a freeze dryer

一种冻干机、冻干的技术,应用在冻干机领域,能够解决组装运输不方便、制造组装困难、制造成本高等问题,达到避免污染风险、节省制造材料、结构紧凑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

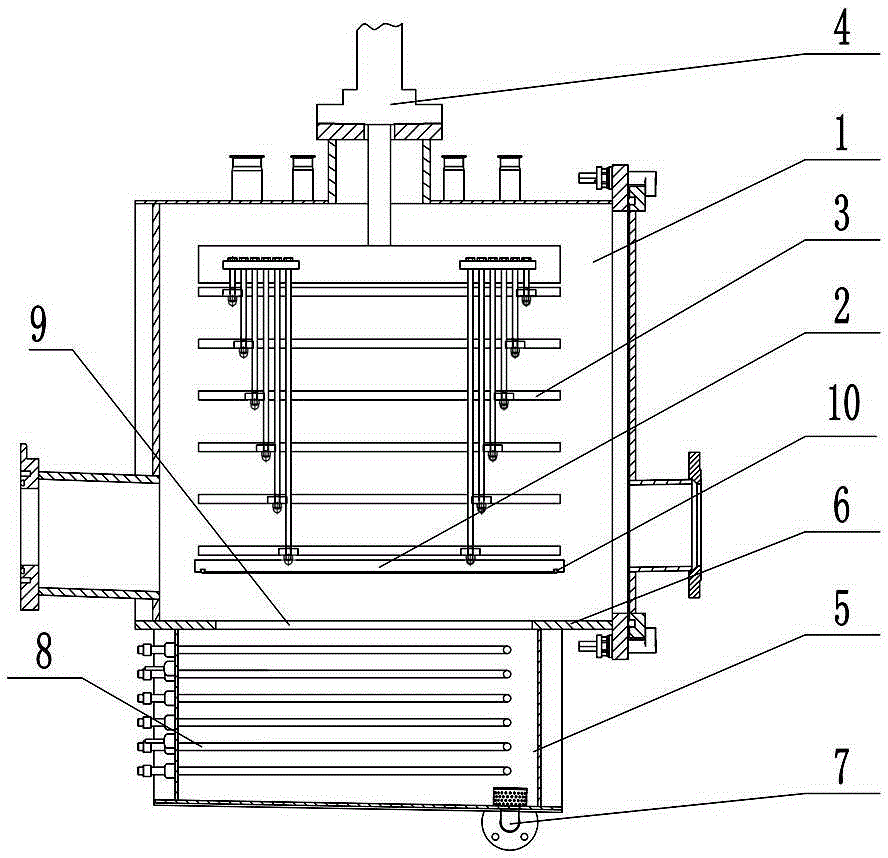

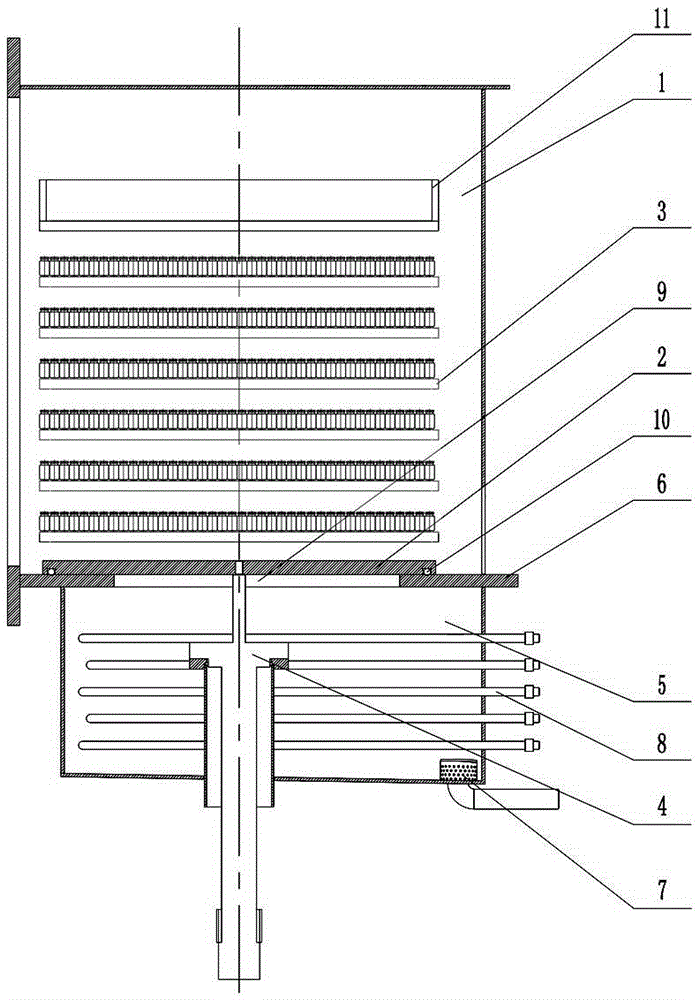

[0029] Such as figure 1 As shown, the lyophilizer of the present invention includes a freeze-drying chamber 1 and a cold trap chamber 5, and a coil 8 for refrigeration is provided in the cold-trap chamber 5; Above the multiple freeze-dried slabs 3, the top of the freeze-dried chamber 1 is provided with a lifting drive 4 for driving the support plate 2 and the freeze-dried slabs 3 up and down. The lifting drive 4 in this embodiment is an oil cylinder. During work, after the bottle body in a half-stoppered state completes freeze-drying on the freeze-drying plate layer 3, the support plate 2 and each freeze-drying plate layer 3 will move down under the drive of the lifting drive member 4, so that each freeze-drying plate layer The layers 3 are close to each other for plugging, and the rubber stopper on the bottle body is completely pressed into the bottle mouth; the support plate 2 is lowered to the bottom of the freeze-drying chamber 1 to support the freeze-dried plate layer 3 ....

Embodiment 2

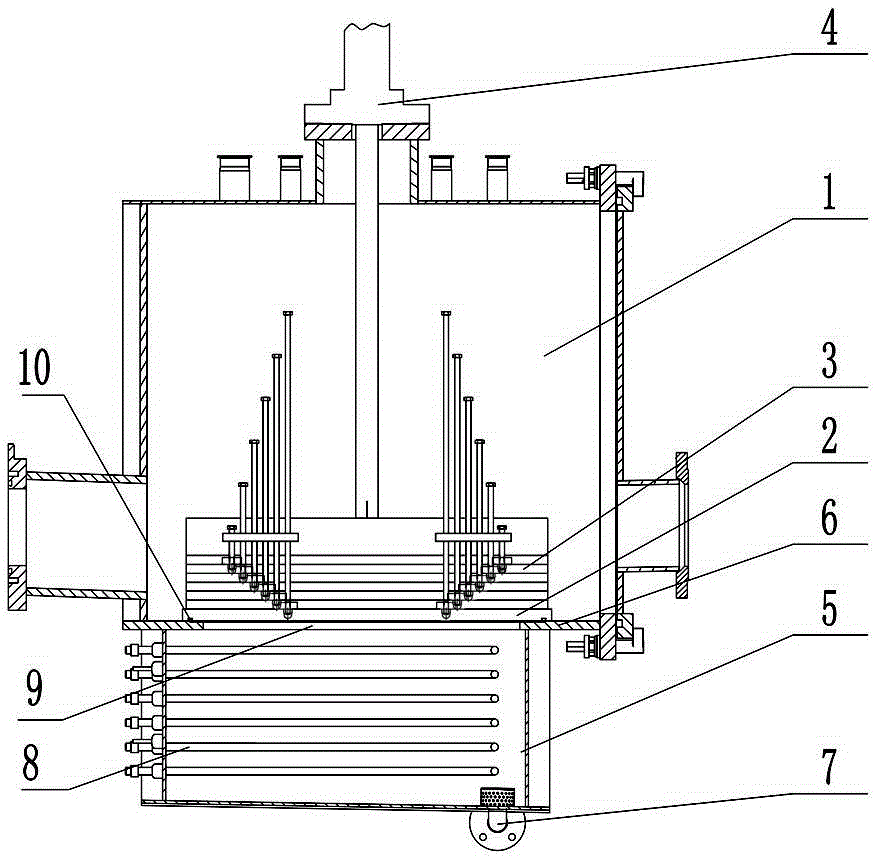

[0035] Such as image 3 and Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that in this embodiment, the lifting drive member 4 is arranged at the bottom of the cold trap chamber 5, when the support plate 2 descends to the bottom of the freeze-drying chamber 1 and covers the through When opening the hole 9, the lift driver 4 exerts a downward pulling force on the support plate 2, driving the support plate 2 to be pressed against the periphery of the through hole 9, thereby obtaining a better sealing and isolation effect, and measuring the pressure of the freeze-drying chamber 1 more accurately. liters, to accurately judge whether the freeze-drying is sufficient (the freeze-drying machine mainly evaporates the water in the mixture in the bottle, and the freeze-drying chamber 1 needs to be sealed before plugging, and the pressure rise of the freeze-drying chamber 1 should be measured, if the freeze-drying chamber 1 If the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com