A locking hydraulic torque converter for construction machinery

A technology for torque converters and construction machinery, applied in mechanical equipment, fluid transmission devices, belts/chains/gears, etc., can solve the problems of low efficiency and high vehicle fuel consumption, and achieve low impact, good fuel efficiency and power. Excellent effect of resistance and torsional vibration damping characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

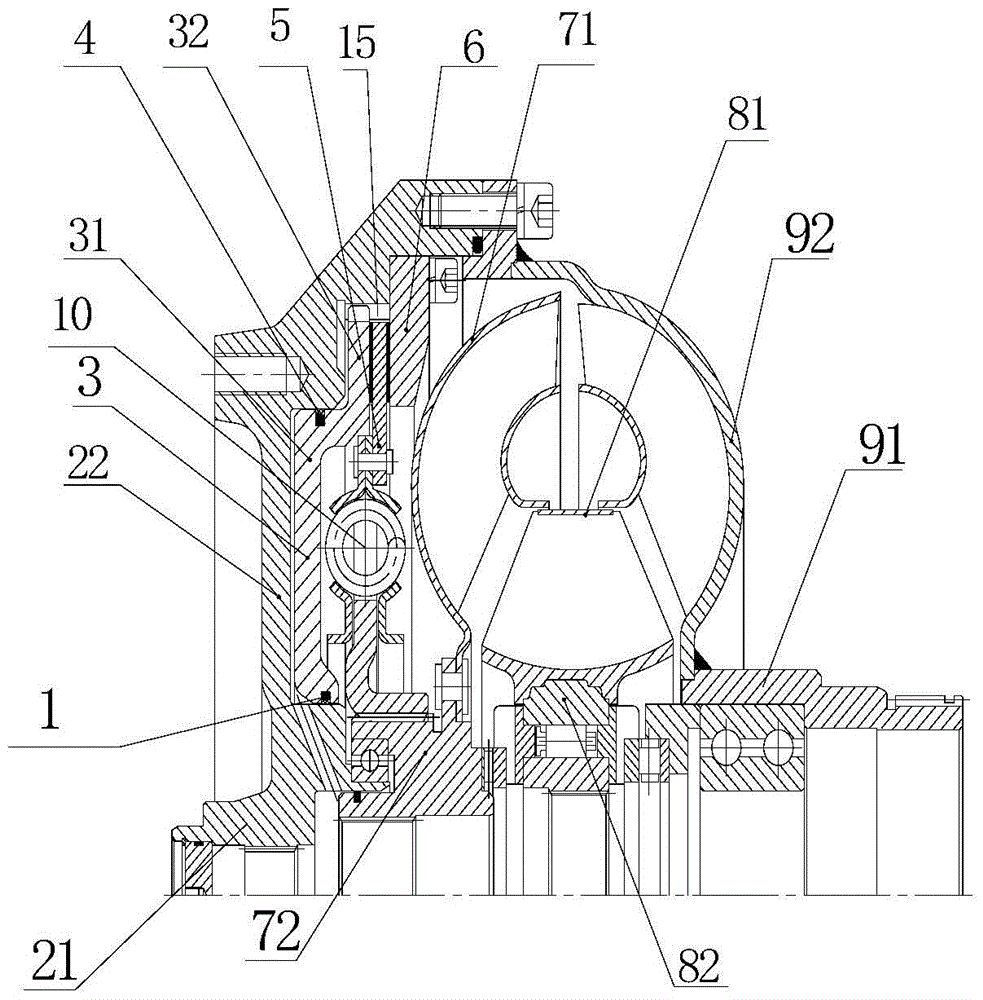

[0061] Such as figure 1 As shown, the closed-type hydraulic torque converter for engineering machinery includes a cover wheel assembly, a turbine assembly, a pump wheel assembly and a guide wheel assembly; the cover wheel assembly includes a cover wheel hub 21 and a cover wheel shell 22; the turbine assembly includes a turbine hub 72, The turbine body 71; the pump wheel assembly includes a pump wheel hub 91 and the pump wheel body 92; the guide wheel assembly includes a guide wheel body 81 and an outer race 82; and also includes a cover vortex working chamber formed by the cover wheel assembly, the turbine and the turbine hub Clutch assembly and piston assembly in.

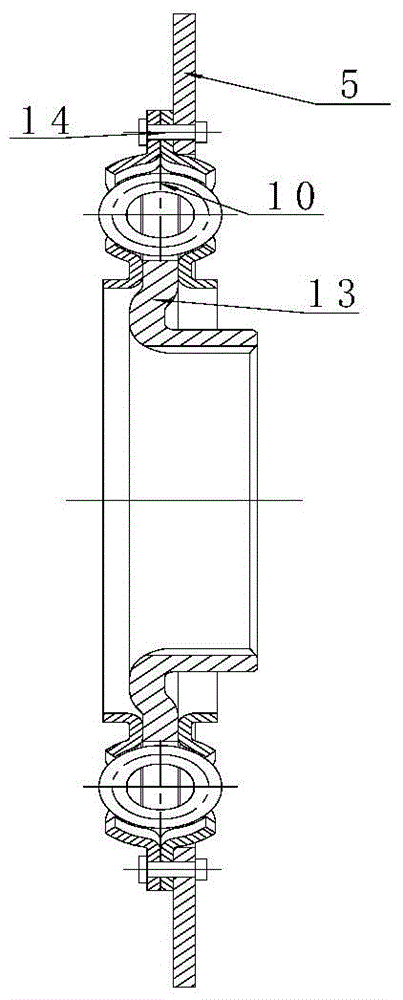

[0062] Such as figure 2 As shown, the clutch assembly includes a shock absorber 10, a friction plate 5, a disc hub 13, and a baffle 6; the piston assembly includes a piston 3, a first sealing assembly 1, and a second sealing assembly 4; the baffle 6 is fixed on the cover wheel shell 22 Above, one end of the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com