A method of manufacturing LED male and female terminals

A manufacturing method and a technology for male terminals, which are applied in the direction of contact manufacturing, etc., can solve the problems of a lot of scraps, complicated processes, and high processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

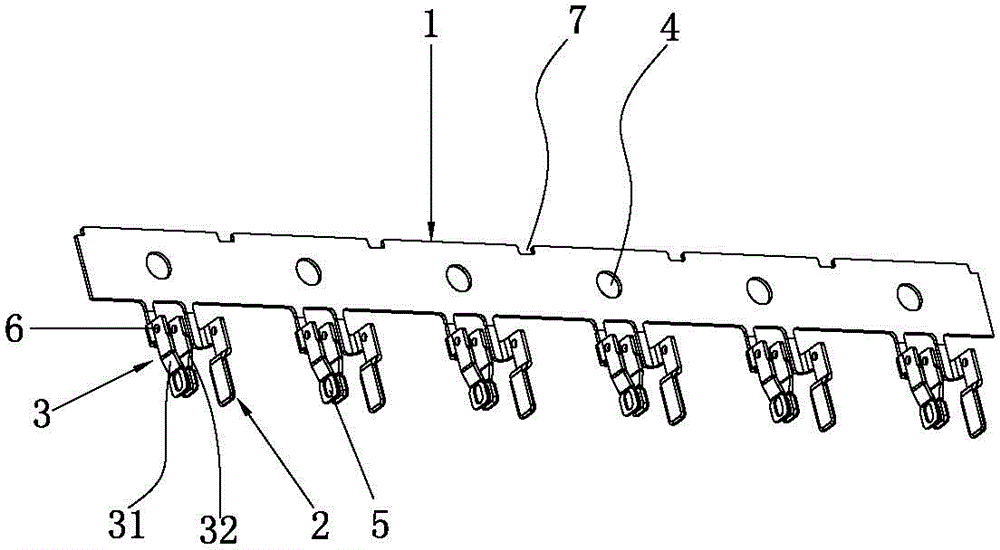

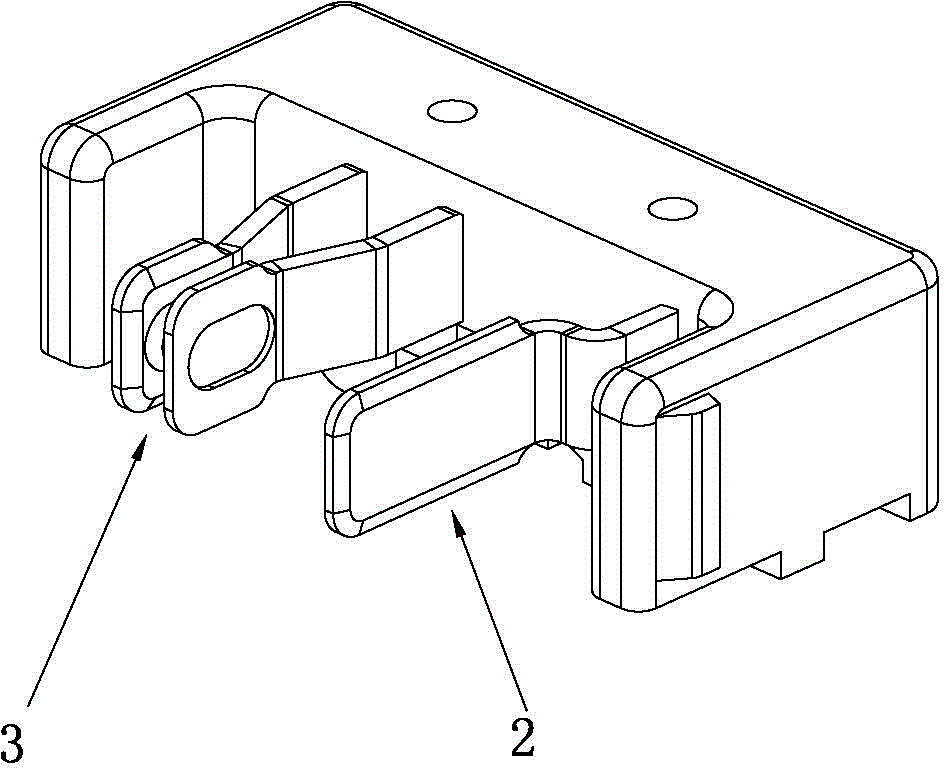

[0029] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. see Figure 1 to Figure 2 , the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] A method for manufacturing LED male and female terminals, such as figure 1 As shown, there are male and female terminal strips, the male and female terminal strips include a strip body 1 and a male terminal 2 and a female terminal 3 connected to the strip body 1, and the male terminal 2 is a bent single piece Type male terminal, the female terminal 3 is a U-shaped female terminal composed of oppositely arranged left contact elastic pieces 31 and right contact elastic pieces 32. The manufacturing method includes the following steps:

[0031] Firstly, prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com