Intelligent variable damping shock absorption system of commercial vehicle and shock absorber of intelligent variable damping shock absorption system

A shock absorption system and variable damping technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as poor comfort, and achieve the effect of improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

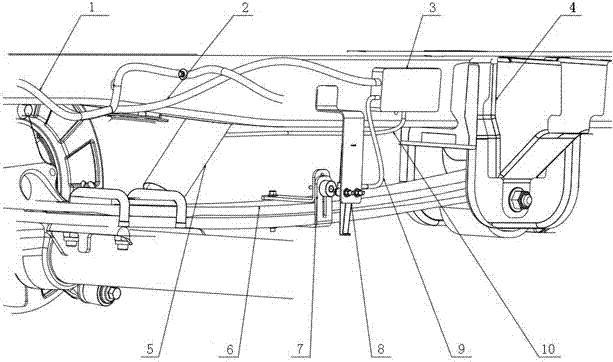

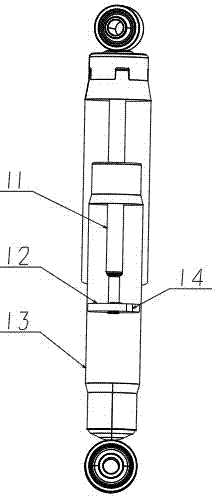

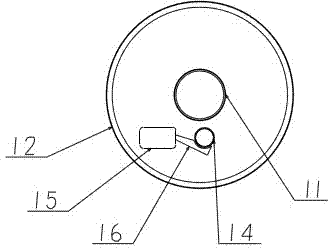

[0020] One of the shock absorbers used in the commercial vehicle intelligent variable damping shock absorption system of the present invention, such as figure 2 , 3 As shown, a steering gear 15 and a baffle plate 16 are set on the basis of the existing shock absorber, the steering gear 15 is fixedly mounted on the piston 12, and one end of the baffle plate 16 is fixedly connected with the output end of the steering gear 15, The other end of the baffle plate 16 cooperates with the liquid passing hole 14 on the piston 12, and the steering gear 15 drives the baffle plate 16 to rotate to change the effective aperture of the liquid passing hole 14; the upper part of the piston rod 11 of the shock absorber is installed on the vehicle body longitudinal beam 4 Above, the lower part of the piston cylinder 13 of the shock absorber is installed on the suspension, and the piston cylinder 13 is filled with shock absorbing oil; The piston 12 has a small liquid hole 14 specially for the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com