A kind of aseptic filling valve

A technology of aseptic filling and valve body, which is applied in packaging, valve device, bottle filling, etc. It can solve the problems of low filling efficiency, achieve short response time, fast response to discharge, and increase material output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

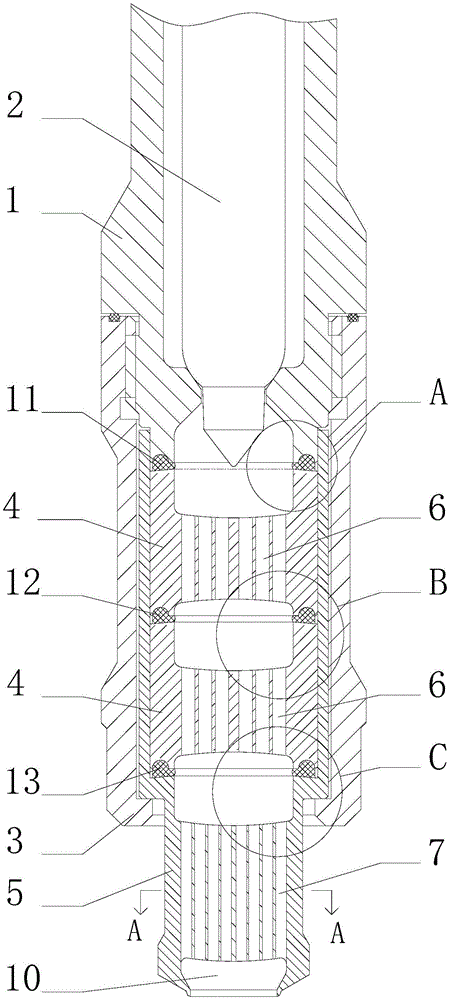

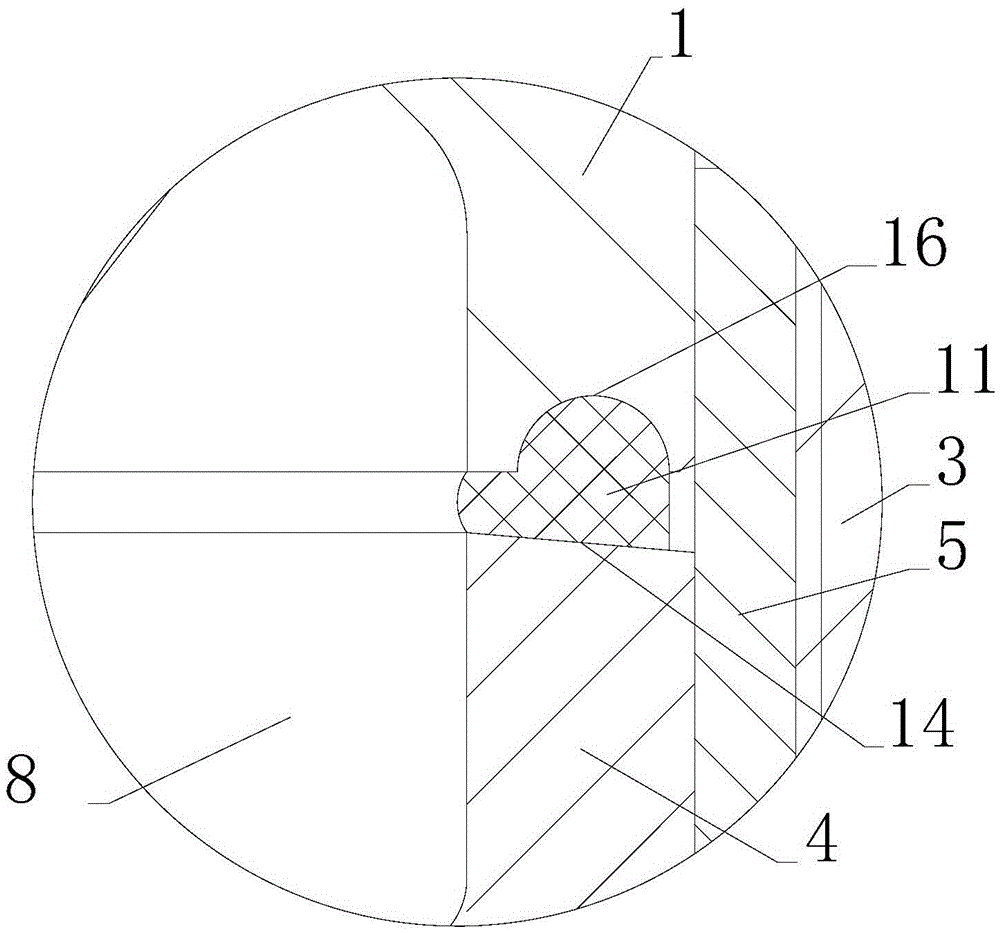

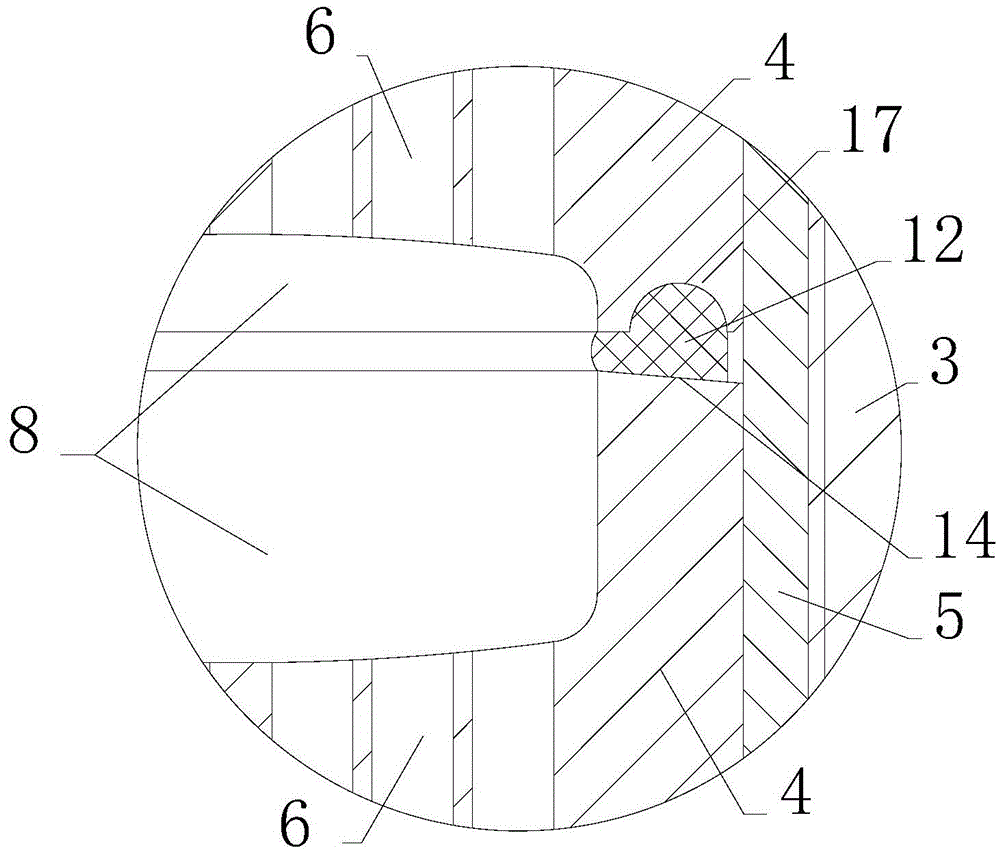

[0025] Such as figure 1 , 2 , 3, 4, and 5 show the first embodiment of the present invention.

[0026] The aseptic filling valve includes a valve body 1, a blocking rod 2, and an anti-splash assembly. The blocking rod 2 is located inside the valve body 1, and a liquid-tight connection relationship is formed between the blocking rod 2 and the valve body 1 through surface-to-surface contact. The connecting portion of the valve body 1 and the plugging rod 2 is located at the end of the valve body 1 where the discharge port is provided. The anti-splash assembly is fixedly installed on the end of the valve body 1 where the discharge port is provided.

[0027] The anti-splash assembly includes a locking sleeve 3 , a rectifying tube 4 and a drainage tube 5 . The locking sleeve 3 has a tubular structure, and the inner wall at one end is provided with an internal thread, which corresponds to the external thread of the valve body 1 at the discharge port; the other end of the locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com