Spray booth double chain conveyor mechanism

A double-chain conveying and spray booth technology, applied in spray booths, spray devices, etc., can solve the problems affecting the smooth operation of the skid, poor reliability of the bracket limit, affecting the spraying quality, etc., and achieve stable and reliable support for the skid and good spraying. Quality, the effect of not easy to slide left and right

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

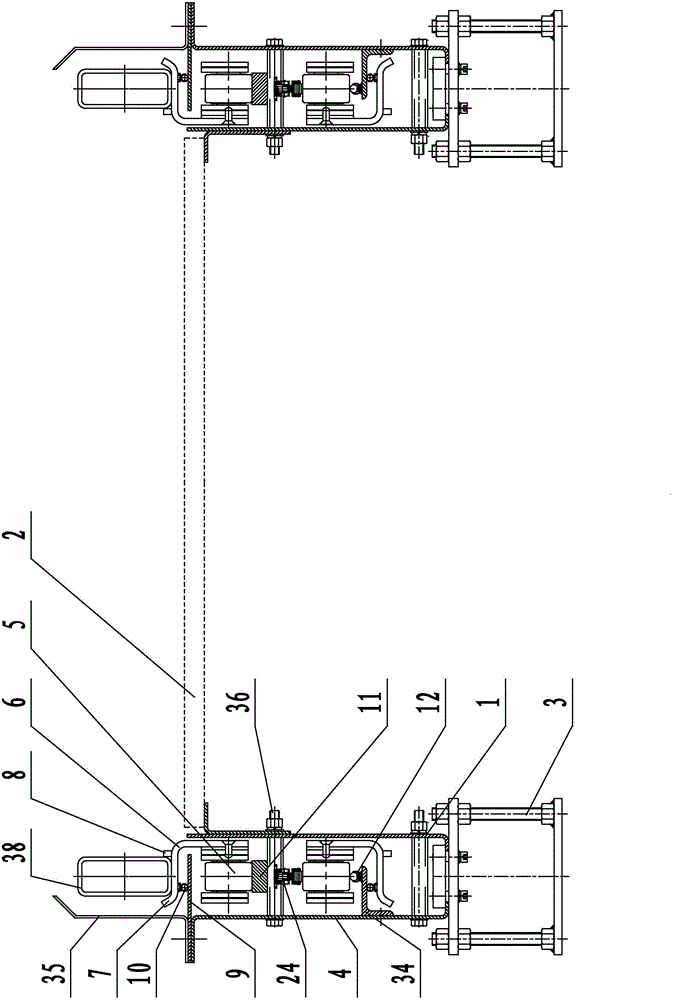

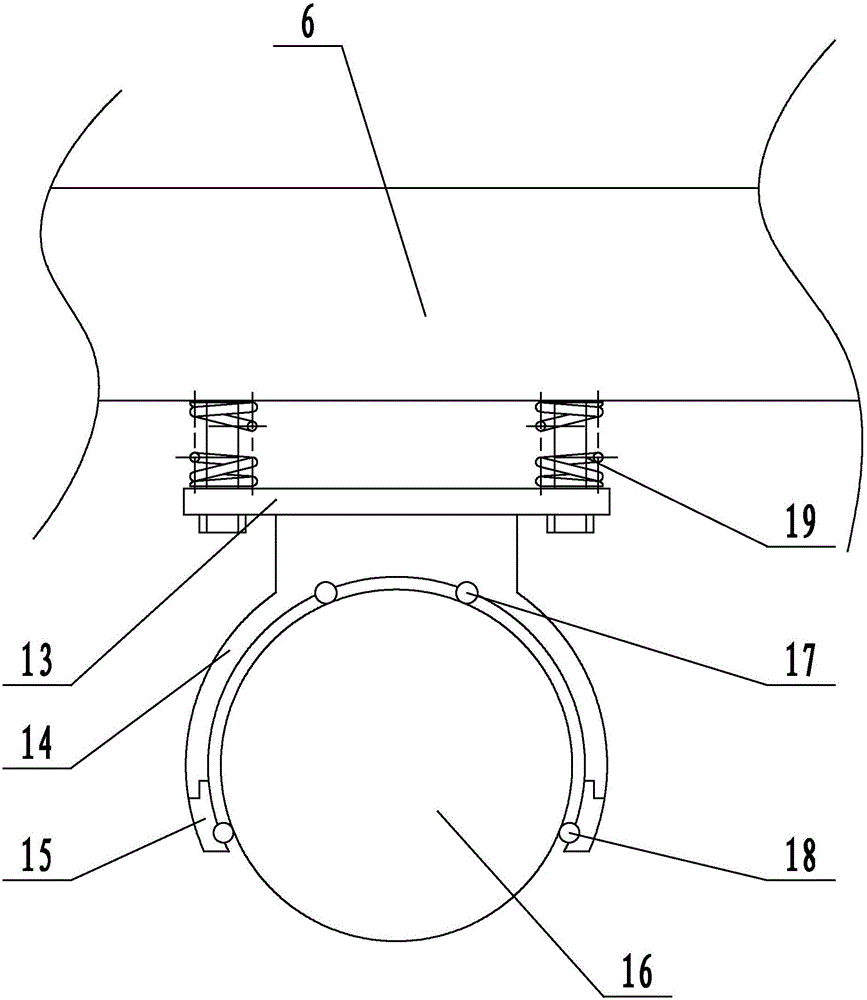

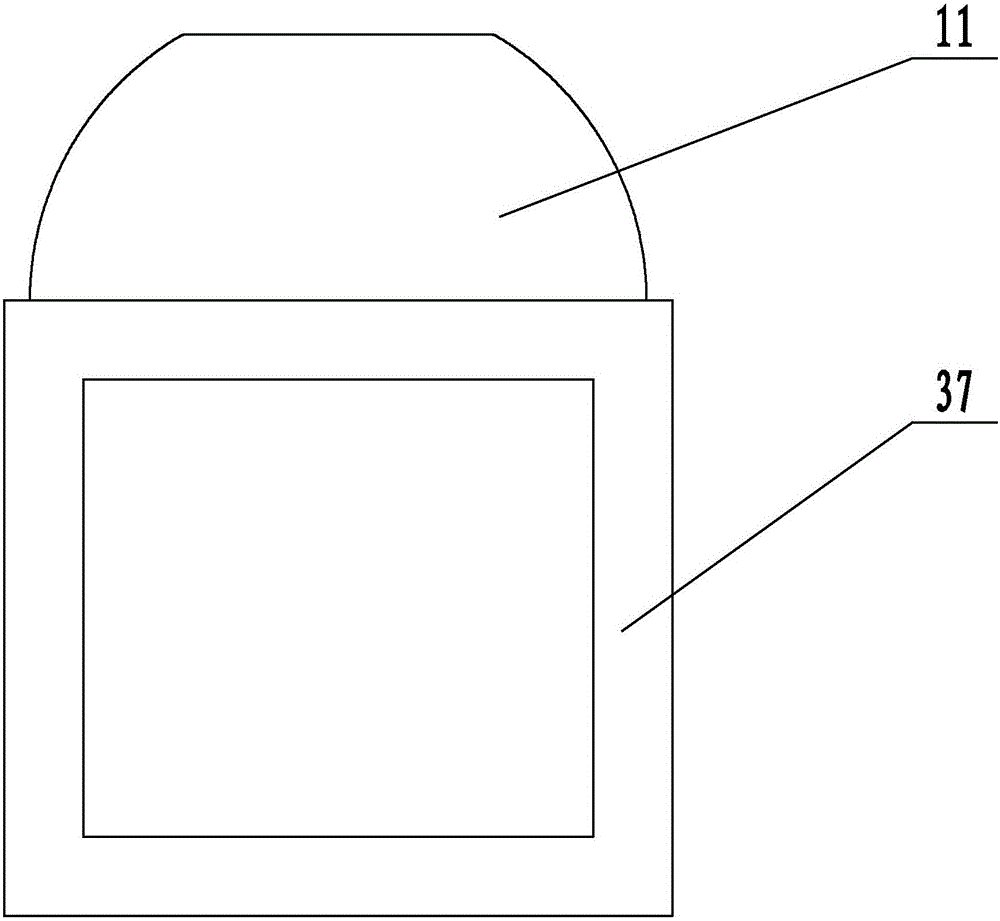

[0023] Embodiment: A kind of double-chain conveying mechanism of spray booth (see attached figure 1), including two oppositely arranged chain drive conveyor frames 1, and a connecting plate 2 is connected between the two symmetrically arranged chain drive conveyor frames. The chain transmission conveyor frame includes a base 3 and a chain installation shell 4 installed on the base. The base includes an upper base plate and a lower base plate, the upper base plate and the lower base plate are fastened by bolts, the chain installation shell is connected to the upper base plate by screws, and the lower base plate is fixedly installed on the ground. The chain mounting shell is a U-shaped structure with an upper end opening, and the chain mounting shell is provided with a transmission chain 5, which is connected with a support 6 for supporting the skid 38, and the support is an L-shaped structure, and the vertical surface of the L-shaped support is connected to the On the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com