Fireproof controlling cable

A control cable, fire-resistant technology, applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of unstable fire-resistant performance, loss of people's lives and property, and no high flame-retardant performance, and achieve high mechanical performance and ensure electrical conductivity. performance and high temperature performance, and the effect of ensuring high temperature fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

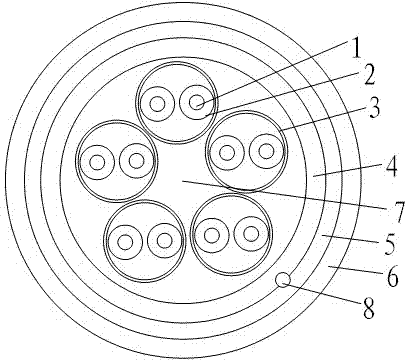

[0011] A fire-resistant control cable, including a conductor, a twisted unit, a tape layer and an outer sheath layer, the twisted unit is formed by twisting a pair of insulated wire cores, and the insulated wire core is composed of a conductor 1 outer Extruded ceramic silicone rubber insulation layer 2 is formed; the twisted unit is wrapped with 3 layers of glass fiber tape to form the main core, and the five insulated cores are combined and then wrapped with the second tape layer 4. The second tape A steel tape armor layer 5 is arranged outside the layer 4, and a ceramic silicon rubber sheath 6 is arranged outside the steel tape armor layer 5; an anti-pull steel wire rope 7 is arranged in the center of the cable, and the second cladding layer and the A copper conductor drain wire 8 is also arranged between the armor layers.

[0012] The conductor 1 is a bare copper f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap