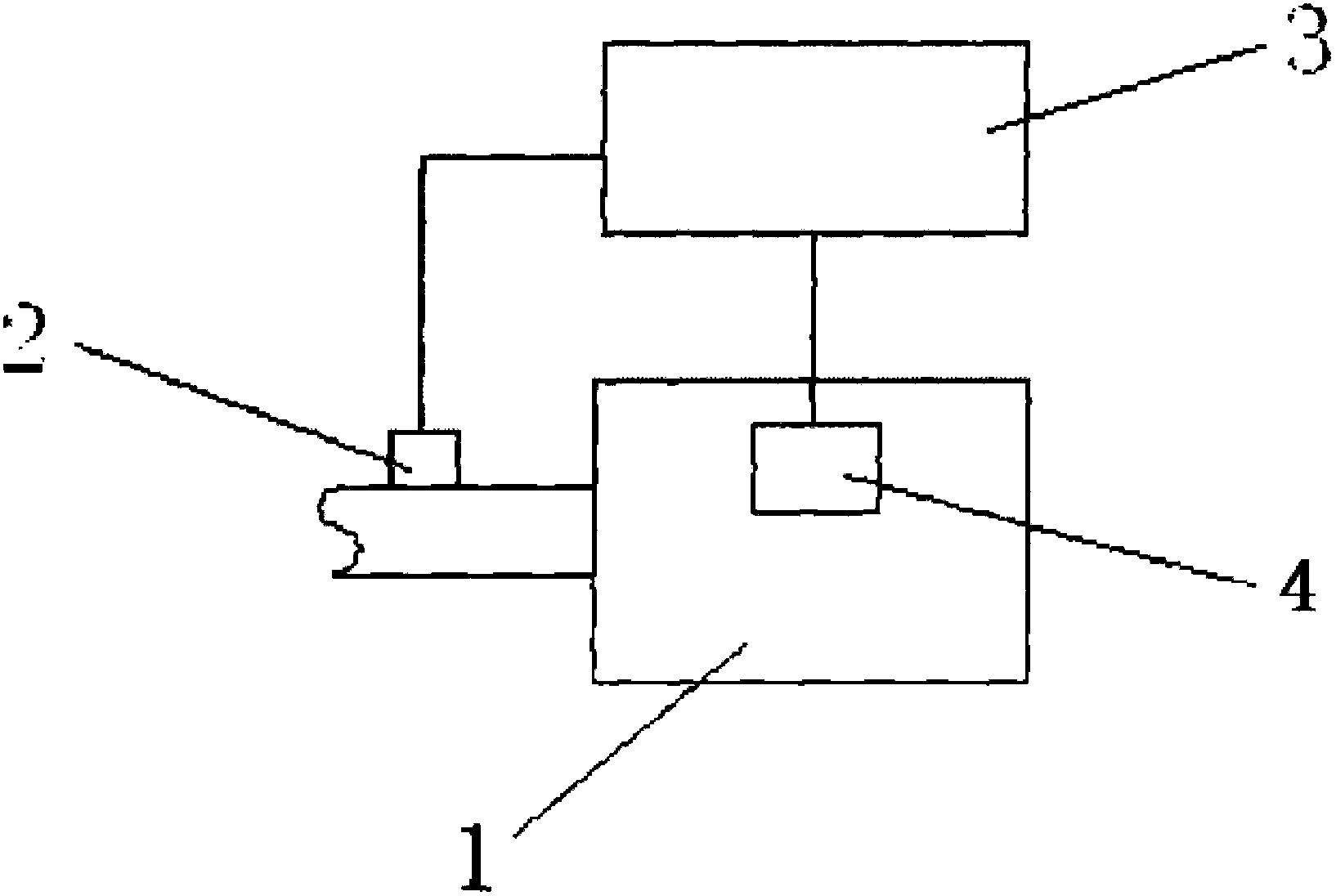

[0010] A magnetic pump with a pressure sensor as shown in Figure 1 includes a magnetic pump body 1, a motor 4 in the magnetic pump body 1 and a pressure sensor 2, and the signal output end of the pressure sensor 2 is connected to the signal input end of the brake unit 3 , the signal output terminal of the braking unit 3 is connected with the motor 4 . The braking unit 3 is a PLC system, and the PLC system controls the on-off of the motor 4 through an external relay. The PLC system sets the program. When the cooling water flow decreases, the signal collected by the pressure sensor 2 is sent to the signal input terminal of the PLC system. After the PLC system processes it, the motor 4 is cut off, and the magnetic pump stops, which protects the magnetic pump. .

[0011] The present invention has been exemplarily described above in conjunction with the accompanying drawings. Obviously, the specific implementation of the present invention is not limited by the above methods, as lo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap