A method for judging the failure type of seepage deformation of tailings silt

A technology of seepage deformation and failure type, applied in the fields of design and geotechnical engineering investigation, can solve the problems of poor sorting, narrow particle size fluctuation range, large specific gravity, etc., and achieve the effect of high accuracy and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention provides a method for judging the damage type of seepage deformation of tailings silt sand, the steps of which are as follows:

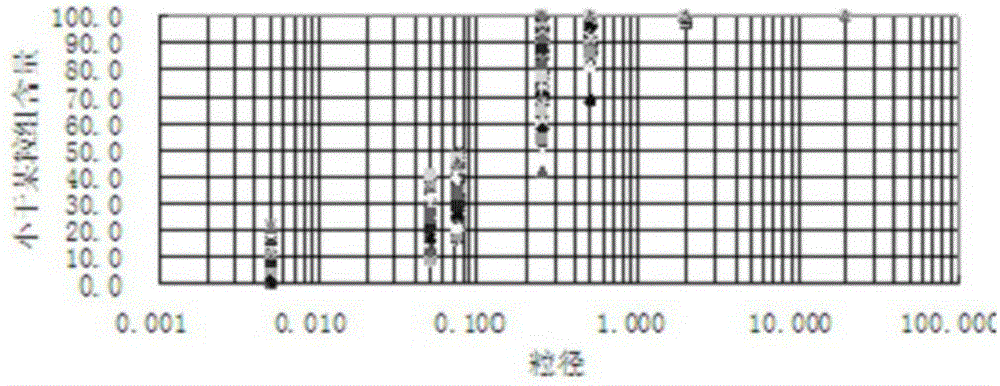

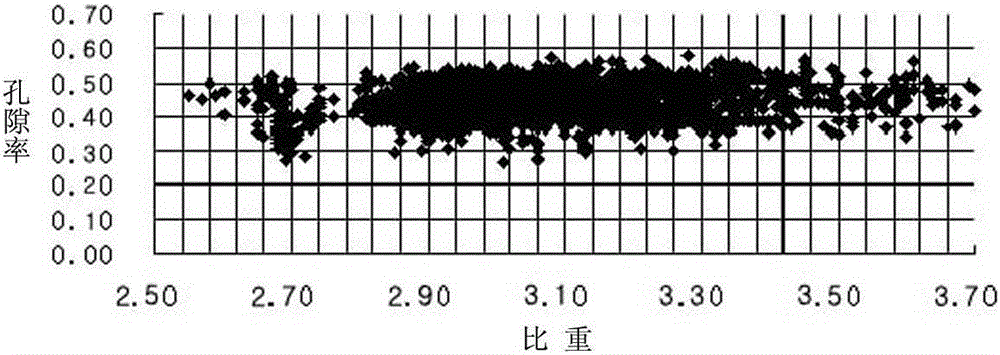

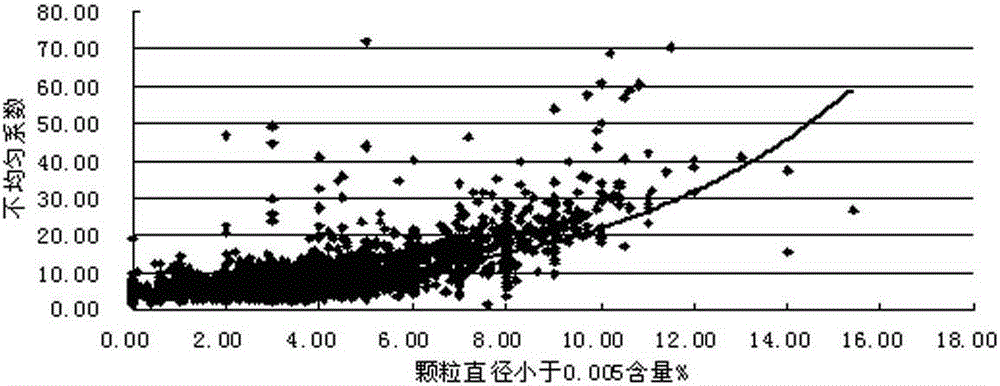

[0020] (1) Collect and sort out the laboratory test data of 40 upstream tailings accumulation dams, and analyze and count the relevant physical index characteristics of more than 4,000 groups of tailings silt in the 40 dams. The statistical results are shown in Table 1 and Table 2. Draw tailings gradation scatter diagram as shown in figure 1 , the scatter plot of porosity and specific gravity is shown in figure 2 , the scatter diagram of the relationship between the unevenness coefficient and the content of the clay group is shown in image 3 .

[0021] Among them, during the geotechnical investigation of the tailings accumulation dam, according to a certain distance (1m or 2m, generally not more than 2m), the original state of the tailings silt or the disturbed sample is sealed and packaged and sent to the laboratory;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com